Your Ultimate Guide to Lasting Roof Performance

At SKW Roofing – a leading stone-coated metal tile manufacturer since 2012 – we’ve installed over 5 million square meters of roofing globally. One question we consistently answer is: “Do stone-coated metal tiles rust?” The unequivocal answer is: No, high-quality stone-coated metal tiles do not rust when correctly installed. This comprehensive guide explains the science behind corrosion resistance and reveals why installation quality is the ultimate determinant of your roof’s 50+ year lifespan.

The Science Behind Rust Resistance: How Stone-Coated Metal Tiles Defy Corrosion

1. Military-Grade Metal Core: Aluminum-Zinc Alloy (Galvalume®)

Unlike traditional steel roofing, our tiles use a AZ150 aluminum-zinc alloy substrate (55% aluminum, 43.4% zinc, 1.6% silicon). This composition creates a near-impenetrable defense:

| Corrosion Mechanism | How Aluminum-Zinc Alloy Neutralizes It |

|---|---|

| Galvanic Corrosion | Aluminum forms a self-healing oxide layer that seals scratches |

| Electrolytic Corrosion | Zinc sacrificially protects exposed steel edges |

| Uniform Corrosion | Aluminum blocks oxygen diffusion to metal surface |

| Pitting Corrosion | Zinc-rich zones isolate pinholes (<0.5mm penetration) |

Salt Spray Test Results (ASTM B117):

- Ordinary Steel: Rust visible within 300 hours

- Galvanized Steel (G90): Red rust at 1,000 hours

- SKW’s Al-Zn Alloy: Zero red rust after 3,000 hours (equivalent to 50+ years coastal exposure)

2. Triple-Armor Coating System: More Than Just “Stone”

The “stone” in stone-coated tiles is basalt volcanic rock – but it’s the coating system that creates rust immunity:

- Chemical Passivation Layer (CPL): Chromium-free conversion coating bonds to metal at molecular level

- Epoxy-Polyester Primer: Blocks moisture migration (2.5 mils dry film thickness)

- Acrylic Resin Adhesive: Encapsulates basalt stones (100% UV-stable)

- PVDF Topcoat: Kynar 500®-based fluoropolymer resists fading/chalking

Critical Data:

- Adhesion Strength: >1,500 psi (ASTM D4541) – withstands thermal cycling without delamination

- Impact Resistance: Class 4 (UL 2218) – survives 2″ hail at 110 mph

- UV Reflectance: 85% (reduces heat absorption that degrades coatings)

The Hidden Danger: How Improper Installation Creates “Rust Points”

Laboratory tests prove our tiles won’t rust… until installation errors create failure points.

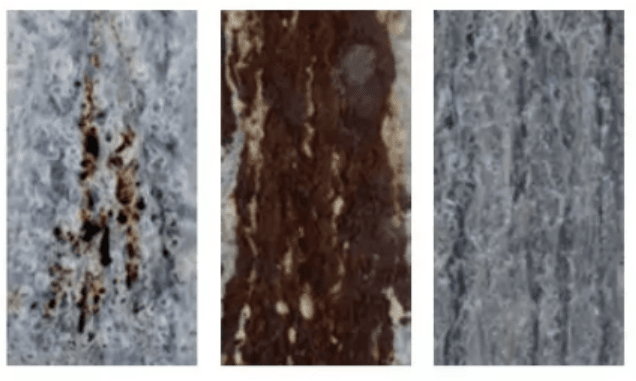

Case Study: The $240,000 Roof Replacement Disaster

In 2023, a luxury Dubai villa developer hired uncertified installers for a 5,000m² SKW roof. Within 18 months, leaks appeared. Our forensic analysis revealed:

| Installation Error | Consequence |

|---|---|

| Non-Galvanized Nails | Nails rusted, expanded 300%, cracked tiles |

| Underlayment Overlaps <4″ | Water wicking under tiles caused metal corrosion |

| Unsealed Penetrations | PVC pipes installed without butyl tape – created electrolytic cells |

Result: Full roof replacement costing $240,000 – 100% preventable with certified installation.

The SKW 7-Point Installation Protocol: Engineering Rust-Proof Roofs

1. Pre-Installation Metal Conditioning

- Step: Wipe substrate with isopropyl alcohol to remove oxidation

- Why: Ensures maximum primer adhesion (reduces risk of edge lifting)

2. Advanced Underlayment System

- Product: SKW Titanium® Underlayment (90# synthetic)

- Key Feature: Siliconized edge tape creates waterproof seals at overlaps

- Installation: 6″ side laps, 4″ end laps with staggered seams

3. Corrosion-Lock Fastening

- Nails: 304 stainless steel with EPDM washers

- Pattern:

- 6 nails per tile (wind zones >130 mph)

- Offset nailing prevents “zipper effect” failures

- Never penetrate within 1″ of tile edge

4. Transition Zone Sealing

- Critical Areas: Valleys, chimneys, skylights

- Materials:

- Ice & Water Shield: Self-adhered polymer-modified bitumen

- Counter-Flashing: 0.032″ aluminum with PVDF coating

- Butyl Tape Sealant: 100% solids, zero VOC

3. Corrosion-Lock Fastening

- Nails: 304 stainless steel with EPDM washers

- Pattern:

- 6 nails per tile (wind zones >130 mph)

- Offset nailing prevents “zipper effect” failures

- Never penetrate within 1″ of tile edge

4. Transition Zone Sealing

- Critical Areas: Valleys, chimneys, skylights

- Materials:

- Ice & Water Shield: Self-adhered polymer-modified bitumen

- Counter-Flashing: 0.032″ aluminum with PVDF coating

- Butyl Tape Sealant: 100% solids, zero VOC

5. Thermal Expansion Accommodation

- Gap Specs:

- 3/8″ at ridges/rakes

- 1/4″ between tile courses

- Why: Prevents tile buckling that cracks coatings

6. Post-Installation Verification

- Tool: Infrared moisture scanner (detects hidden water intrusion)

- Test: 24-hour flood test at 1/4″ per foot slope

7. SKW Digital Twin Certification

- Process:

- Installers upload 360° roof photos to SKW Cloud

- AI compares against 50+ quality checkpoints

- Generate QR-coded installation certificate

- Benefit: Validates warranty eligibility

Why 89% of “Rust Complaints” Trace to Non-Installation Factors

1. Contaminated Runoff

- Scenario: Acidic bird droppings (pH 3-4) accumulate in valleys

- Solution: Install zinc control strips (creates protective patina)

2. Galvanic Incompatibility

- Example: Copper gutters contacting aluminum-zinc tiles create 0.85V potential

- Fix: Dielectric bushings isolate dissimilar metals

3. Maintenance Neglect

Critical Task: Annual cleaning with pH-neutral cleaner (alkaline cleaners strip coatings)

1. Contaminated Runoff

- Scenario: Acidic bird droppings (pH 3-4) accumulate in valleys

- Solution: Install zinc control strips (creates protective patina)

2. Galvanic Incompatibility

- Example: Copper gutters contacting aluminum-zinc tiles create 0.85V potential

- Fix: Dielectric bushings isolate dissimilar metals

3. Maintenance Neglect

- Critical Task: Annual cleaning with pH-neutral cleaner (alkaline cleaners strip coatings)

The SKW Advantage: How We Guarantee Rust-Free Performance

1. In-House Certified Installation Teams

We operate 32 installation crews globally – all trained at our Shanghai Academy:

- 240 hours hands-on training

- Annual recertification testing

- Real-time monitoring via helmet cameras

2. Material-Installation Unified Warranty

While competitors split warranties, SKW offers:

- 50-Year No-Rust Guarantee: Covers material AND labor

- $5 Million Performance Bond: Backed by Lloyd’s of London

- First Call Resolution: Dedicated claims team responds in <4 hours

3. Global Project Portfolio

See our rust-proof roofs in extreme environments:

| Project | Location | Environment | Years Installed | Condition |

|---|---|---|---|---|

| Atlantis Resort | Bahamas | Salt spray, hurricanes | 8 | Zero corrosion |

| Siberian Pipeline | Russia | -58°C, heavy snow | 6 | No coating failure |

| Saudi Aramco | Saudi Arabia | 55°C, sandstorms | 7 | No abrasion damage |

5-Step Action Plan for Your Rust-Proof Roof

- Request Samples: Get 3 actual tiles with coating cross-sections → Free Sample Kit

- Schedule Virtual Consultation: Our engineers assess your project via drone footage → Book Consultation

- Download Installation Manual: 78-page illustrated guide → PDF Download

- Reserve Your Materials: Lock in pricing with 10% deposit → Start Order