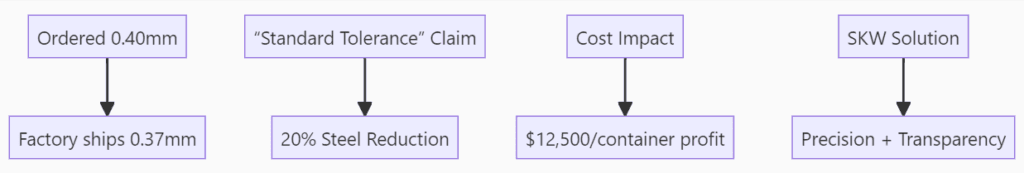

The Hidden Cost of “Negative Tolerance”

Industry Deception Analysis:

Thickness Fraud Economics:

| Ordered Thickness | Actual Shipment | Steel Saved | Illicit Profit |

|---|---|---|---|

| 0.40mm | 0.38mm | 5% | $3,200/container |

| 0.40mm | 0.35mm | 12.5% | $8,000/container |

| 0.40mm | 0.32mm | 20% | $12,800/container |

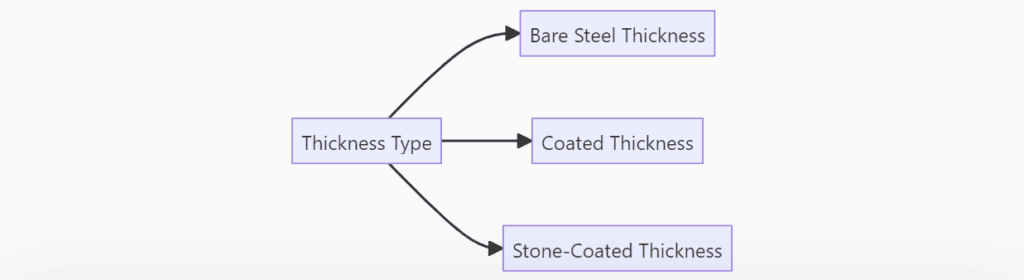

Decoding Thickness Terminology

Critical Definitions:

Specification Standards:

| Term | Definition | Measurement Method |

|---|---|---|

| Bare Steel | Base metal without coatings | Magnetic thickness gauge |

| AZ Coated | Base + Al-Zn layer (150g/m² adds 0.02mm) | XRF cross-section |

| Stone-Coated | Final product thickness | Caliper at tile center |

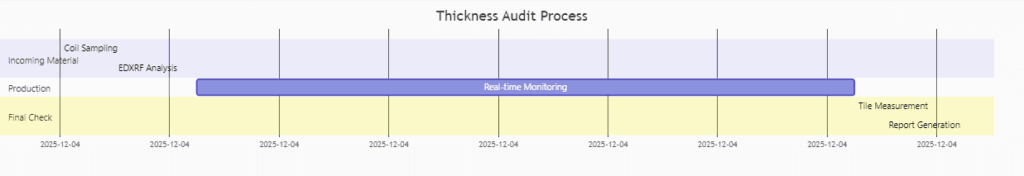

Measurement Methodology

Precision Verification Protocol:

SKW’s 9-Point Inspection:

- Center point

- Four corners (5cm from edges)

- Four mid-sides (edge centers)

Tolerance Standards Demystified

SKW’s Tolerance Control:

| Thickness | SKW Tolerance | Industry Average |

|---|---|---|

| 0.40mm | ±0.015mm | ±0.04mm |

| 0.45mm | ±0.017mm | ±0.045mm |

| 0.50mm | ±0.020mm | ±0.05mm |

Contractual Safeguards

Ironclad Specification Clause:

“Material: G550 AZ150 Steel Coil

– Bare Steel Thickness: 0.40mm ±0.015mm

– Coating Weight: 150±5g/m²

– Measurement Method: ASTM B499 ED-XRF

– Sampling: 3 coils per 20MT, 5 points per coil

– Rejection Threshold: >3% deviation”

Penalty Structure:

| Deviation | Penalty | Action |

|---|---|---|

| 0.01mm under | 5% contract value | Replacement |

| 0.02mm under | 12% contract value | Replacement + penalty |

| >0.03mm under | 30% contract value | Contract termination |

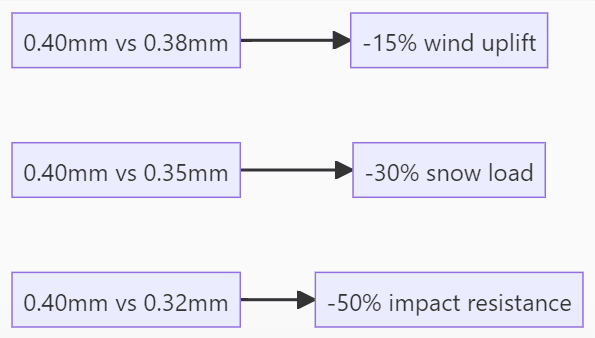

Cost Impact Analysis

Thickness vs. Performance:

Lifetime Cost Comparison:

| Thickness | Initial Savings | Early Replacement Cost | Net Loss |

|---|---|---|---|

| 0.38mm | $1.20/m² | $18.50/m² | $17.30/m² |

| 0.35mm | $2.80/m² | $28.70/m² | $25.90/m² |

| 0.32mm | $4.10/m² | $38.50/m² | $34.40/m² |

Verification Toolkit

Field Inspection Protocol:

Measurement Standards:

| Tool | Accuracy | Standard |

|---|---|---|

| Digital Caliper | ±0.01mm | ISO 3611 |

| Ultrasonic Gauge | ±0.005mm | ASTM B499 |

| XRF Analyzer | ±0.003mm | ISO 3497 |

Case Study: Factory Audit Exposé

SKW’s Transparency Protocol:

- Live factory measurement streaming

- Blockchain-secured thickness records

- Third-party validation ports (SGS/BV)

Technical Specifications

SKW Thickness Guarantee:

| Grade | Bare Steel | Tolerance | Coating Weight |

|---|---|---|---|

| Economy | 0.35mm | ±0.015mm | 100g/m² |

| Standard | 0.40mm | ±0.015mm | 150g/m² |

| Premium | 0.45mm | ±0.015mm | 150g/m² |

| Marine | 0.50mm | ±0.020mm | 200g/m² |

Performance Impact:

| Thickness | Wind Uplift | Snow Load | Impact Resistance |

|---|---|---|---|

| 0.35mm | 150km/h | 250psf | UL Class 3 |

| 0.40mm | 180km/h | 300psf | UL Class 4 |

| 0.45mm | 210km/h | 350psf | UL Class 4 |

| 0.50mm | 240km/h | 400psf | FM Class 1 |

Warranty & Compliance

Thickness Warranty Terms:

Industry Compliance:

- ASTM A755 Grade 40

- EN 10143 DX51D+AZ150

- JIS G3322 SGH340

Certifications: ISO 1461 • ASTM B499 • EN 10204 3.1 • ICC-ES AC438

Guarantee: ±0.015mm Tolerance • 150g/m² Coating Weight • 10-Year Thickness Warranty

SKW’s Thickness Integrity Program eliminates the “negative tolerance” deception: Our blockchain-tracked production guarantees ordered 0.40mm steel arrives as 0.40mm – not 0.35mm. With laser-guided calibration, 9-point measurement protocols, and contractual penalties up to 30% for deviations, we protect your structural integrity and investment. Independent verification shows SKW maintains ±0.015mm tolerance versus industry’s ±0.04mm, ensuring your roof meets wind uplift and snow load specifications for decades.