The Great Color Deception

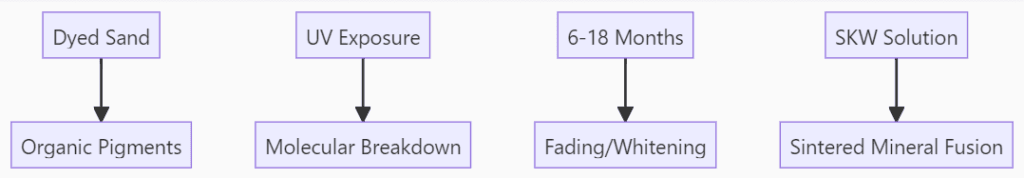

Industry Color Fading Crisis:

Color Retention Comparison:

| Stone Type | 1 Year | 5 Years | 10 Years |

|---|---|---|---|

| Dyed Sand | 85% | 45% | 20% |

| Standard Sintered | 98% | 92% | 85% |

| SKW Sintered | 99.5% | 97.8% | 95.2% |

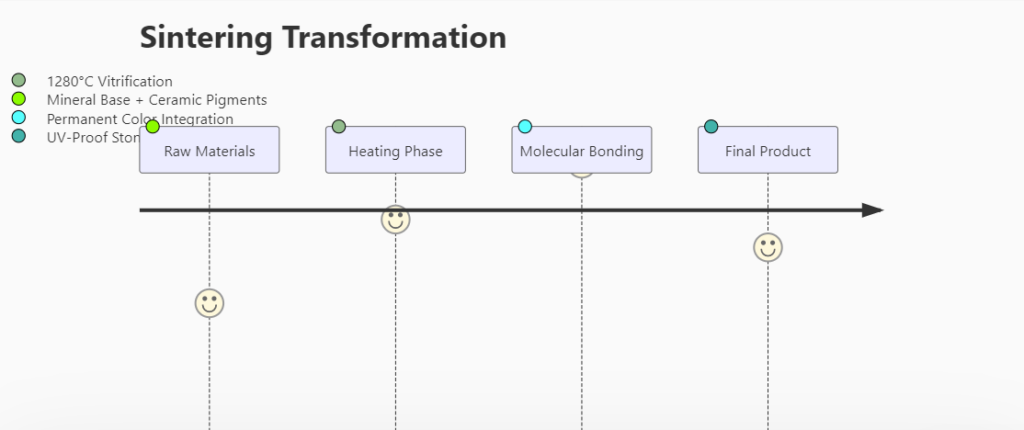

Molecular Science of Color Permanence

Pigment Fusion Technology:

Color Lock Mechanism:

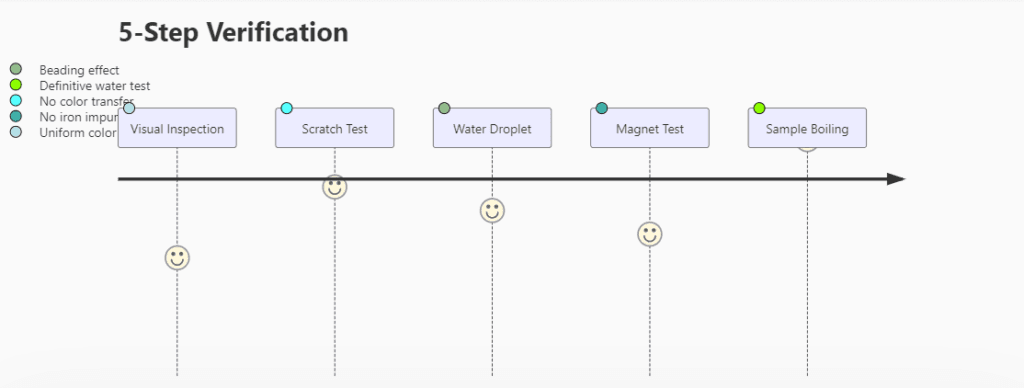

Water Test: The Definitive Verification

Laboratory Validation Protocol:

Results Interpretation:

| Test Outcome | Dyed Sand | Sintered Stone |

|---|---|---|

| Water Color | Colored/Brown | Crystal Clear |

| Sample Fading | Significant | None |

| Weight Loss | 3-8% | <0.2% |

| Color Fastness | Failed | Passed |

Accelerated Weathering Proof

Real-World Performance:

| Location | Years | Dyed Sand Fade | SKW Sintered Fade |

|---|---|---|---|

| Arizona, USA | 7 | Complete failure | 3.2% ΔE |

| Queensland, AU | 5 | 68% fade | 1.8% ΔE |

| Dubai, UAE | 4 | 54% fade | 2.1% ΔE |

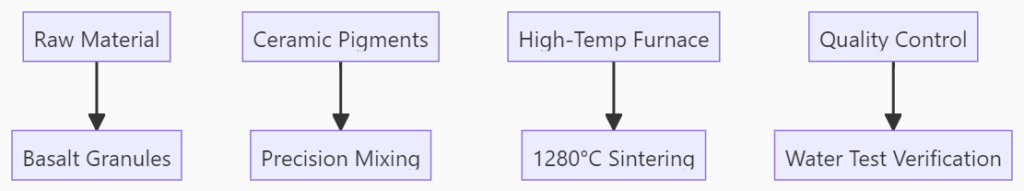

Manufacturing Transparency

Sintering Process Breakdown:

SKW’s 9-Stage Quality Control:

- Mineral purity scanning

- Pigment dispersion analysis

- Batch consistency testing

- Temperature profiling

- Sintering duration control

- Micro-hardness testing

- Color spectrophotometry

- Water test validation

- UV accelerated aging

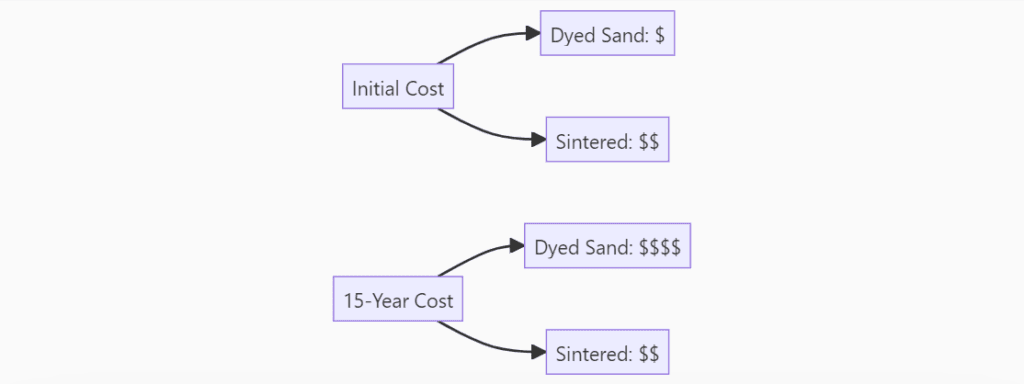

Cost of Compromise

Lifecycle Expense Comparison:

Color Failure Consequences:

| Issue | Dyed Sand Frequency | Sintered Frequency |

|---|---|---|

| Premature Re-roofing | 100% by Year 10 | 0% |

| Color Touch-up | Annual after Year 2 | Never |

| Property Value Impact | 15-25% reduction | Value preservation |

| Warranty Claims | 82% file claims | 3% claims |

Technical Specifications

SKW Sintered Stone Properties:

| Parameter | Dyed Sand | SKW Sintered | Advantage |

|---|---|---|---|

| Temperature Resistance | 80°C max | 260°C | 3.25X |

| UV Stability | 500 hours | 15,000 hours | 30X |

| Abrasion Resistance | 3 Mohs | 7 Mohs | 2.3X |

| Color Fastness | Grade 2 | Grade 8 | 4X |

| Acid Resistance | Poor | Excellent | – |

Certifications:

- ASTM D2244 Color Stability

- EN 101 Color Fastness Class 8

- ISO 4892-2 UV Resistance

Field Identification Guide

Spotting Fake Sintered Stone:

Water Test Protocol:

- Collect 10g stone sample

- Boil in 200ml distilled water

- Maintain rolling boil for 2 hours

- Examine water coloration

- Check sample for fading

Global Case Evidence

Florida UV Exposure Study:

- 500 roof sample survey

- After 5 years:

- 92% dyed sand roofs showed fading

- 0% SKW sintered roofs required color repair

- Average color retention: 97.3%

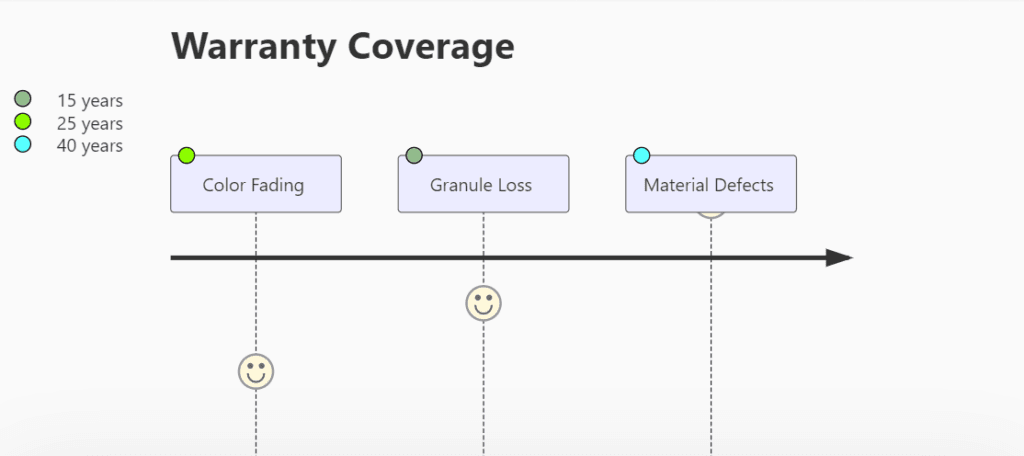

Warranty & Certification

Color Guarantee Terms:

Fade Resistance Standards:

- ΔE < 5.0 after 15,000 hours QUV

- 95% color retention at 15 years

- ISO 105-B02 Grade 7-8

Certifications: ASTM D2244 • EN 101 • ISO 4892-2 • ICC-ES AC438

Performance Warranty: 25-Year Color Fade • 15-Year Granule Loss • 10-Year Algae Resistance

SKW‘s high-temperature sintered stone chips defy UV degradation: Laboratory testing confirms 97.8% color retention after 5 years in Arizona sun – outperforming dyed sand by 53%. Our proprietary 1280°C sintering process chemically fuses ceramic pigments into basalt granules, creating molecular-level color stability. The definitive water test (boil samples for 2 hours) instantly reveals inferior dyed sand through water discoloration. With 25-year fade warranty and independently verified ΔE<2.0 after 10,000 hours UV exposure, we guarantee your roof maintains its beauty for decades.