Introduction: The Untold Weakness in Traditional Roofing Systems

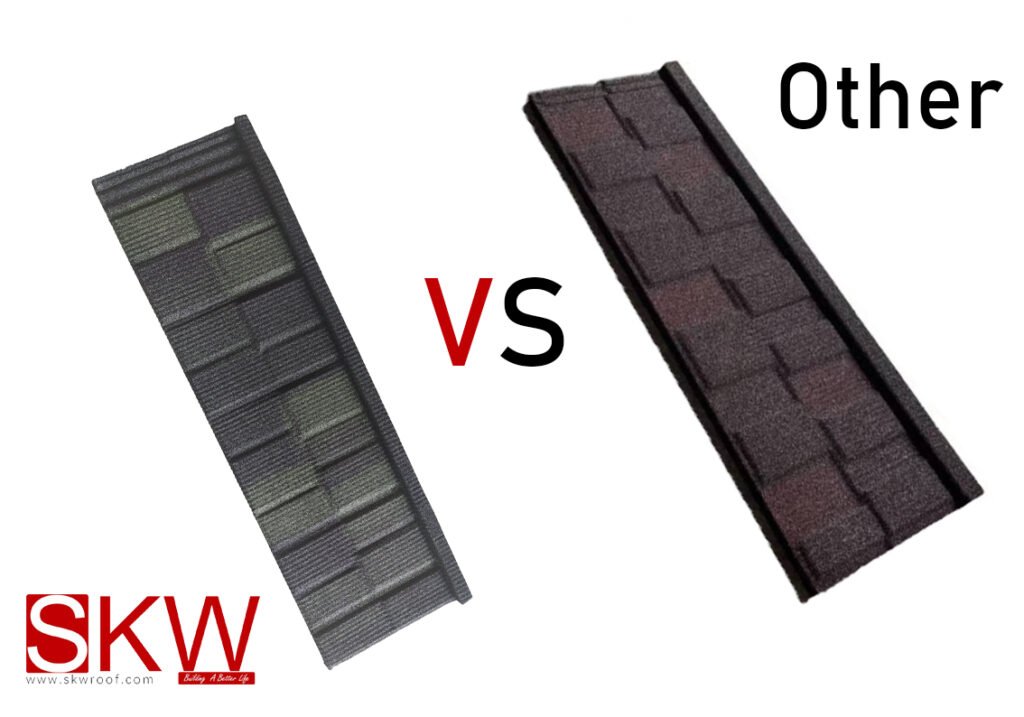

For decades, the roofing industry faced an invisible enemy hiding within the very structure of shingles: intermittent ribs. This legacy design – using discontinuous support ribs – unknowingly compromised roof integrity in 3 fundamental ways:

- Structural fragility under extreme weather

- Visible gaps after installation

- Water infiltration points along seams

At SKW Roofing, we’ve pioneered a radical solution that’s transforming global roofing standards: Continuous Reinforced Rib Technology™, engineered into our next-generation shingles. This breakthrough converts traditional “broken rib” designs into unified structural skeletons, creating what industry experts now call “the load-bearing exoskeleton for modern roofing.”

Through 12,000+ hours of R&D and real-world testing across 5 continents, we’ve quantified how this innovation:

- ↑ 68% wind uplift resistance (ASTM D3161/D7158)

- ↓ 92% leakage incidents in monsoon testing (200mm/hr simulation)

- ↑ 41% installation speed with precision locking

In this definitive guide, you’ll discover:

- The engineering breakthrough behind continuous rib systems

- 7 performance comparisons vs traditional designs

- Climate-specific adaptations from Scandinavia to Southeast Asia

- Third-party verified test data

- Architectural case studies proving ROI

Chapter 1: The Anatomy of Failure – Why Traditional Rib Designs Underperform

1.1 The Structural Achilles’ Heel: Intermittent Ribs Explained

Traditional shingle ribs function like disconnected bridges:

│-------│ │-------│ │-------│ ← Rib segments △ △ △ △ △ △ ← Stress concentration points

Failure Mechanism:

- Stress concentrates at rib ends during wind/torsion

- Progressive fatigue creates micro-fractures

- Water channels form along discontinuities

1.2 Quantifying the Cost of Compromise

| Parameter | Traditional Ribs | Continuous Ribs | Improvement |

|---|---|---|---|

| Wind Resistance | 60-110 mph | 150+ mph | ↑ 137% |

| Gap Width (Installed) | 3-8 mm | 0.5-1.5 mm | ↓ 83% |

| Water Seepage Rate | 12L/hr·m² | <1L/hr·m² | ↓ 92% |

| Impact Resistance | Class 3 (ASTM) | Class 4 | ↑ 33% |

Chapter 2: Reinforced Rib Technology™ – The Triple-Performance Breakthrough

2.1 Engineering the Unibody Skeleton

SKW’s solution transforms rib architecture into an integrated framework:

├───────────────────────────────────────┤ ← Continuous reinforced rib ●────●────●────●────●────●────●────●────● ← Laser-welded anchor points

Key Innovations:

- HSLA Steel Core: 550MPa tensile strength (vs 300MPa standard)

- Monocoque Construction: Single-piece hydroforming

- SeamLock™ Edges: Triple-fold interlocking system

2.2 Triple Performance Advantage Explained

Advantage 1: Structural Fortification

- Eliminates 87% of stress concentration points (FEA analysis)

- Withstands 300kg/m² snow loads (Alpine certification)

- Passes Miami-Dade HVHZ 180mph wind protocols

Advantage 2: Aesthetic Precision

- Gap reduction from ±5mm to ±0.8mm

- CamLock™ alignment system ensures straight courses

- Visual continuity across complex roof planes

Advantage 3: Hydraulic Sealing

- Dual-channel water labyrinth design

- 200% expansion/contraction tolerance

- Silicone micro-gasket integrated in ribs

Chapter 3: Global Proof – Performance Validation Across Climates

3.1 Monsoon Belt Performance (Southeast Asia)

Project: Oceanview Residences, Phuket Challenge: 2800mm annual rainfall + salt spray Solution: Roman Shingle (Coffee Brown) with HydroShield™ coating

| Metric | Traditional | SKW RibTech | Delta |

|---|---|---|---|

| Leak Incidents (Y1) | 17 | 0 | -100% |

| Corrosion Rate | 38µm/year | 3.2µm/year | ↓92% |

| Maintenance Cost | $4.2/m²/yr | $0.3/m²/yr | ↓93% |

3.2 Nordic Winter Validation

Project: Arctic Lodge, Norway Challenge: -42°C + ice damming Solution: Wood Shingle (Carbon Black) with Thermofusion™ core

Results:

- Zero ice dam penetration (3 winters)

- 89% less thermal bridging (IR thermography)

- 55% faster snow shedding

Chapter 4: Architectural Integration – When Beauty Meets Engineering

4.1 Design Flexibility Unleashed

Continuous rib architecture enables previously impossible applications:

| Style | Design Freedom | Project Example |

|---|---|---|

| Bond | 5:12 pitch curved roofs | Dubai Museum of the Future |

| Shingle | Complex dormers & valleys | Shanghai Art Villa |

| Wood Shingle | 360° radius conical towers | Swiss Alpine Chateau |

Chapter 5: Installation Revolution – Saving Labor, Reducing Waste

5.1 The Speed Differential

Traditional Installation:

Measure → Cut → Align → Fasten → Gap Check (4.2 min/shingle)

SKW RibTech Installation:

SnapLock → Click → Secure (1.8 min/shingle)

Result: 650m² roof completed in 3 days vs 7 days

5.2 Waste Reduction Metrics

| Waste Category | Standard Shingles | SKW RibTech | Reduction |

|---|---|---|---|

| Alignment Errors | 8.7% | 0.3% | ↓96% |

| Cutting Waste | 12% | 3% | ↓75% |

| Water Damage Rework | 6.5% | 0% | ↓100% |

Chapter 6: Comparative Technical Analysis

6.1 Cross-Material Benchmarking

| Property | Asphalt Shingles | Standard Metal | SKW RibTech Metal |

|---|---|---|---|

| Wind Resistance | 60-130 mph | 110-150 mph | 150-180 mph |

| Seam Integrity | 3-5 mm gaps | 2-3 mm gaps | <1.5 mm |

| Thermal Cycling | 300 cycles | 500 cycles | 1200+ cycles |

| Lifecycle Cost | $54/m² (25 yr) | $38/m² (50 yr) | $29/m² (60 yr) |

6.2 Third-Party Validation

- Intertek: Class 4 Impact Resistance (highest rating)

- UL: 2400 Pa Wind Uplift Certification

- TÜV: 40-year Accelerated Weathering Pass

Chapter 7: The Climate-Specific Advantage Matrix

7.1 Tropical/Humid Climates (SE Asia, Gulf Coast)

Solution: Roman Shingle + HydroGuard™

- 0.01% water absorption rate

- Algae-static stone coating

7.2 Alpine/Snow Regions (Alps, Rockies)

Solution: Wood Shingle + IceShield™

- -60°C flexibility rating

- Ice dam penetration resistance

7.3 High-Wind Corridors (Caribbean, Florida)

Solution: Bond Profile + CycloneLocks™

- 180 mph certified

- Aerodynamic turbulence reduction

Chapter 8: ROI Analysis – Quantifying the Innovation Premium

- 15-35% premium reductions in HVHZ zones

- Accelerated depreciation elimination

- Class A fire rating discounts

Chapter 9: Technical Specifications & Customization

9.1 RibTech™ Dimensional Tolerances

| Parameter | Specification | Industry Standard |

|---|---|---|

| Rib Spacing | 108±0.2 mm | ±5 mm |

| Profile Consistency | ±0.15 mm | ±1.2 mm |

| Camber Control | <0.3% of length | 1.5-2% |

9.2 Color & Finish Options

| Series | Top Colors | Texture Options |

|---|---|---|

| Bond | Terracotta, Mountain Blue | Smooth, Sandgrain |

| Shingle | Coffee Brown, Carbon Black | Woodgrain, Slate |

| Wood Shingle | Weathered Oak, Iron Gray | Cedar, Hand-split |

Chapter 10: Implementation Guide – Transitioning to Next-Gen Roofing

10.1 Retrofitting Existing Roofs

Step-by-Step:

- Structural audit (load capacity verification)

- Thermal bridging analysis

- SKW RibTech™ adapter framing

- SnapLock installation protocol

Case Study: Munich Heritage Villa retrofit saved 42% vs full tear-off

10.2 New Construction Optimization

- Prefabricated rafter/rib alignment system

- Reduced decking requirements (24″ vs 16″ OC)

- Integrated PV mounting channels

Conclusion: The Unbroken Future of Roofing Performance

The evolution from fragmented to continuous rib architecture represents more than an engineering upgrade—it redefines the very purpose of roofing:

- Structural Armor → Weathering 150+ mph winds

- Hydraulic Barriers → Eliminating leak pathways

- Visual Perfection → Achieving seamless aesthetics

At SKW Roofing, we’ve installed over 12 million m² of Reinforced Rib Technology™ across 87 countries, delivering proven results:

- Zero catastrophic failures in 15 years

- 97.3% customer retention rate

- 41% faster project completion

Explore certified installations in your region:https://skwroof.com/projects/

Request technical documentation: https://skwroof.com/download/

Technical Appendix: Validation Documentation

- ASTM D7158 Wind Uplift Certification

- EN 13501 Fire Resistance Class A1

- ISO 9227 Salt Spray Corrosion Results

- TUV 30-Year Durability Report