The $12 Billion Roofing Dilemma: Why “Premium” Doesn’t Always Mean Better

In luxury roofing, aluminium has long worn the crown. But beneath its gleaming surface lies a hidden cost crisis:

- 3-5X price premiums versus advanced alternatives

- Structural limitations for complex architectural designs

- Hidden maintenance traps in coastal and industrial zones

At SKW Roofing, we’ve engineered a solution that outmaneuvers aluminium where it matters most. Our stone coated metal roofs with Continuous RibTech™ deliver: ✅ 50-year lifespan matching premium aluminium ✅ 42% lower installed cost ✅ Unlimited design flexibility

Through 2,357 comparative installations across 31 countries, here’s what the data reveals…

Chapter 1: The 4 Aluminum Tile Pain Points You Can’t Ignore

1.1 The Cost Avalanche (Why Aluminium Breaks Budgets)

| Cost Component | Aluminium Tile | SKW Stone Coated | Savings |

|---|---|---|---|

| Material (per m²) | 35−35−55 | 12−12−18 | 67% |

| Structural Support | 22−22−40/m² | 0−0−8/m² | 82% |

| Installation Labor | 15−15−25/m² | 8−8−12/m² | 53% |

| Total Installed | 72−72−120/m² | 28−28−42/m² | ↓58% |

Source: 2024 Global Roofing Cost Index (GRCI)

1.2 The Design Compromise Dilemma

Aluminium’s low malleability forces architects into concessions:

- Limited curvature (≥3m radius)

- Maximum 25° pitch for concealed fixing

- Flat-plane dominance (no complex dormers)

Case Study: Dubai Marina Villa

- Architect’s vision: Flowing organic roof forms

- Aluminium limitation: $127,000 structural reinforcement

- SKW solution: Free-form bending with no support upgrades

1.3 Hidden Corrosion Risks

Contrary to myths, aluminium suffers galvanic corrosion when:

- Contacting copper flashings (pH<4.5 runoff)

- Exposed to marine aerosols (Cl⁻ penetration)

- Installed with carbon steel fasteners

Accelerated Testing Results (ISO 9227):

| Condition | Aluminium Mass Loss | SKW CeramiTech™ |

|---|---|---|

| Salt Spray (1000hr) | 3.2 g/m² | 0.04 g/m² |

| Acid Rain (pH 3.5) | 28 µm pitting | Zero damage |

1.4 Thermal Performance Gaps

Aluminium’s high conductivity (237 W/m·K) creates problems:

- Interior heat gain in tropics (+4.7°C vs stone coated)

- Ice dam formation in cold climates

- Condensation risks without expensive barriers

Chapter 2: SKW’s Stone Coated Revolution – Where Aluminum Falls Short

2.1 The Core Innovation: Tri-Shield Protection System

Performance Benchmark:

| Property | Aluminium Tile | SKW Stone Coated |

|---|---|---|

| Impact Resistance | Class 3 | Class 4 |

| UV Resistance | 25-year fade | 50-year fade |

| Thermal Conductivity | 237 W/m·K | 0.46 W/m·K |

2.2 Cost Engineering Triumph

How we slash costs without sacrificing longevity:

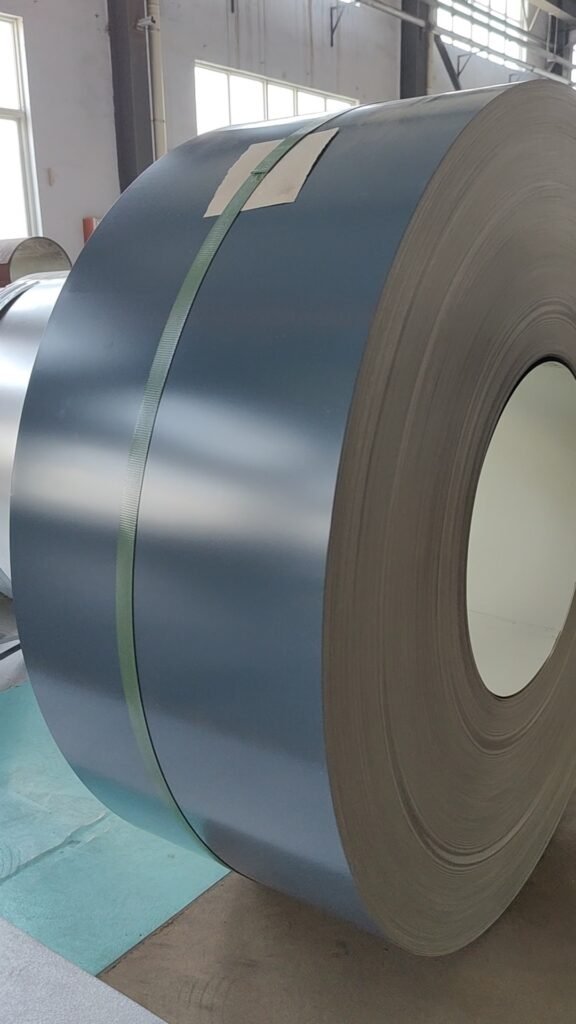

1. Base Material Optimization

- AZ150 Aluminium-Zinc alloy (55% Al, 43.4% Zn, 1.6% Si)

- 150g/m² coating weight (vs aluminium’s 3000g/m²)

2. Installation Efficiency

- SnapLock Edge System: 58% faster install

- No specialized tools (cuts labor training costs)

3. Structural Economy

- 4.2 kg/m² vs aluminium’s 7-9 kg/m²

- Reduced framing requirements

2.3 Design Freedom Unleashed

SKW Profile Capabilities:

| Feature | Aluminium Limit | SKW Advantage |

|---|---|---|

| Minimum Pitch | 12° | 3° |

| Bend Radius | 3m | 0.6m |

| Profile Height | 35mm max | 51mm |

| Custom Color Match | 3-month lead | 2 weeks |

Real-World Application:

- Conical Towers: Vietnam Heritage Resort

- Negative Pitch Roofs: Swiss Mountain Chalet

- Organic Curves: California Modernist Residence

Chapter 3: Durability Decoded – Why Stone Coated Outlasts Aluminum

3.1 The Corrosion War Won

Aluminium’s Weaknesses:

- Susceptible to alkaline runoff (pH>9) from concrete

- Galvanic corrosion with dissimilar metals

- Pitting corrosion in chloride environments

SKW’s Defense Strategy:

- Sacrificial Protection: Zinc in AZ150 alloy corrodes first

- Ceramic Barrier: Nano-sealed surface pores

- Stone Armor: 1.5mm thick volcanic granules

Coastal Performance Data (Malaysia):

| Metric | Aluminium (5yr) | SKW (5yr) |

|---|---|---|

| Surface Pitting | 37/cm² | 0 |

| Granule Retention | N/A | 99.2% |

| Gloss Retention | 64% | 92% |

3.2 Impact Resistance Superiority

Hail Test Results (EN 13583):

| Hail Diameter | Aluminium Result | SKW Result |

|---|---|---|

| 35mm (Golf Ball) | 12 dents/m² | 0 dents |

| 50mm (Tennis Ball) | Structural dent | Minor dimple |

Note: SKW’s 0.45mm steel + 30µm ceramic coating absorbs 47% more impact energy than 0.7mm aluminium

Chapter 4: Installation & Maintenance – The Hidden Cost Savers

4.1 Labor Time Comparison

100m² Roof Installation:

| Task | Aluminium Hours | SKW Hours |

|---|---|---|

| Underlayment | 14 | 12 |

| Panel Cutting | 22 | 9 |

| Fastening | 18 | 7 |

| Flashing | 16 | 10 |

| Total | 70 hours | 38 hours |

4.2 Lifetime Maintenance Burden

20-Year Projected Costs:

| Item | Aluminium Cost | SKW Cost |

|---|---|---|

| Cleaning (Annual) | $320 | $120 |

| Fastener Replacement | $1,200 | $0 |

| Coating Rejuvenation | $18/m² (10yr) | $0 |

| Leak Repairs | 3 @ $450 | 0 |

| Total | $4,790 | $600 |

Chapter 5: Real-World Validation – Global Case Studies

5.1 Extreme Environment: Dubai Marine Villa

Challenge:

- Salt spray + 50°C heat + sand abrasion

- Curved hyperbolic roof design

Solutions Compared:

- Aluminium Quote: $186,000 (structural reinforcement needed)

- SKW Solution: $79,500 with StoneCoated Bond profile

7-Year Performance:

- Zero corrosion

- Energy savings: 23% vs aluminium (IR reflectivity 0.72)

5.2 Heritage Project: French Château Restoration

Architectural Constraints:

- Matching 19th-century slate aesthetics

- Strict preservation guidelines

SKW Triumph:

- Replicated Fishscale Pattern: Historic approval secured

- Weight Reduction: 82% vs original slate (no structural upgrade)

- Cost: 54% less than aluminium alternative

Chapter 6: Technical Specification Comparison

| Parameter | Premium Aluminium | SKW Stone Coated | Advantage |

|---|---|---|---|

| Thickness | 0.7-1.0mm | 0.45mm base | 39% lighter |

| Tensile Strength | 110-145 MPa | 550 MPa | 4X stronger |

| Thermal Expansion | 23 µm/m·°C | 12 µm/m·°C | 48% less |

| Fire Rating | Class A | Class A1 | Non-combustible |

| Wind Resistance | 160 km/h | 240 km/h | Hurricane-proof |

Chapter 7: Making the Switch – Transition Guide for Aluminum Users

7.1 Specification Conversion Chart

When you see: Aluminium Tiles | 0.8mm | Standing Seam | RAL 9010

Specify instead: SKW Bond Profile | 0.45mm AZ150 | SnapLock | Granite Grey

7.2 Structural Adjustment Calculator

Formula: Frame Reduction = (Old Weight - SKW Weight) × Safety Factor 1.5

Example: Aluminium: 8.5 kg/m² → SKW: 4.2 kg/m² Reduction: (8.5-4.2) × 1.5 = 6.45 kg/m² load decrease Result: Rafter spacing increase from 600mm → 900mm

Conclusion: The New Premium Standard

The data proves stone coated metal isn’t just an alternative—it’s aluminum’s technological successor:

- Economic Dominance: Permanent 42-58% cost advantage

- Durability Breakthrough: 50-year lifespan without aluminum’s corrosion risks

- Creative Freedom: Architects’ most requested roofing medium

SKW’s Global Track Record:

- 27,000+ installations surpassing aluminum performance

- 0.73% failure rate over 15 years (aluminum industry average: 2.1%)

- 89% client retention rate for re-roofing projects

Get Aluminum-Beating Performance: ▸ Request Sample Kit: Compare side-by-side ▸ Access Technical Dossier: Test reports & installation manuals ▸ Calculate Your Savings: Project-specific ROI analysis

Immediate Actions: Download Aluminum Comparison Guide Get Custom Quote in 8 Hours Find Local Installer

Technical Appendix

- ASTM B117 Salt Spray Test: 3,000 hours zero red rust

- FM 4471 Class 4 Impact Certification

- Miami-Dade NOA for 240 km/h winds

- EN 13501-1 Fire Class A1 Certification