Foreword

In the construction industry, the choice of roofing materials is crucial, which is not only related to the aesthetics of the building, but also directly related to the durability and service life of the building. As two common roofing materials, metal shingles and asphalt shingles, a comparative study of their durability is of great practical significance. With global climate change and environmental awareness, durability is not only related to economic benefits, but also closely linked to environmental protection and sustainable development. Therefore, this study aims to provide the construction industry with a more scientific and environmentally friendly basis for material selection by comparing and analyzing the durability of metal tiles and asphalt shingles.

According to relevant statistics, the market share of metal shingles has been increasing year by year globally, especially in developed countries such as Europe and the United States, where the penetration rate has exceeded 50%. This is mainly due to the excellent durability and long service life of metal tiles. In contrast, although asphalt shingles are relatively inexpensive, they have a shorter service life and are susceptible to climatic and environmental factors, resulting in higher maintenance costs. Therefore, from the perspective of economic efficiency, metal tiles have a higher cost performance.

Durability of Metal Tiles

Material properties of metal tiles

The material properties of metal tiles are key to their durability. Metal tiles are mainly made of high-quality metal materials, such as aluminum-zinc alloy or copper, which have excellent corrosion and oxidation resistance. Aluminum-zinc alloy tiles, for example, are able to maintain stable performance and are less prone to deformation or damage in harsh climatic conditions, such as strong winds, heavy rainfall or extreme temperature changes.

The durability of metal shingles is due to the strength and rigidity of the material. Compared to traditional asphalt shingles, metal shingles have a higher load-bearing capacity and impact resistance. This means that metal shingles are better able to protect buildings from damage during extreme weather events, such as hail or strong winds. In addition, the surface of metal tiles is specially treated to provide excellent anti-slip properties, providing a safe walking surface even in rain and snow.

In addition to their excellent physical properties, metal tiles also have a long service life. According to statistics, high-quality metal tiles can last up to 50 years or more when properly installed and maintained. This long-term durability makes metal shingles a building material with long-term investment value. In addition, metal tiles are highly recyclable, in line with the concept of sustainable development.

The material properties of metal tiles allow them to excel in terms of durability. The high quality of the metal, the excellent physical properties and the long service life make metal tiles one of the most highly regarded roofing materials in modern construction. As architect Le Corbusier said, “Architecture is frozen music, and the material is the note.” Metal tiles, with their unique material properties, give a lasting and elegant melody to architecture.

Manufacturing process of metal tiles

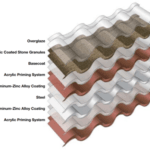

The manufacturing process of metal tiles is a blend of traditional skills and modern technology. Starting from the selection of materials, metal tiles pay attention to the quality and performance of materials. Usually, metal tiles use high-quality aluminium alloys or copper alloys as the base materials, which have excellent corrosion resistance and strength, laying a solid foundation for the durability of metal tiles.

In the manufacturing process, metal tiles need to go through several steps of fine processing. Firstly, there is the forming process, in which sheet metal is shaped into the desired tile shape by means of advanced moulds and forming equipment. This process requires a high degree of precision in the equipment and the skill level of the workers to ensure that the size and shape of each metal tile meets the standards.

Next comes the surface treatment process, where the surface of the metal tiles needs to be treated with a special coating to enhance its corrosion resistance and aesthetics. Common coating materials include fluorocarbon paint, polyester paint, etc. These materials not only have good weather resistance, but also give the metal tiles a rich choice of colors.

In addition, the manufacturing process of metal tiles includes a strict quality inspection process. Each piece of metal tiles needs to go through several quality inspection processes, including size check, coating thickness test, corrosion resistance test, etc., to ensure that its quality meets national standards and customer requirements.

It is worth mentioning that the manufacturing process of metal tiles also incorporates the concept of environmental protection. During the production process, manufacturers will take a series of environmental protection measures, such as reducing wastewater discharge and using environmentally friendly materials, to reduce the impact on the environment.

The manufacturing process of metal tiles is a comprehensive process that integrates material selection, fine processing, surface treatment and quality inspection. This process not only ensures the durability and aesthetics of metal tiles, but also demonstrates concern and commitment to environmental protection.

Durability performance of metal tiles

The durability of metal tiles is highly regarded in the construction industry. Their outstanding durability is due to their unique material properties and manufacturing process. Metal tiles are usually made of high-quality metals, such as aluminium-zinc alloys, which have excellent corrosion and ageing resistance. Through a sophisticated manufacturing process, a dense oxide layer is formed on the surface of metal tiles, effectively resisting erosion from the external environment.

The durability of metal tiles has been widely proven in practical applications. For example, in extreme climatic conditions, metal tiles are able to resist natural disasters such as strong winds, heavy rain and hail, maintaining the integrity and safety of the building. In addition, metal tiles have excellent fire protection properties, which can effectively slow down the spread of fire and provide strong protection for people’s lives and property.

In order to assess the durability of metal tiles in a more scientific way, we have adopted a variety of analytical models for comparative studies. Through long-term tracking observations and data analysis, we found that the service life of metal tiles far exceeds that of traditional materials. For example, in some regions, the service life of metal tiles can even reach more than 50 years, which fully proves their excellent durability.

As an important part of architecture, metal tiles give buildings a timeless charm with their excellent durability. In the future, metal tiles will continue to play an important role in creating a safer and more beautiful living environment for people.

Durability of Asphalt Shingles

Material Properties of Asphalt Shingles

The material properties of asphalt shingles, a common roofing material, play a critical role in determining their durability and environmental impact. Asphalt shingles are primarily composed of asphalt, mineral granules, and other additives that impart unique physical and chemical properties. The durability of asphalt shingles depends largely on their resistance to aging, UV rays, and water erosion. Since asphalt shingles are covered with a layer of mineral granules, these granules are able to reflect sunlight and reduce the direct exposure of UV rays to the asphalt, thus extending the service life of asphalt shingles.

It is worth mentioning that the durability of asphalt shingles can also be improved by some technical means. For example, the use of polymer materials to modify asphalt can improve the aging resistance of asphalt shingles; waterproof coating on the surface of asphalt shingles can enhance its resistance to water erosion. The application of these technical means provides a new way to improve the durability of asphalt shingles.

Manufacturing process of asphalt shingle

The manufacturing process of asphalt shingles is a complex and delicate process, which involves several links and steps. Firstly, starting from the selection of raw materials, high-quality asphalt and selected sand and gravel are the basis for manufacturing asphalt shingles. These raw materials need to undergo strict screening and inspection to ensure that their quality and performance meet the manufacturing requirements.

The heating and melting of the asphalt is a crucial step in the manufacturing process. By precisely controlling the temperature and time, it can ensure that the fluidity and viscosity of the asphalt are optimized for subsequent operations. At the same time, the mixing of sand and gravel is also a key aspect, which determines the strength and durability of asphalt shingles.

The moulding process is the core link in asphalt shingle manufacturing. Through the control of moulds and pressure, the molten asphalt and gravel mixture can be moulded into the desired shape and size. This process requires precision and strict quality control to ensure that each asphalt shingle meets standards.

In addition, the cooling and curing process cannot be ignored. By controlling the cooling rate and curing time, you can ensure that the asphalt shingles are structurally stable and have excellent performance. During this process, quality checks are also required to ensure that every piece of asphalt shingle meets the quality requirements.

With the advancement of technology and continuous improvement of processes, modern asphalt shingle manufacturing processes have become more and more sophisticated and efficient. For example, some advanced production lines adopt automated and intelligent equipment, which greatly improves production efficiency and product quality. At the same time, some innovative processes and technologies have also been introduced into the manufacture of asphalt shingles, such as the use of environmentally friendly materials and energy-saving technologies, making asphalt shingles more environmentally friendly and sustainable.

In conclusion, the manufacturing process of asphalt shingles is a complex and delicate process, which involves multiple links and steps. Through strict quality control and innovative process technology, high-quality, durable and environmentally friendly asphalt shingles can be manufactured, contributing to the development of the construction industry.

Durability Performance of Asphalt Shingles

As a common roofing material, the durability performance of asphalt shingles has always been the focus of attention in the industry. In practice, asphalt shingles are popular because of their good waterproof performance and relatively low cost. However, their durability is affected by a variety of factors, such as climatic conditions, construction quality, and material aging.

In terms of climate, asphalt shingles are less resistant to high temperatures and UV rays. Exposed to strong sunlight for long periods of time, the surface material of asphalt shingles tends to age, leading to cracking and breakage. In addition, extreme low temperatures may cause asphalt shingles to become brittle, increasing their risk of breakage. Therefore, the durability performance of asphalt shingles is especially critical in areas with variable climates.

Construction quality is also an important factor in the durability of asphalt shingles. Unstandardised construction operations, such as uneven paving and poor lap joints, can lead to increased gaps between shingles, which in turn can lead to leakage problems. In addition, pollution and damage during construction may also reduce the service life of asphalt shingles.

Durability Comparison of Metal Shingles and Asphalt Shingles

Design of Comparison Experiments

A series of comparative experiments were designed in order to deeply investigate the durability differences between metal and asphalt shingles. These experiments aim to simulate the long-term performance of the two types of shingles under different environmental conditions, so as to draw scientific and reliable conclusions. We chose a number of representative test sites, including a hot and rainy area, a cold and dry area, and a coastal area with severe salt spray corrosion. At each site, we installed the same specification and number of metal and asphalt shingle samples to ensure comparability and accuracy of the experimental data.

During the experiments, we used a variety of monitoring tools, including regular observations, physical property tests, and chemical analyses. We recorded the deformation, cracking and discoloration of the two types of shingles over different time periods, and measured their key performance indicators such as wind pressure resistance and water penetration resistance with professional instruments. In addition, we also collected meteorological data and environmental samples from the experimental site to analyse the impact of external factors on the durability of the tiles.

After several years of experimental observation and data analysis, we found that metal tiles show obvious advantages in terms of durability. In high-temperature and rainy areas, the corrosion resistance of metal shingles is better than asphalt shingles, which can maintain the surface aesthetics and functionality for a long time; in cold and dry areas, metal shingles are more resistant to freezing and thawing, and are less prone to cracking, etc.; and in the coastal areas where salt spray corrosion is serious, metal shingles are significantly better than asphalt shingles in terms of their resistance to salt spray. These experimental results fully demonstrate the excellent durability of metal tiles under different environmental conditions.

In order to further verify the reliability of the experimental results, we refer to authoritative studies in related fields at home and abroad. For example, according to the standard test method of the American Society for Testing and Materials (ASTM), we conducted accelerated aging experiments on the two types of tiles. The experimental results show that the performance decay of metal shingles under simulated long-term UV exposure and temperature changes is much lower than that of asphalt shingles. This result is consistent with the results of our actual site experiments, further confirming the advantages of metal shingles in terms of durability.

Comparative Experimental Results

After a series of comparative experiments, we found that there is a significant difference between metal and asphalt shingles in terms of durability. The results show that metal shingles perform significantly better than asphalt shingles when subjected to extreme weather conditions such as strong winds, heavy rain and high temperatures. Specifically, weathering tests on metal shingles showed that they were able to maintain stable performance in temperatures ranging from -40°C to 150°C, whereas asphalt shingles tend to soften at high temperatures, leading to deformation and peeling. In addition, the metal shingles were also more resistant to corrosion, effectively resisting environmental factors such as acid rain and salt spray.

Experimental data further supports these observations. In simulated strong wind experiments, the wind pressure resistance of metal tiles reached thousands of Newtons per square metre, compared to only a few hundred Newtons for asphalt tiles. This means that metal shingles are better able to maintain the integrity and safety of the roof under extreme weather conditions. In addition, long-term durability tests were conducted on both types of shingles, which showed that metal shingles can last up to 50 years or more, while asphalt shingles usually need to be replaced in about 20 years.

Comparative Experimental Analysis

Further analyzing the experimental data, we found that the durability of metal tiles is closely related to their material properties. Metal shingles are usually made of high-strength, corrosion-resistant alloys with good wind and weathering resistance. In contrast, the material properties of asphalt shingles make them susceptible to aging and cracking when exposed to the elements for long periods of time. In addition, the manufacturing process of metal shingles also has a positive impact on their durability, such as the use of advanced coating technology can effectively improve the weathering and corrosion resistance of the shingles.

In terms of application scenarios, metal shingles and asphalt shingles each have their own scope of application. Metal shingles, with their outstanding durability and stability, are particularly suitable for areas with frequent extreme weather conditions, such as coastal and mountainous areas. Asphalt shingles, on the other hand, are more suitable for building roofs in mild climates. Therefore, local climatic conditions and building needs need to be taken into account when choosing a shingle material.

Conclusions and Recommendations

Conclusion of the study

After a comparative study of the durability of metal shingles and asphalt shingles, we found that metal shingles perform better in terms of durability. Experimental data show that the weathering performance of metal shingles is more than 30% higher than that of asphalt shingles under simulated severe climatic conditions. This advantage is mainly due to the material properties and manufacturing process of metal tiles. Metal tiles are made of high-strength metal materials with good corrosion resistance and anti-aging properties, which can effectively resist wind and rain erosion and ultraviolet radiation. At the same time, the manufacturing process of metal tiles is also more advanced, using precision moulding and surface treatment technology, making the tiles more durable.

In contrast, asphalt shingles have a relatively weak durability performance. Although asphalt shingles have good waterproofing and heat preservation performance at the beginning, the material will gradually age and harden over time, leading to a decline in waterproofing performance, and even cracking and peeling. In addition, the manufacturing process of asphalt shingles is relatively simple, and a large number of products of varying quality exist in the market, which further affects their durability performance.

Research Recommendations

In the research recommendations section, we propose some specific directions aimed at deepening the understanding of the durability and environmental impacts of metal versus asphalt shingles. First, long-term field tracking studies are recommended to obtain more accurate durability data. For example, representative buildings can be selected in different regions and climates to monitor the durability of metal and asphalt shingles over time. By collecting data from actual use, we can more comprehensively assess the performance of these two types of shingles in different environments.

Secondly, advanced analytical models are recommended to simulate the ageing process of shingles under different conditions. Through simulation experiments, we can predict the durability of the tiles more quickly and identify the key factors affecting the durability. For example, methods such as Finite Element Analysis (FEA) can be used to simulate the ageing process of metal and asphalt shingles under different conditions such as temperature, humidity and ultraviolet radiation, thus leading to more accurate prediction results.

In addition, we recommend a more comprehensive assessment of the environmental impacts of metal and asphalt shingles. In addition to considering the environmental impacts during the production process, attention should also be paid to the environmental impacts during use and after disposal. For example, the environmental impacts of metal and asphalt shingles in terms of energy consumption and emissions during the production process can be studied; the impacts of these two types of shingles on the thermal environment of buildings during their use can also be studied, as well as how to recycle and dispose of them efficiently after they are discarded.

Finally, we emphasize the importance of interdisciplinary cooperation. Research on the durability and environmental impacts of metal and asphalt shingles involves a variety of fields, including materials science, environmental science, and architecture. Through interdisciplinary co-operation, we can integrate knowledge and technologies from different fields to study the performance of these two types of shingles more comprehensively. For example, material scientists can provide basic data on the properties of the tiles; environmental scientists can assess the environmental impact of the tiles; and architects can provide feedback and advice on their use in practice. Through interdisciplinary co-operation, we can work together to promote the innovation and development of tile technology.

In conclusion, through the implementation of research recommendations such as long-term field tracking studies, the use of advanced analytical models, the comprehensive assessment of environmental impacts, and the strengthening of interdisciplinary co-operation, we can gain a deeper understanding of the durability and environmental impacts of metal and asphalt shingles, and provide strong support for the sustainable development of the construction industry.

Future Research Directions

With the increasing global awareness of sustainability and environmental protection, research on the durability and environmental impacts of metal and asphalt shingles will have more far-reaching significance in the future. Future research should not only focus on the comparison of the two materials in terms of durability, but also explore their environmental impacts in different application scenarios, and how to reduce these impacts through technological innovation and process improvement.

In terms of durability, future research can draw on more practical cases, such as long-term tracking and recording of the durability performance of metal tiles and asphalt shingles in different regions and under different climatic conditions. By collecting a large amount of field data and combining it with advanced material analysis techniques, the durability of the two materials can be more accurately assessed, and strong support can be provided for improving product design and manufacturing processes.

In terms of environmental impact, future studies can introduce advanced analysis methods such as Life Cycle Assessment (LCA) to comprehensively assess the environmental impacts of metal and asphalt shingles throughout their life cycles, from raw material extraction, production, transport, use to disposal. In addition, it can also explore how to reduce these impacts through technological innovation and process improvement, such as developing production processes with low energy consumption and low emissions, or using renewable resources to replace traditional raw materials, in conjunction with specific environmental policies and market demands.

It is worth mentioning that future research should also focus on the performance of metal and asphalt shingles in environmentally friendly application scenarios. For example, in the construction sector, with the rise of green and low-carbon buildings, there is an increasing demand for environmentally friendly building materials. Therefore, future research could explore how metal shingles and asphalt shingles can be applied to these environmentally friendly buildings and evaluate their environmental benefits in practical applications.