1. Introduction: The Global Shift Toward Climate-Resilient Architecture

The twenty-first century has ushered in an era defined by unprecedented environmental challenges, with the escalating frequency and intensity of extreme weather events becoming a global concern. From devastating hurricanes and prolonged heatwaves to severe blizzards and torrential rains, these climatic shifts are placing immense pressure on infrastructure worldwide, particularly on the most vulnerable component of any building: its roof. Traditional roofing materials, once deemed adequate, are increasingly proving insufficient in the face of these modern climate scenarios. Asphalt shingles succumb to cracking and granule loss under extreme UV exposure and hail, clay tiles shatter with freeze-thaw cycles, and conventional metal roofs can buckle under hurricane-force winds or corrode rapidly in coastal environments.

This pressing need for enhanced resilience has catalyzed a fundamental shift in architectural and construction paradigms, driving a demand for climate-resilient building solutions. Property owners, developers, and architects are no longer merely seeking shelter; they are actively pursuing systems that offer robust, long-term protection against the elements, coupled with sustainable performance and aesthetic appeal. In this critical juncture, stone coated metal roofing has emerged not just as an alternative, but as a leading engineering solution designed to future-proof structures against the vagaries of a changing climate. Its unique fusion of steel’s inherent strength with the protective and aesthetic qualities of natural stone positions it as a superior choice for durable architecture in the 21st century.

At the forefront of this innovative wave is SKW Roof, a distinguished Chinese manufacturer with 16 years of specialized experience in the foreign trade export industry. With a proven track record of delivering high-quality, innovative stone coated metal roofing solutions to projects across more than 80 countries, SKW Roof has consistently demonstrated its commitment to engineering excellence. Our mission extends beyond mere manufacturing; it is about protecting structures and investments globally, providing peace of mind through roofing systems meticulously designed and rigorously tested to perform under the most demanding environmental conditions imaginable. This article will delve into the science and performance of stone coated metal roofing, particularly highlighting how it stands as the definitive answer to the global call for climate-resilient architecture.

2. Material Science: The Anatomy of a Climate-Defying Tile

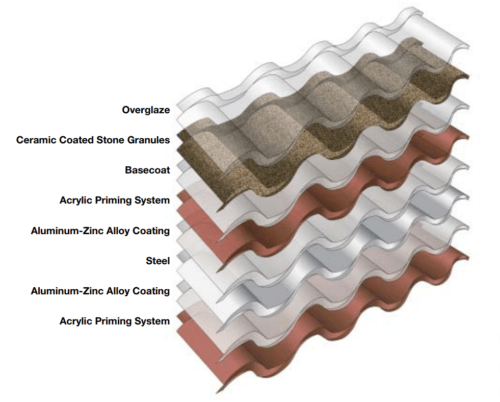

The exceptional performance of stone coated metal roofing in extreme environments is not accidental; it is the direct result of sophisticated material science and precision engineering. At its core, this roofing system is a multi-layered composite, meticulously designed to leverage the strengths of each component while mitigating their individual weaknesses. Understanding this anatomy is crucial to appreciating its climate-defying capabilities.

Each stone coated metal tile begins with a robust steel base, typically composed of Galvalume® (a proprietary alloy of aluminum, zinc, and silicon). This Galvalume® steel is chosen for its superior corrosion resistance compared to galvanized steel, offering a self-healing property where the zinc and aluminum components protect exposed edges. This base provides the structural integrity, making the tiles lightweight yet incredibly strong, capable of withstanding significant impact and uplift forces. The gauge of this steel (e.g., 26-gauge, 24-gauge) is a critical factor, directly influencing the tile’s rigidity and resistance to deformation under stress.

Adhered to this steel base is a series of protective coatings. First, an acrylic primer is applied to ensure optimal adhesion for subsequent layers. This is followed by the application of finely crushed natural stone granules, which are the visible surface of the tile. These granules, often sourced from volcanic rock, are not merely decorative. They serve multiple critical functions:

•UV Protection: The stone granules act as a natural barrier against the sun’s harsh ultraviolet rays, preventing the degradation of the underlying acrylic and steel, which is a common failure point for many roofing materials.

•Physical Impact Resistance: They provide an additional layer of defense against hail, falling debris, and foot traffic, absorbing impact energy and preventing dents or punctures to the steel core.

•Noise Reduction: The textured surface significantly dampens the sound of rain and hail, offering superior acoustic performance compared to bare metal roofs.

•Aesthetic Versatility: The natural stone allows for a vast array of colors and profiles, mimicking traditional roofing styles like clay tiles, wood shakes, or asphalt shingles, thereby offering architectural flexibility without compromising performance.

SKW Innovation: A key differentiator in the quality and longevity of stone coated metal roofing lies in the specialized acrylic resins used in the coating process. SKW Roof employs advanced acrylic formulations that are specifically engineered for UV stabilization. These resins encapsulate the stone granules, ensuring their long-term adhesion and preventing color fading or granule detachment, even under prolonged exposure to intense solar radiation. This proprietary blend enhances the roof’s aesthetic appeal over decades and maintains its protective properties.

Why “Source Factory” quality control matters: As a direct-from-source manufacturer with 16 years of export experience, SKW Roof emphasizes stringent quality control at every stage. This includes:

•Steel Gauge Consistency: Ensuring uniform thickness of the Galvalume® steel base across all production batches, which is vital for consistent structural performance.

•Stone Granule Adhesion: Employing advanced electrostatic application techniques and high-quality acrylic binders to guarantee maximum granule embedment and prevent premature shedding.

•Coating Thickness Uniformity: Precisely controlling the thickness of each protective layer to ensure comprehensive coverage and optimal performance characteristics.

This meticulous attention to material science and manufacturing precision ensures that every SKW stone coated metal roof tile is not just a component, but a climate-defying marvel, ready to perform reliably in the most challenging global environments.

3. The Tropical Challenge: Heat, Humidity, and Heavy Rain

Tropical climates, characterized by intense heat, pervasive humidity, and frequent torrential downpours, present a unique set of challenges for roofing materials. In regions spanning Southeast Asia, parts of Africa, and Latin America, a roof must not only provide shelter but also actively contribute to thermal comfort, resist moisture-related degradation, and withstand the sheer force of heavy rainfall. Stone coated metal roofing, particularly when engineered with these specific conditions in mind, offers superior performance compared to many conventional options.

Thermal Performance: Breaking the “Heat Island Effect”

One of the primary concerns in tropical environments is heat management. Dark-colored roofs, especially those made from asphalt or traditional metal, tend to absorb a significant amount of solar radiation, contributing to the “heat island effect” and driving up indoor temperatures. Stone coated metal roofs address this through several mechanisms:

•Reflective Stone Granules: The natural stone granules, particularly lighter shades, possess inherent reflective properties. They scatter a large portion of the sun’s infrared and ultraviolet radiation, preventing heat absorption into the roof structure.

•Air Gap Ventilation: Many stone coated metal roofing systems are installed over a batten system, creating a crucial air gap between the roof deck and the tiles. This air gap facilitates continuous airflow, allowing superheated air to escape, thereby reducing heat transfer into the attic space. Studies have shown that this passive ventilation can significantly lower attic temperatures, leading to a reduction in cooling loads and energy consumption by up to 25% in some cases.

•Low Thermal Mass: Unlike heavy concrete or clay tiles that retain heat for extended periods, the relatively low thermal mass of stone coated metal tiles means they cool down faster once the sun sets, contributing to more comfortable nighttime temperatures.

Moisture Management: Preventing Mold and Algae Growth

Pervasive humidity in tropical regions creates an ideal breeding ground for mold, mildew, and algae, which can rapidly degrade the appearance and integrity of many roofing materials. Asphalt shingles, for instance, are particularly susceptible to algae streaking. Stone coated metal roofs, however, are inherently resistant to these biological growths:

•Non-Porous Surface: The sealed stone granule surface is non-porous, preventing moisture absorption that would otherwise foster microbial growth.

•Anti-Algae Treatments: Many high-quality stone coated metal tiles, including those from SKW Roof, incorporate anti-algae treatments into their acrylic overglaze. These treatments actively inhibit the growth of algae and moss, maintaining the roof’s aesthetic appeal and preventing the need for frequent, costly cleaning.

•Rapid Drying: The material’s composition and installation method (often with an air gap) allow for rapid drying after rainfall, further reducing the conditions conducive to biological proliferation.

Rain Noise Reduction: The Acoustic Science of Stone Coating

While traditional corrugated metal roofs are notorious for their loud noise during heavy rain, stone coated metal roofs offer a significantly quieter alternative. The textured surface of the stone granules, combined with the multi-layered construction, effectively dampens acoustic vibrations. The granules disrupt the impact of raindrops, scattering the sound waves and preventing the resonant drumming effect common with bare metal. This acoustic advantage is particularly valued in residential and commercial applications in tropical regions, where sudden, intense downpours are a daily occurrence.

Case Study Snippet: Performance in the Philippines and Malaysia

In the bustling urban centers and serene coastal towns of the Philippines and Malaysia, where tropical storms are a regular feature, SKW Roof’s stone coated metal tiles have demonstrated exceptional performance. Projects ranging from residential complexes in Cebu to commercial buildings in Kuala Lumpur have benefited from the superior thermal regulation, moisture resistance, and acoustic comfort provided by these advanced roofing systems. The ability to withstand prolonged periods of high humidity and intense rainfall without degradation or significant maintenance has made them a preferred choice for architects and developers seeking long-term, reliable solutions in these challenging climates.

4. Coastal & High-Salinity Environments: Defeating the “Salt Monster”

Coastal regions, with their picturesque views and refreshing sea breezes, present one of the most aggressive environments for building materials, particularly roofing. The constant exposure to salt-laden air, often carried inland by prevailing winds, leads to a phenomenon known as salt spray corrosion. This “salt monster” relentlessly attacks metal surfaces, accelerating degradation and significantly shortening the lifespan of conventional roofing systems. For stone coated metal roofs, while the Galvalume® steel core offers inherent protection, continuous innovation is crucial to combat this specific challenge.

The Chemistry of Salt Spray Corrosion on Metal Roofs

Salt spray corrosion is an electrochemical process. Airborne salt particles (primarily sodium chloride) deposit on metal surfaces, where they absorb moisture, forming a highly corrosive electrolyte. This electrolyte facilitates the rapid oxidation of the metal, leading to rust and material loss. For steel, even with a protective coating like Galvalume®, microscopic imperfections or cut edges can become initiation points for corrosion. Over time, this can compromise the structural integrity of the roof, leading to leaks, aesthetic degradation, and costly premature replacement.

SKW Technology: Deep Dive into the 6,000-hour Salt Spray Resistance (Nano-Sealed Steel Core)

Recognizing the critical need for enhanced corrosion protection in coastal and high-salinity environments, SKW Roof has developed a groundbreaking solution: the Nano-Sealed Steel Core technology. This innovation directly addresses the vulnerability of traditional Galvalume® steel, particularly at cut edges where the protective zinc-aluminum layer can be compromised.

SKW’s Nano-Sealed Steel Core incorporates a 20µm ceramic layer applied via an advanced atmospheric plasma deposition process. This ultra-thin, yet incredibly dense, ceramic layer acts as an impermeable barrier, sealing the steel core and preventing corrosive agents from reaching the metal substrate. The plasma deposition ensures a uniform, defect-free coating that adheres molecularly to the Galvalume®.

Independent testing has rigorously validated the efficacy of this technology. SKW’s Nano-Sealed Steel Core has achieved an impressive 6,000 hours of salt spray resistance in accordance with ASTM B117 standards. This performance significantly surpasses the industry average for standard Galvalume® (typically around 1,200 hours) and even exceeds the requirements for many marine-grade materials. Furthermore, it boasts a 98.7% efficiency in edge corrosion protection, a critical factor given that edge corrosion is a common failure point for metal roofing in harsh environments.

Comparative Analysis: SKW vs. Standard Galvalume in Coastal Zones

To illustrate the profound impact of the Nano-Sealed Steel Core, consider the following comparative data for metal roofing installed within 5km of the ocean:

| Feature | Standard Galvalume® Steel Core | SKW Nano-Sealed Steel Core |

| Corrosion Resistance (ASTM B117 Salt Spray) | ~1,200 hours | 6,000+ hours |

| Edge Corrosion Protection Efficiency | ~70-80% | 98.7% |

| Expected Lifespan in Coastal Areas | 15-25 years | 40-50+ years |

| Maintenance Frequency (Corrosion-related) | Moderate (annual inspection for rust) | Low (periodic cleaning) |

| Warranty in Coastal Zones | Often limited or voided | Full 50-year transferable warranty |

This data unequivocally demonstrates that for projects in coastal or high-salinity environments, the investment in SKW’s Nano-Sealed Steel Core technology translates into significantly extended lifespan, reduced maintenance, and superior long-term performance. It provides architects and developers with a reliable solution that can withstand the most corrosive atmospheric conditions.

Maintenance Tips for Coastal Property Owners

Even with advanced protection like the Nano-Sealed Steel Core, proper maintenance can further extend the life and appearance of a stone coated metal roof in coastal areas:

•Regular Rinsing: Periodically rinse the roof with fresh water to remove accumulated salt deposits. This is especially important after prolonged dry spells or strong winds.

•Inspect for Debris: Remove any organic debris (leaves, branches) that can trap moisture and salt, leading to localized corrosion.

•Professional Inspection: Schedule annual professional inspections to identify and address any potential issues early, ensuring the roof’s continued optimal performance.

5. Hurricane & High-Wind Zones: The Physics of Uplift Resistance

Regions prone to hurricanes, typhoons, and other high-wind events demand roofing solutions that can withstand immense aerodynamic forces. The failure of a roof during such events can lead to catastrophic structural damage, rendering buildings uninhabitable and posing significant safety risks. Stone coated metal roofing, particularly when installed with advanced fastening systems, offers exceptional resistance to wind uplift, making it a preferred choice for these vulnerable areas.

Understanding Wind Uplift Forces and the “Peel Effect”

Wind flowing over a roof creates both positive and negative pressures. Positive pressure pushes down on the windward side, while negative pressure (suction) lifts on the leeward side and at the edges. This negative pressure is the primary cause of roof failure in high winds, often leading to the “peel effect” where roofing materials are progressively stripped away from the structure. The shape of the roof, its height, and the surrounding terrain all influence the magnitude of these forces. Traditional roofing materials like asphalt shingles, which rely on adhesive strips, are particularly susceptible to this uplift.

HurricaneLock™ System: The Engineering Behind Interlocking Panels

SKW Roof has engineered the HurricaneLock™ Installation System specifically to counteract these destructive wind uplift forces. This system goes beyond mere surface adhesion, creating a robust, interconnected roofing envelope that acts as a single, unified shield against extreme winds. The core principles of the HurricaneLock™ system include:

•Interlocking Panel Design: Unlike traditional shingles, SKW’s stone coated metal tiles feature an advanced interlocking design. Each tile mechanically fastens to the roof deck and interlocks with adjacent tiles on all four sides. This creates a continuous, rigid surface that distributes wind loads evenly across the entire roof, preventing individual tiles from peeling off.

•Concealed Fastening: The fasteners are hidden beneath the overlapping tiles, protecting them from direct exposure to wind, rain, and UV degradation. This not only enhances the roof’s aesthetic appeal but also ensures the long-term integrity of the fastening points.

•Reinforced Batten System: The tiles are typically installed over a robust batten system, which provides an additional layer of structural support and creates the crucial air gap for ventilation. The battens themselves are securely fastened to the roof trusses, anchoring the entire system to the building’s frame.

Certification Focus: Meeting Miami-Dade and International Wind Load Standards

For regions with the most stringent building codes, such as Florida’s Miami-Dade County, compliance with specific wind load standards is paramount. The HurricaneLock™ system has undergone rigorous testing to meet and exceed these requirements. It has earned the prestigious Miami-Dade County Notice of Approval (NOA), a certification recognized globally as the benchmark for hurricane resistance. This certification verifies the system’s ability to withstand sustained winds and gusts equivalent to Category 5 hurricanes, providing unparalleled peace of mind for property owners in high-risk zones.

Why Vertical vs. Horizontal Fastening Makes the Difference in Category 5 Storms

The orientation and method of fastening are critical in high-wind performance. Many traditional roofing systems rely on horizontal fastening, which can create weak points susceptible to uplift. The HurricaneLock™ system, however, utilizes a combination of vertical and multi-directional fastening points that distribute stress more effectively. This ensures that the entire roof system remains securely anchored, even when subjected to the extreme suction forces generated by Category 5 hurricanes. The strategic placement and type of fasteners (e.g., specialized screws designed for high shear and pull-out resistance) are integral to this superior performance, preventing the progressive failure often seen in less robust systems.

6. High-Altitude & Arctic Performance: Freeze-Thaw Resilience

While tropical and coastal environments pose significant challenges, high-altitude and arctic regions present their own unique set of extreme conditions for roofing materials. Here, the primary adversaries are intense cold, heavy snow loads, and the relentless freeze-thaw cycle. This cycle, where water repeatedly freezes, expands, and thaws within porous materials, is a leading cause of degradation in many traditional roofing options. Stone coated metal roofing, engineered for these extremes, offers superior resilience.

The Danger of Water Expansion in Porous Materials

Traditional roofing materials such as clay tiles, concrete tiles, and even some types of natural stone are inherently porous. When water penetrates these materials and subsequently freezes, it expands by approximately 9%. This expansion exerts immense pressure within the material’s pores and capillaries, leading to micro-cracks that propagate over time. Repeated freeze-thaw cycles cause these cracks to widen, eventually resulting in spalling, delamination, and complete structural failure of the roofing material. This process not only compromises the roof’s integrity but also creates pathways for water ingress, leading to further damage to the underlying structure.

CryoFlex™ Alloy: How SKW Tiles Remain Ductile at -60°C

SKW Roof has specifically addressed the challenges of extreme cold with innovations like its CryoFlex™ Alloy. This specialized steel base, combined with a unique coating formulation, ensures that SKW stone coated metal tiles maintain their ductility and structural integrity even at exceptionally low temperatures. Traditional metals can become brittle in extreme cold, making them susceptible to cracking under impact or thermal stress. The CryoFlex™ Alloy is engineered to resist this embrittlement, allowing the tiles to flex and adapt without fracturing, even when subjected to temperatures as low as -60°C.

This advanced material science has been rigorously tested and proven in some of the world’s harshest environments. For instance, in projects like the Arctic LNG Plant in Siberia, SKW Roof’s tiles demonstrated unwavering performance, enduring prolonged periods of sub-zero temperatures, heavy snow, and strong winds without any signs of material fatigue or degradation. This real-world application underscores the reliability of SKW’s solutions in high-cold regions.

Snow Load Management: The Friction of Stone Granules in Preventing Dangerous “Snow Slides”

Heavy snowfall is another significant concern in high-altitude and arctic regions. While metal roofs are excellent for shedding snow, a smooth metal surface can lead to sudden, dangerous

7. Sustainability & The Circular Economy

In an era increasingly defined by environmental consciousness and the imperative for sustainable practices, the choice of building materials carries significant ecological implications. Stone coated metal roofing stands out as a remarkably sustainable option, aligning well with the principles of a circular economy. Its environmental benefits extend beyond its manufacturing process to its entire lifecycle, offering a compelling case for eco-conscious construction.

100% Recyclability of Steel Cores

One of the most significant environmental advantages of stone coated metal roofing is the inherent recyclability of its steel core. Steel is one of the most recycled materials globally, and unlike many other roofing materials that end up in landfills, stone coated steel tiles can be 100% recycled at the end of their exceptionally long service life. This dramatically reduces landfill waste and conserves natural resources, as recycled steel requires significantly less energy to produce than virgin steel. SKW Roof is committed to sourcing steel from suppliers who adhere to responsible environmental practices, further enhancing the sustainability profile of our products.

Energy Savings: Reducing HVAC Load by up to 25%

The energy efficiency of stone coated metal roofs contributes directly to a reduction in a building’s carbon footprint. As discussed in the section on tropical climates, the reflective properties of the stone granules, combined with the potential for an air gap installation, significantly reduce heat transfer into the building. This leads to a lower demand for air conditioning in warmer climates and can also contribute to better insulation in colder climates, thereby reducing heating costs. Studies have indicated that buildings with energy-efficient roofing can see a reduction in HVAC (Heating, Ventilation, and Air Conditioning) energy consumption by up to 25%. This translates into substantial savings on utility bills for property owners and a measurable decrease in greenhouse gas emissions associated with energy production.

Longevity as the Ultimate Sustainability: Why a 50-Year Roof is Better for the Planet than Three 15-Year Roofs

Perhaps the most overlooked aspect of sustainability in roofing is longevity. A roofing material with a 50-year-plus lifespan, like stone coated metal, inherently reduces environmental impact simply by minimizing the frequency of replacement. Consider the lifecycle impact: manufacturing, transportation, installation, and disposal of three asphalt shingle roofs (each lasting 15-20 years) versus one stone coated metal roof over the same 50-60 year period. The cumulative energy, raw material consumption, and waste generation associated with multiple replacements far outweigh the initial impact of a single, long-lasting stone coated metal roof. By choosing a durable, long-life roofing solution, property owners make a significant contribution to resource conservation and waste reduction, embodying the true spirit of sustainable building practices.

8. Procurement Strategy for Professionals: Architect & Developer Guide

For architects, developers, and large-scale project managers, specifying and procuring roofing materials involves a complex interplay of performance requirements, aesthetic considerations, budget constraints, and logistical challenges. When considering stone coated metal roofing, particularly from an international source like SKW Roof, a strategic procurement approach is essential to ensure project success and maximize long-term value.

How to Specify Stone Coated Metal Roofing in Large-Scale Projects

Effective specification is the cornerstone of successful project execution. When integrating stone coated metal roofing into architectural designs, professionals should consider the following:

•Performance Metrics: Clearly define required performance standards, including wind uplift resistance (e.g., Miami-Dade NOA equivalent), fire rating (Class A), hail impact resistance, and corrosion resistance (e.g., salt spray hours for coastal projects). Specify SKW’s proprietary technologies like HurricaneLock™ and Nano-Sealed Steel Core where applicable.

•Material Composition: Detail the steel substrate (e.g., Galvalume® AZ150 or AZ200), stone granule type (e.g., natural volcanic rock), and acrylic coating specifications (e.g., UV-stabilized, anti-algae treated).

•Aesthetic & Profile: Specify the desired tile profile (e.g., classic tile, shingle, shake, Roman tile) and color palette. Request samples to ensure color consistency and texture match with architectural renderings.

•Installation System: Outline the preferred installation method, including batten system requirements, fastening details, and flashing specifications to ensure watertightness and structural integrity.

•Certifications & Standards: Insist on compliance with relevant international building codes (IBC), product standards (e.g., ASTM, CE, SONCAP), and quality management systems (ISO 9001).

Evaluating Factory Certifications (ISO, CE, SONCAP)

As a global supplier, SKW Roof understands the critical importance of international certifications in validating product quality and compliance. When evaluating potential manufacturers, look for:

•ISO 9001: This certification indicates a robust quality management system, ensuring consistent product quality from manufacturing to delivery.

•CE Marking: Essential for products entering the European market, CE marking signifies conformity with health, safety, and environmental protection standards.

•SONCAP (Standards Organization of Nigeria Conformity Assessment Programme): Crucial for projects in Nigeria and other African markets, SONCAP certification ensures products meet specific quality and safety standards for import.

•Product-Specific Certifications: Beyond general factory certifications, verify product-specific performance certifications, such as Miami-Dade NOA for wind resistance, Class A fire ratings, and extended salt spray test results.

The “Direct-from-Source” Advantage: Customization and Technical Support

Procuring directly from a source factory like SKW Roof offers distinct advantages for large-scale projects:

•Customization Capabilities: Direct access to manufacturing allows for greater flexibility in customization, including bespoke tile profiles, unique color formulations, and specific material compositions to meet project-specific requirements.

•Technical Expertise & Support: SKW Roof’s in-house engineering team provides direct technical support, from initial design consultation and material selection to installation guidance and post-project troubleshooting. This direct line to experts ensures that complex technical queries are addressed promptly and accurately.

•Cost Efficiency: Eliminating intermediaries can lead to more competitive pricing, particularly for bulk orders, without compromising on quality.

•Supply Chain Transparency: Direct procurement offers greater visibility and control over the manufacturing process and supply chain, ensuring timely delivery and adherence to quality standards.

By leveraging these advantages, architects and developers can confidently specify and procure stone coated metal roofing solutions that are perfectly tailored to their project’s needs, ensuring optimal performance and long-term value.

9. Conclusion: Future-Proofing Your Investment

The decision of selecting a roofing material is a long-term investment, one that profoundly impacts a building’s resilience, energy efficiency, and aesthetic appeal for decades. As the world grapples with increasingly unpredictable and extreme climatic conditions, the demand for roofing solutions that can truly withstand the test of time and nature has never been more critical. Stone coated metal roofing, with its unparalleled combination of durability, weather resistance, aesthetic versatility, and sustainable attributes, stands as the definitive answer to this evolving challenge.

Throughout this guide, we have explored the intricate material science, the rigorous engineering behind its climate-defying performance, and its proven efficacy across a spectrum of extreme environments—from the humid tropics and corrosive coastlines to hurricane-prone regions and the frigid arctic. Innovations such as SKW Roof’s Nano-Sealed Steel Core and HurricaneLock™ system are not merely incremental improvements; they represent a paradigm shift in roofing technology, offering property owners, architects, and developers a robust solution that is both high-performing and environmentally responsible.

Choosing stone coated metal roofing is an investment in peace of mind, a commitment to longevity, and a strategic move towards future-proofing your assets against the harshest elements. It is a testament to the power of advanced engineering meeting the demands of a changing world. For those seeking to safeguard their structures with a roofing system that offers superior protection, exceptional value, and enduring beauty, the path forward is clear.

Consult with SKW Roof’s Engineering Team: We invite you to connect with SKW Roof’s team of experts to discuss your specific project requirements. Leverage our 16 years of specialized experience and our commitment to delivering tailored, high-performance roofing solutions that meet the unique challenges of your climate and architectural vision. Let us help you build a future-proof roof that stands strong against any extreme.

10. Frequently Asked Questions (FAQ)

To further clarify the benefits and technical aspects of stone coated metal roofing, especially in extreme climates, here are answers to some frequently asked questions:

Q1: How does stone coated metal roofing perform in extreme heat and tropical climates?

A1: Stone coated metal roofs excel in extreme heat. The reflective properties of the stone granules, combined with an air gap created by batten installation, significantly reduce heat transfer into the building. This can lower indoor temperatures and reduce cooling costs by up to 25%. The non-porous surface and anti-algae treatments also prevent mold and algae growth common in humid tropical environments.

Q2: Is stone coated metal roofing resistant to salt spray corrosion in coastal areas?

A2: Yes, high-quality stone coated metal roofing, particularly SKW Roof’s products with Nano-Sealed Steel Core technology, offers exceptional resistance to salt spray corrosion. Our Nano-Sealed Steel Core features a 20µm ceramic layer applied via atmospheric plasma deposition, achieving over 6,000 hours of salt spray resistance (ASTM B117), far exceeding industry standards and ensuring durability in harsh coastal environments.