Introduction: The Silent Threat to Roof Integrity

Imagine this: after investing in a beautiful, durable stone-coated metal roof for your home or project, you begin to notice a disconcerting sight—fine granules of sand steadily detaching from the panels, collecting in gutters or scattering on the ground below. This phenomenon, known as “sanding” or granule loss, is more than just a cosmetic flaw. It is the first alarm bell, signaling a critical failure in the roof’s protective adhesive layer. As the granules fall, they expose the underlying metal substrate to the sun’s UV rays, extreme temperatures, and moisture, leading to accelerated corrosion, reduced energy efficiency, and a drastically shortened roof lifespan.

At SKW Roof, we understand that the longevity and performance of a stone-coated metal roof are only as strong as the bond that holds it together. As a leading stone-coated metal roof manufacturer from China, we have dedicated our expertise to eradicating this very issue. The secret doesn’t lie solely in the quality of the steel or the granules, but in the sophisticated, climate-tailored adhesive formula that fuses them into an inseparable, resilient shield. This article delves deep into the science behind adhesive failure, our proprietary approach to custom adhesive formulation, and how we guarantee a roof that won’t shed its protective skin, no matter where in the world it is installed.

1. Deconstructing the Problem: Why Do Roofs “Shed Sand”?

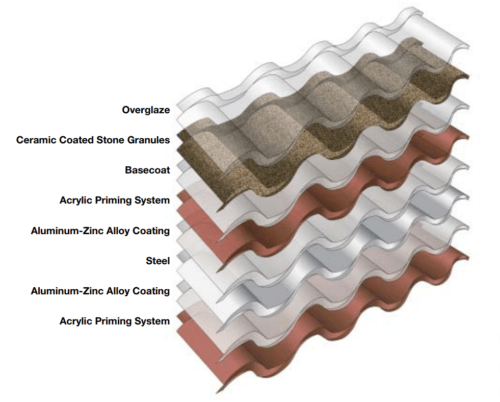

The stone-coated metal roof is a masterpiece of composite engineering. Its core structure typically consists of:

- Base Steel Substrate: Usually galvanized or Galvalume steel, offering structural strength and rust resistance.

- Adhesive Layer: The crucial, often overlooked intermediary. This thermosetting layer is applied to the metal and acts as the “glue.”

- Stone Granules: Natural crushed basalt or similar stones, embedded into the adhesive. They provide UV protection, color, texture, and fire resistance.

- Acrylic Protective Coating: A final transparent layer that enhances granule lock-in and adds initial weather resistance.

The failure point is invariably the adhesive layer. Here’s how it happens:

- The “Cost-Cutting” Culprit: Some manufacturers, in a bid to reduce costs, use inferior adhesive formulas with poor UV stability, thermal plasticity, or low bonding strength. An even more common shortcut is applying the adhesive layer too thinly. This thin layer cannot fully encapsulate the granules, leading to a weak, superficial bond.

- The Climate Assault: A roof is subjected to relentless environmental stress.

- Thermal Cycling: In regions with high diurnal temperature swings (e.g., deserts), the metal substrate expands and contracts daily. A rigid, low-quality adhesive cannot flex with this movement, causing micro-fractures that break the granule bond.

- Extreme Heat: In tropical or arid climates, sustained high temperatures (roof surfaces can exceed 70°C/158°F) can cause inferior adhesives to soften or become brittle, losing their grip.

- Bitter Cold: In arctic or alpine regions, adhesives must remain flexible down to -30°C (-22°F) or lower. Brittle adhesive will shatter under minor impact or stress.

- Impact Stress: During installation, installers walk on and nail the panels. Hailstorms also subject the roof to impact. A weak adhesive bond will cause granules to dislodge from these mechanical shocks—the “sanding down” effect during installation is a classic red flag.

- The Consequence: Once granule loss begins, it’s a degenerative process. The exposed adhesive layer degrades faster under UV exposure, leading to more granule loss. The exposed metal is vulnerable, and the roof’s warranty often becomes void.

2. The SKW Roof Solution: Precision Adhesive Engineering for Every Climate

We reject the one-size-fits-all approach. Our philosophy is that a roof destined for the humid, salty air of Florida requires a different adhesive chemistry than one bound for the dry, scorching heat of Saudi Arabia or the freeze-thaw cycles of Canada.

Our core commitment: We develop and apply a custom adhesive formula for every major climate zone and project requirement.

Our R&D process is meticulous:

- Climate Analysis: We start by analyzing your location’s specific climate data: average high/low temperatures, humidity ranges, UV index, and typical precipitation.

- Formula Selection & Customization: We have a library of proven, high-performance base formulas. Based on the analysis, our chemists adjust key components:

- Polymer Base: Selecting the right acrylic, modified asphalt, or hybrid polymer for flexibility and adhesion.

- Plasticizers & Modifiers: Adjusting types and quantities to set the perfect Glass Transition Temperature (Tg)—the point at which the adhesive transitions from brittle to flexible. A hot climate formula will have a higher Tg to resist softening; a cold climate formula will have a lower Tg to prevent brittleness.

- Cross-linking Agents: Enhancing the thermosetting properties to ensure the adhesive cures into a tough, insoluble network.

- UV Stabilizers & Antioxidants: Boosting resistance to solar degradation, crucial for sunny regions.

- Rigorous Laboratory Testing: Every batch and every custom formula undergoes brutal testing that simulates decades of wear in a short time.

- Weatherometer (QUV) Testing: Simulates years of UV exposure and condensation.

- Thermal Shock Cycling: Panels are rapidly moved between extreme heat and cold chambers to test adhesion under stress.

- Peel Strength Test: Measures the force required to pull granules from the coated metal, providing a quantifiable bond strength value.

- Flexibility Test (Mandrel Bend): The coated panel is bent around a rod at specified low temperatures to check for cracking or granule loss.

3. A World of Applications: Our Tailored Formulas in Action

- For Southeast Asia & Coastal Regions (High Heat, High Humidity, Salt):

- Challenge: Heat softens adhesive, humidity encourages microbial growth, salt accelerates corrosion.

- Our Formula: Uses a highly UV-resistant polymer base with antifungal additives. The adhesive is formulated to maintain high peel strength even at elevated temperatures and has enhanced corrosion-inhibiting properties.

- Client Case: A large resort project in Thailand required a roof to withstand constant 90%+ humidity and intense sun. Our custom formula passed 4000 hours of salt spray and QUV testing without significant granule loss.

- For the Middle East & Desert Climates (Extreme Dry Heat, UV Radiation, Dust Storms):

- Challenge: Extreme thermal cycling (hot days, cool nights) and powerful UV radiation break down materials.

- Our Formula: Focuses on exceptional thermal stability and UV blockers. The adhesive layer is applied at a controlled, optimal thickness to ensure full granule encapsulation and flexibility to accommodate metal expansion/contraction.

- Client Case: A villa developer in Dubai needed a roof that wouldn’t degrade in 50°C+ (122°F) heat. Our panels, with the climate-specific adhesive, showed no adhesive flow or granule loss in heat chamber tests at 120°C (248°F).

- For North America & Europe (Four Seasons, Freeze-Thaw, Hail):

- Challenge: Wide temperature range from summer heat to winter deep freeze. Ice dams and hail are common.

- Our Formula: Engineered for a wide operational temperature window. It remains flexible in deep cold to resist hail impact without shattering and stable in summer heat. It has excellent moisture resistance to handle freeze-thaw cycles.

- Client Case: A distributor in Canada needed a roof rated for severe hail (UL 2218 Class 4). Our adhesive’s impact resistance was crucial in ensuring the granule layer remained intact during testing, allowing the panels to achieve the top rating.

- For Specialized Architectures (Steep Slopes, Curved Roofs):

- Challenge: Panels on steep slopes experience higher gravitational pull on granules. Curved installations put continuous stress on the adhesive bond.

- Our Formula: We specify a high-tack, high-shear strength formula with even greater peel resistance to ensure granules stay locked in place over decades, regardless of the installation angle.

4. Beyond Adhesive: Our Holistic Manufacturing Excellence

While adhesive is the star, it performs in synergy with our entire manufacturing standard:

- Metal Preparation: We use a multi-stage cleaning and pretreatment process on our steel (AZ100 or higher Galvalume) to ensure a perfectly clean, reactive surface for the adhesive to bond to.

- Precise Application: Our automated roller-coating systems apply the adhesive at a strictly controlled and verified thickness—never thin to save cost. We ensure complete, uniform coverage.

- Granule Embedment: The stone granules are electrostatically and mechanically embedded while the adhesive is in a precise state of cure, ensuring they sink in for a deep, mechanical lock.

- Final Curing: The panels pass through a controlled curing oven that perfectly sets the adhesive into its final, tough state.

5. Questions to Ask Your Supplier: Your Shield Against “Sanding”

As an informed buyer, you must vet your supplier. Do not settle for vague promises. Ask these direct questions:

- “Do you adjust your adhesive formula for different climate zones, or do you use one universal formula?”

- “Can you provide technical data sheets for the adhesive, showing its peel strength, flexibility temperature range, and UV resistance ratings?”

- “What specific tests do you perform on finished panels to validate granule adhesion? Can I see the test reports (e.g., peel strength, QUV, thermal cycle)?”

- “What is your standard applied thickness for the adhesive layer, and how do you control it during production?”

- “Do you have case studies or performance warranties that specifically address granule adhesion failure?”

A reputable manufacturer like SKW Roof will have clear, confident answers and documentation ready.

Conclusion: Partner for a Roof That Truly Lasts

The integrity of a stone-coated metal roof is a complex equation where the adhesive is the most critical variable. Choosing a supplier who prioritizes advanced, customized adhesive technology is not a detail—it is the fundamental decision that determines whether your roof will be a durable asset or a deteriorating liability.

At SKW Roof, we combine the efficiency and scalability of being a Chinese source factory with the sophisticated engineering and quality ethos demanded by global markets. We don’t just sell roofs; we provide climate-optimized roofing systems backed by science, rigorous testing, and a commitment to transparency.

Visit our website at https://skwroof.com/ to explore our product range and connect with our technical team. Let us analyze your project’s climate and requirements, and we will demonstrate how our tailored adhesive technology delivers a roof that stands firm, granule by granule, for decades to come.