Market Application and Popularity of Metal Shingles and Asphalt Shingles

With the rapid development of the construction industry, the choice of roofing materials has become increasingly important. As two common roofing materials, metal shingles and asphalt shingles have gained wide application and popularity in the market. Metal shingles are gradually gaining popularity among architects and homeowners for their unique materials and beautiful appearance. According to statistics, the market share of metal tiles has been increasing year by year in recent years, especially in the field of high-end residential and commercial buildings. Asphalt shingles, on the other hand, with their affordable and easy-to-construct features, dominate in ordinary residential and civil buildings. However, as environmental awareness increases and the concept of sustainable development takes hold, metal shingles are gradually receiving more attention due to their recyclability and long lifespan.

Maintenance Cost Analysis of Metal Tiles

Material Costs: Purchasing Prices and Market Fluctuations for Metal Shingles

As a high-quality roofing material, the purchase price and market fluctuations of metal tiles have a significant impact on the cost of roof maintenance. The purchase price of metal tiles is affected by a variety of factors, including raw material prices, production processes, brand awareness, and market supply and demand. In the metal tile market, the price of different brands, specifications and quality of metal tiles varies greatly, so choosing the right brand of metal tiles is critical to controlling maintenance costs.

Market fluctuations have a direct impact on the purchase price of metal tiles. Supply and demand in the metal tile market, changes in raw material prices, and fluctuations in the global economic situation can all lead to fluctuations in metal tile prices. For example, when raw material prices rise, the cost of producing metal tiles increases, which in turn pushes up their purchase price. Conversely, when the market is oversupplied, the price of metal tiles may fall. Therefore, when purchasing metal tiles, you need to pay close attention to the market dynamics so that you can make timely purchases when the price is right.

In order to reduce the risks associated with the purchase price and market fluctuations of metal tiles, there are a number of strategies that can be adopted. First, establish long-term relationships with multiple suppliers to ensure stable supply when prices fluctuate. Second, pay attention to market dynamics and keep abreast of raw material prices, market supply and demand, so that you can purchase when the price is right. In addition, consider adopting centralised purchasing to reduce unit costs through bulk purchasing. All these strategies help to reduce the impact of the purchase price of metal tiles and market fluctuations on maintenance costs.

Installation Costs: Construction Difficulty and Labour Costs of Metal Tiles

In terms of installation costs, metal shingles have unique characteristics compared to asphalt shingles. Firstly, the construction difficulty of metal tiles is relatively high. Due to the material and structural design of metal tiles, the installation process requires higher precision and skills. Construction personnel need to be familiar with the characteristics of metal tiles and master the correct installation methods and techniques to ensure a tight connection between the tiles and waterproofing effect. Such difficult construction requirements often lead to longer installation times, which increase labour costs.

In addition, the installation of metal tiles requires specialised tools and equipment. For example, special clamps and sealing materials are required to ensure a tight connection between the tiles and prevent water leakage. The acquisition cost of these specialised tools and materials also adds to the installation cost.

However, despite the higher installation costs of metal shingles, their long-term benefits should not be overlooked. The durability and stability of metal tiles make them relatively low maintenance. According to research data, metal tiles typically have a lifespan of 50 years or more and are less susceptible to climate and environmental influences during use. This means that once the installation is complete, the maintenance cost of metal shingles will be much lower than that of other materials such as asphalt shingles.

Maintenance Costs: Durability and Long-Term Maintenance of Metal Shingles

The durability of metal shingles is a key factor in their importance in the analysis of roof maintenance costs. Compared to traditional asphalt shingles, metal shingles have a longer service life, which directly affects their long-term maintenance costs. According to research data, metal shingles have an average lifespan of more than 50 years, and high-quality shingles can last up to 70 years, which greatly exceeds the average lifespan of asphalt shingles, which is 20 to 30 years.

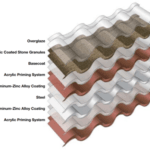

The durability of metal tiles is due to their material properties. Metal tiles are usually made from high-quality materials such as aluminum-zinc alloys, which have excellent corrosion and weather resistance. In addition, the surface of metal tiles is specially treated to protect against UV rays, chemicals and pollutants, thus maintaining their long-term beauty and functionality.

From the point of view of long-term maintenance costs, the advantages of metal tiles are even more obvious. Thanks to their long service life and outstanding durability, metal tiles are relatively low-maintenance. Throughout the lifespan of metal shingles, only a small number of repairs and maintenance tasks, such as regular cleaning and inspection of fasteners, may be required. In contrast, asphalt shingles require more frequent maintenance and replacement, which increases long-term repair costs.

Maintenance Cost Analysis of Asphalt Shingles

Material Costs: Purchase Price and Quality Differences in Asphalt Shingles

When discussing the purchase price and quality differences of asphalt shingles, we first need to understand the asphalt shingle products on the market and their price ranges. The price of asphalt shingles is affected by a variety of factors, including the cost of raw materials, production processes, brand awareness, and market demand. As a result, asphalt shingles of different brands, specifications, and quality can vary widely in purchase price.

Generally speaking, high-quality asphalt shingles tend to be made from better quality raw materials and advanced production processes, hence their relatively higher purchase price. These products typically have better durability, anti-aging properties and waterproofing, which can keep the roof in good condition for a long time and reduce the frequency of repairs and replacements. In contrast, lower-quality asphalt shingles may use cheaper raw materials and simpler manufacturing processes, resulting in a relatively low purchase price but correspondingly poorer service life and performance.

To illustrate the difference between the purchase price and quality of asphalt shingles more concretely, we can cite some real-life examples. For example, in the market, the purchase price of some well-known brands of asphalt shingle products may be higher than that of common brands due to their strict quality control and high-quality raw materials. However, these high-quality products tend to provide better waterproofing and longer service life, thus reducing the cost of long-term maintenance and replacement.

There are also a number of analytical models that we can use to further explore the purchase price and quality differences in asphalt shingles. For example, we can construct a cost-benefit analysis model that takes into account factors such as the procurement price, service life and maintenance cost of asphalt shingles, so as to assess the cost-effectiveness of different brands, specifications and quality of asphalt shingles in long-term use. Such an analysis can help us understand more comprehensively the differences in the purchase price and quality of asphalt shingles, and provide a basis for decision-making on the selection of suitable roofing materials.

Installation Costs: Asphalt Shingle Construction Cycle and Labour Costs

The construction cycle and labour cost of asphalt shingles are important factors that should not be ignored when assessing their maintenance cost. First, in terms of construction lead time, the installation of asphalt shingles usually takes longer compared to metal shingles. This is because the installation process of asphalt shingles is relatively complex, requiring more steps and meticulous manual work. For example, you need to make sure that the roofing substrate is level and dry before laying asphalt shingles, which may require additional time and preparation. Additionally, asphalt shingle installation needs to take into account weather factors, such as rainy or cold weather that may affect the construction schedule. As a result, a longer construction period means higher labour costs.

In terms of labour costs, asphalt shingle installation requires a professional construction team and skilled technical workers. As the installation process of asphalt shingles is cumbersome and requires workers to have a high level of skills and experience, the demand for skilled workers is also relatively high. This results in relatively high labour costs for asphalt shingle installation. Additionally, due to the long construction period, workers are required to be on site for longer periods of time, which also adds to the labour costs.

To illustrate this point more concretely, we can refer to some real-world examples. For example, according to a study on roof repair costs, the installation cost of asphalt shingles typically accounts for 30 to 40 per cent of the overall repair cost. This percentage is significantly higher than the cost of installing metal shingles. Additionally, because asphalt shingle installation requires more manual work, more mistakes and damage can occur during the construction process, which further increases repair costs.

In summary, the construction cycle and labour cost of asphalt shingles are factors that should not be ignored when assessing their repair cost. Longer construction cycles and higher labour costs make asphalt shingles relatively expensive to repair. Therefore, when choosing roofing materials, various factors, including material performance, environmental adaptability, and maintenance costs, need to be considered in order to make a more informed decision.

Maintenance Costs: Life and Replacement Cycles of Asphalt Shingles

The maintenance cost of asphalt shingles is closely related to their life expectancy and replacement cycles. Generally speaking, asphalt shingles have a lifespan of between 20 and 30 years, depending on their quality, the installation process, and the environment in which they are used. During this life cycle, regular maintenance and servicing are critical to extending the life of asphalt shingles. However, even with proper maintenance, asphalt shingles still need to be replaced at the end of their life.

Maintenance costs primarily include regular inspections, cleaning up debris, and repairing minor damage. These maintenance activities are designed to maintain the integrity and performance of asphalt shingles, thereby extending their lifespan. However, over time, asphalt shingles deteriorate, cracking, breaking, etc., which is when they need to be replaced. The cost of replacing asphalt shingles includes not only the cost of purchasing new materials, but also the labor costs of removing the old shingles and installing new ones.

In order to reduce maintenance costs and extend service life, some advanced asphalt shingle products use materials and technologies that are more weather resistant. For example, certain brands of asphalt shingles use special coating technology to improve their resistance to UV rays and weathering. In addition, reasonable installation process and quality control can also significantly improve the service life of asphalt shingles.

Cost Comparison Analysis and Discussion

Initial Investment Cost Comparison: Price Difference Between Metal Shingles and Asphalt Shingles

When discussing the initial investment cost of metal shingles and asphalt shingles, the first thing we need to focus on is the market price of the two materials. Generally speaking, the initial investment cost of metal shingles is higher than that of asphalt shingles. This is mainly due to the material cost, production process and scarcity of metal tiles. According to market research data, metal shingles are usually 1.5 to 2 times more expensive than asphalt shingles.

However, this price difference does not only reflect the cost of materials, but also involves factors such as product scarcity and brand value. Metal shingles, as a relatively new roofing material, are still developing and growing in terms of production process and market demand, and are therefore relatively expensive. Asphalt shingles, as a traditional roofing material, have a mature production process and relatively stable market demand, so their price is relatively low.

In addition to material costs, installation costs are also an important factor affecting initial investment costs. Because of their light weight, stable structure and relatively easy installation, metal shingles may have lower installation costs than asphalt shingles. However, this does not mean that the total cost of metal shingles is necessarily lower than asphalt shingles. Because metal shingles are more durable and less costly to maintain, the total cost of metal shingles may gradually approach or even fall below that of asphalt shingles in the long run.

Comparison of Long-Term Repair Costs: Durability and Maintenance Costs of Metal Shingles vs. Asphalt Shingles

The durability and maintenance costs of metal versus asphalt shingles are key factors in the comparison of long-term maintenance costs. Metal shingles are known for their superior durability and are often resistant to harsh weather and corrosion, resulting in relatively low maintenance costs. In contrast, asphalt shingles have a shorter lifespan and require more frequent replacement, which increases long-term repair costs.

The average maintenance cost of metal shingles is only 30% of that of asphalt shingles. This is because the durability of metal shingles allows them to perform consistently for upwards of 50 years, while asphalt shingles typically last only about 20 years. Additionally, while the installation cost of metal shingles is initially higher, the overall cost is rather lower in the long run due to their low maintenance costs.

However, it is worth noting that the durability of metal shingles is also closely related to the quality of their materials, manufacturing process and installation techniques. Low-quality metal tiles may fail prematurely due to problems such as corrosion and flaking coatings, increasing maintenance costs. Therefore, when selecting metal tiles, attention should be paid to their materials, coating technology and manufacturing process to ensure their long-term performance.

Relationship Between Environmental Factors and Costs: the Influence of Climate and Geographic Conditions on Maintenance Costs

Climate and geographic conditions are important factors affecting roof maintenance costs. For example, in areas with variable climates, such as coastal areas or inland arid regions, roofing materials are more susceptible to erosion by natural factors such as wind, rain and sun, leading to increased frequency and cost of repairs. In contrast, areas with mild climates and low precipitation have more durable roofs that are relatively less costly to repair.

In coastal areas, for example, high salinity sea breezes can cause corrosion of roofing materials and accelerate their aging process. In this case, metal tiles are relatively inexpensive to repair due to their corrosion-resistant properties. However, in arid areas, intense UV radiation may cause asphalt shingles to age more quickly, requiring more frequent repairs and replacements. Therefore, local climatic conditions must be fully considered when choosing roofing materials.

Geographic conditions likewise have an impact on maintenance costs. For example, in earthquake-prone areas, the roof structure needs to be more resistant to earthquakes, which will increase the initial investment cost, but may also reduce damage and repair costs due to earthquakes. In addition, areas with complex terrain, such as mountainous or hilly areas, can make roofs more difficult to construct and maintain, which can lead to higher repair costs.

To more accurately assess the impact of climatic and geographic conditions on repair costs, a Life Cycle Cost Analysis (LCCA) model can be used. This model integrates the costs of each phase of roofing materials, installation, maintenance, and replacement, and considers the value for money at different points in time. The LCCA model allows for a more comprehensive assessment of the long-term cost-effectiveness of different roofing materials under different climatic and geographic conditions.

Conclusions and Recommendations

Conclusion of the Study: Summarizing and Comparing the Repair Costs of Metal Shingle and Asphalt Shingle roofs

After an in-depth study of the maintenance costs of metal shingles versus asphalt shingle roofs, we found significant differences between the two in terms of maintenance costs. Metal shingles significantly reduce long-term maintenance costs with their superior durability and long service life. In contrast, asphalt shingles, while having a lower initial investment cost, have relatively higher maintenance costs in the long run due to their shorter lifespan and frequent replacement needs.

Practical Suggestions: Choosing Appropriate Roofing Materials and Maintenance Strategies for Different Needs

In practice, it is important to choose the right roofing material and maintenance strategy for different needs. For example, for long-term durability and low maintenance costs, metal tiles may be an ideal choice. Metal shingles are durable for decades and are less susceptible to weathering due to their material properties, reducing the need for frequent replacements and repairs. According to studies, the maintenance cost of metal shingles is only about 1/3 of that of asphalt shingles. In addition, metal shingles offer excellent fire and water resistance, providing a higher level of building safety.

However, for projects with a limited budget, asphalt shingles may be a more economical option. Asphalt shingles are relatively inexpensive and cost less to install and maintain. Although they have a relatively short lifespan and need to be replaced regularly, asphalt shingles are still a cost-effective option in the short term. In addition, asphalt shingles are available in a variety of styles and colors to meet the needs of different architectural styles.

When choosing a roofing material, you also need to consider the local climate and geographic conditions. For example, in areas with a humid climate, metal shingles may be more prone to rust and corrosion, while asphalt shingles are more adaptable to this environment. Therefore, when choosing a roofing material, various factors need to be considered, including material performance, environmental suitability, maintenance costs and economic benefits.

In addition, the choice of maintenance strategy is critical. For metal tile roofs, regular cleaning and inspection is essential. This allows potential damage to be identified and repaired in a timely manner, thereby extending its lifespan. For asphalt shingle roofs, on the other hand, in addition to regular inspections and repairs, care needs to be taken to prevent problems such as moisture penetration and UV exposure.

In summary, choosing the right roofing materials and maintenance strategies for different needs is key to ensuring roof performance and affordability. By taking into account factors such as material performance, environmental suitability, maintenance costs and economic benefits, we can select the most suitable roofing materials and maintenance strategies to provide long-term stable protection for buildings. Here with SKW, we provide professional roofing solution and all kind of roofing products, click contact us to learn more.