Introducción: El viaje crítico de la fábrica al tejado

Imagínese esto: tras meses de planificación, por fin ha recibido el contenedor de tejas metálicas revestidas de piedra de primera calidad para su proyecto estrella. Abre las puertas y se encuentra con una escena de devastación. Las frágiles tejas están agrietadas, el hermoso revestimiento de piedra está arañado y, lo que es peor, toda la carga se ha desplazado y hundido dentro del contenedor debido a un endeble palé de madera desintegrado. El calendario del proyecto se ha hecho añicos, el presupuesto se ha disparado en sustituciones y retrasos, y la confianza en el proveedor ha quedado destruida.

Este escenario de pesadilla es una desafortunada realidad en el comercio mundial de materiales de construcción, especialmente para productos pesados y de formas únicas, como las cubiertas metálicas revestidas de piedra. En SKW Roof, con más de 20 años de experiencia como fabricante líderHemos sido testigos de las graves consecuencias de un envasado deficiente. Entendemos que nuestra responsabilidad no termina en la puerta de la fábrica; se extiende a garantizar que nuestros productos premium para tejados lleguen a su almacén o lugar de trabajo en las mismas perfectas condiciones en que salieron del nuestro. Este artículo profundiza en el aspecto a menudo ignorado pero crítico de transporte internacional de materiales pesados para tejados y revela el enfoque sólido y sistemático que SKW emplea para garantizar una entrega impecable y sin daños en todo el mundo.

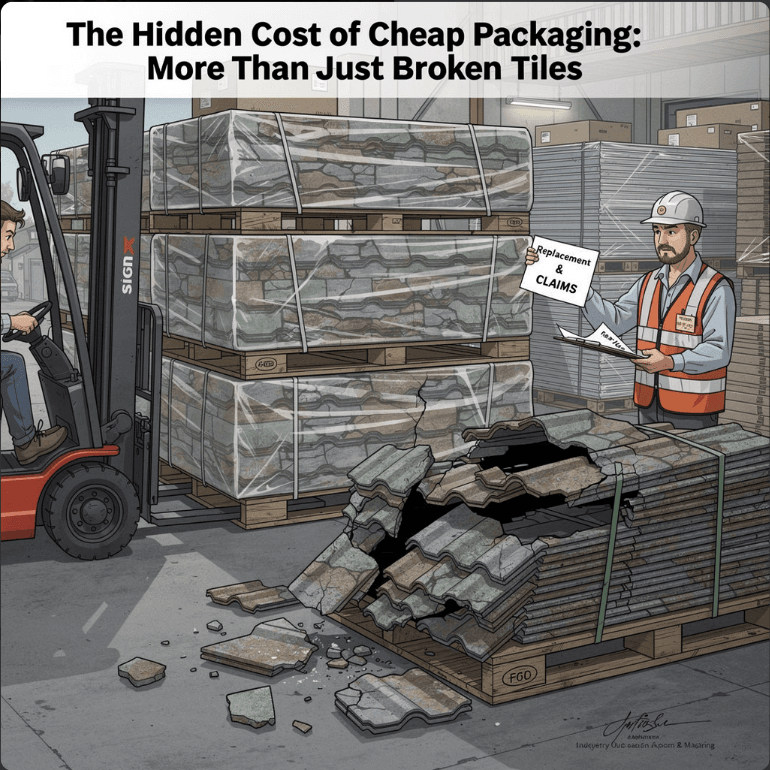

El coste oculto de los envases baratos: Algo más que baldosas rotas

Los tejados metálicos revestidos de piedra son famosos por su durabilidad excepcional, atractivo estético y resistencia a condiciones climáticas extremas. Sin embargo, estas mismas ventajas las convierten en un reto para el transporte. Son mucho más pesadas que las tejas de asfalto o las chapas metálicas estándar, y sus formas multidimensionales y entrelazadas las hacen vulnerables a la presión puntual y al movimiento.

Cuando los fabricantes hacen recortes en el envasado, los riesgos son graves y polifacéticos:

- Fallo catastrófico de la carga: El núcleo del problema suele ser la paleta. Palés de madera blanda de baja calidad, "verdes" o reciclados simplemente no pueden soportar el inmenso peso (a menudo superior a 1.000 kg por palé) durante un viaje por mar de un mes de duración. Bajo el estrés constante del oleaje y la manipulación en las terminales, estos palés pueden astillarse, combarse o hundirse por completo. Esto hace que toda la pila se desplace, caiga y aplaste las baldosas de las capas inferiores.

- Abrasión y daños en el revestimiento: Aunque el palé aguante, una sujeción insuficiente permite que las baldosas rocen entre sí y con las paredes del contenedor durante semanas. Esta abrasión puede desgastar los vibrantes azulejos resistentes a los rayos UV. revestimiento de piedra o pintura de colorcomprometer la estética incluso antes de comenzar la instalación.

- Infiltración de humedad: La madera no conforme puede albergar plagas o humedad. Durante el húmedo tránsito oceánico, esto puede provocar la aparición de moho, hongos o incluso manchas de óxido en los sustratos metálicos, a pesar de sus propiedades de resistencia a la corrosión.

- Pesadilla logística y financiera: Las consecuencias para usted, el comprador, son nefastas: envíos rechazados, costosas devoluciones, retrasos en los proyectos de construcción, clientes frustrados y pérdida de tiempo en la gestión de reclamaciones. El ahorro inicial en un producto más barato se borra al instante, multiplicado a menudo por diez por estos costes ocultos.

La diferencia SKW: Un enfoque de ingeniería para el envasado

En SKW Roof, nuestro compromiso El cliente es lo primero, transparencia y mejora continua se plasma vívidamente en nuestra filosofía de envasado. Para nosotros, el envasado no es un mero coste, sino parte integrante de nuestro negocio. solución premium para cubiertas. Nuestro sistema está diseñado para soportar los rigores de la logística mundial.

1. La base: Palets resistentes para la exportación

Nunca comprometemos los cimientos. Utilizamos palés de madera resistentes, sin fumigar y conformes a las normas de exportación diseñado específicamente para cargas pesadas.

- Material: Construidas con madera dura de alta densidad secada en horno (como el roble o el arce) o con madera contrachapada excepcionalmente resistente y conforme. Esto garantiza la máxima capacidad de carga y rigidez.

- Diseño: Los elementos clave del diseño incluyen tablas de cubierta más gruesas de lo habitual, bloques reforzados y uniones extrafuertes. Todos los palés cuentan con la certificación NIMF 15, lo que significa que están tratados térmicamente y estampados, evitando así retrasos aduaneros debidos a la normativa de bioseguridad.

- Capacidad de carga: Cada paleta está diseñada y probada para soportar con seguridad el importante peso de nuestras baldosas metálicas revestidas de piedra, con un factor de seguridad muy superior al exigido para el transporte marítimo.

2. La envoltura segura: Film estirable de alto rendimiento

Una vez que las baldosas están meticulosamente apiladas y encajadas en el palé, aplicamos film estirable industrial.

- Proceso: Utilizamos una técnica de envoltura en espiral accionada por máquina que aplica una tensión alta y constante. Normalmente aplicamos 15-20 capas de película, creando un armazón fuerte y cohesivo.

- Función: Esta película comprime la pila en una sola unidad sólida, impidiendo que se mueva cualquier baldosa individual. Protege contra el polvo, las salpicaduras de humedad y minimiza la fricción durante el transporte.

3. El cierre final: fleje de acero para una integridad máxima

La tercera capa, la más crítica, es fleje de acero (o poliéster) de gran espesor.

- Aplicación: Aplicamos múltiples correas tanto horizontal como verticalmente alrededor del palé. Las correas se tensan a una psi específica y se engarzan de forma segura.

- Propósito: Este paso no es negociable. Une el palé y la carga envuelta, evitando el efecto "rebote" que puede producirse durante el transporte de larga distancia. Aunque se apliquen fuerzas extremas, el flejado garantiza que la carga y el palet se muevan como un bloque indestructible, eliminando las fuerzas de cizallamiento que rompen los palets.

Este triple sistema de protección -palet robusto, envoltorio de compresión y fleje de acero- transforma las baldosas individuales en una unidad de envío similar a una fortaleza.

Nuestro compromiso integral de calidad y servicio

Nuestro fiable embalaje es sólo una de las facetas de trabajar con SKW. Como fabricante dedicado a suministrar soluciones de techado a empresas distribuidoras y contratistas de todo el mundoConstruimos toda nuestra actividad en torno a su éxito.

- Excelencia del producto: Ofrecemos una amplia gama de productos, entre los que se incluye nuestro visualmente impresionante Serie Galaxy de cubiertas metálicas revestidas de piedra, que combina la belleza cósmica con la durabilidad funcional, y tejas metálicas pintadas de color conocidos por su longevidad y versatilidad de diseño.

- Comunicación proactiva: Creemos en transparencia y apertura. Recibirá puntualmente listas de embalaje detalladas, fotos de los contenedores cargados antes de sellarlos y todos los documentos de envío necesarios.

- Experiencia global: Habiendo servido clientes en más de 100 paísesConocemos la documentación específica y los requisitos normativos y logísticos de las distintas regiones, lo que garantiza un proceso de despacho de aduanas sin contratiempos.

Preguntas más frecuentes (FAQ)

P1: ¿Por qué no se pueden utilizar palés más baratos y ligeros para reducir costes?

A: El mínimo ahorro en embalaje se ve astronómicamente superado por el riesgo de pérdida del producto, la gestión de reclamaciones y el daño a la reputación. Nuestro compromiso es entregar un producto perfecto. El uso de embalajes de calidad técnica no es negociable para garantizar la fiabilidad, que es una parte esencial de nuestra política de calidad. misión y valores.

P2: ¿Cómo se gestiona la carga dentro del contenedor de transporte?

A: Nuestro experimentado equipo de logística utiliza abrazaderas para contenedores, bolsas de aire inflables y materiales de estiba adecuados para garantizar que cada paleta quede bien sujeta dentro del contenedor, sin dejar espacio para desplazamientos longitudinales o laterales durante el viaje.

P3: ¿Qué debo hacer al recibir el contenedor?

A: Recomendamos realizar una inspección visual del exterior de los contenedores y del estado de los palés nada más descargarlos. Documente con fotos cualquier daño apreciable en el embalaje antes de descargarlo. Nuestros embalajes transparentes facilitan la inspección inicial del producto.

P4: ¿Ofrecen distintos envases para distintos destinos?

A: Sí. Nuestros estándares de embalaje son uniformemente elevados, pero tenemos en cuenta factores como el tiempo total de tránsito, los protocolos de manipulación en el puerto de destino y el clima estacional (por ejemplo, la estación de los monzones) para realizar cualquier pequeño ajuste proactivo en nuestros métodos de sujeción.

Conclusión: Asociarse con confianza, construir con seguridad

Elegir un proveedor de cubiertas es algo más que catálogos de productos y listas de precios. Se trata de elegir un socio fiable que gestione toda la cadena de suministro con profesionalidad y previsión. El protocolo de embalaje de SKW es un símbolo tangible de nuestra dedicación a innovación, trabajo en equipo y dar prioridad al cliente.

Invertimos en un embalaje superior para que usted no tenga que pagar el impuesto oculto de las mercancías dañadas. Esto le permite centrarse en lo que mejor sabe hacer: proyectos de construcción y techado con confianza, sabiendo que los materiales que llegan a la obra están impolutos, completos y listos para instalar.

¿Está listo para experimentar el estándar de calidad SKW desde la fábrica hasta el tejado? Póngase en contacto con nuestro equipo hoy mismo para hablar de las necesidades de su proyecto y recibir un presupuesto detallado. Permítanos demostrarle cómo nuestro compromiso con la excelencia en cada detalle, especialmente en la entrega global segura, nos convierte en el socio de confianza de distribuidores y contratistas de todo el mundo.

Visite nuestro sitio web en https://skwroof.com/ para explorar toda nuestra gama de metal recubierto de piedrasoluciones para cubiertas de metal pintado en color y tejas de asfalto.