La Trinidad de la Carga: Ingeniería de acciones compuestas

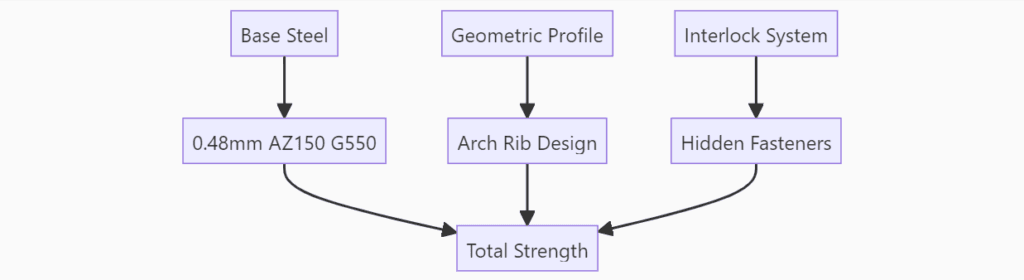

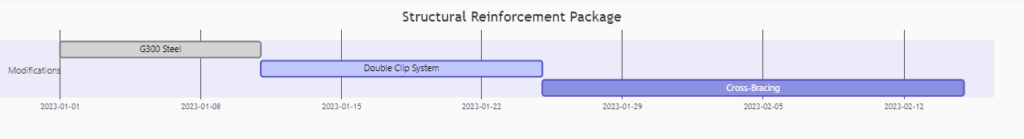

Sistema de Sinergia Estructural:

Especificaciones de la ciencia de los materiales:

| Componente | Especificación | Norma de ensayo | Significado |

|---|---|---|---|

| Núcleo de acero | G550 AZ150 | ASTM A792/A792M | Resistencia a la tracción 550MPa |

| Peso del revestimiento | AZ150 | EN 10346 | 150 g/m² de zinc-aluminio |

| Límite elástico | 550 MPa | ISO 6892-1 | Resistencia a la deformación |

Rendimiento de carga estática: Nieve y equipos

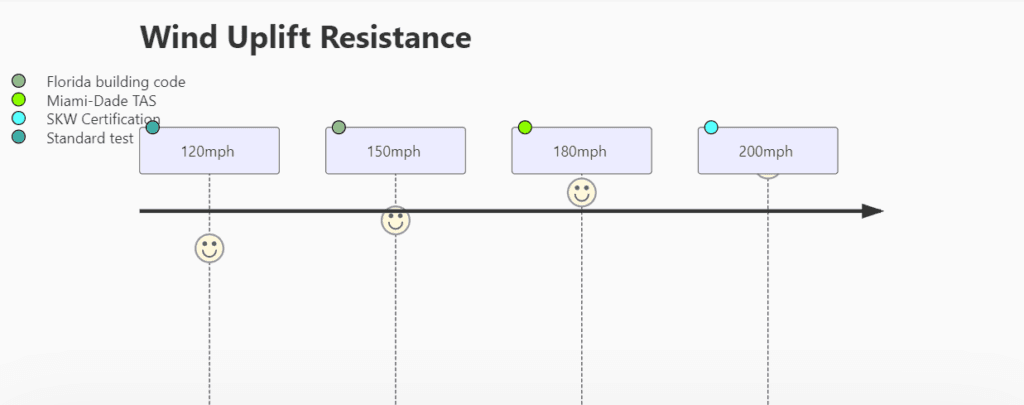

Hitos de la certificación:

- UL 580 Levantamiento por viento Clase 120

- ASTM E1592 Clasificación para condiciones meteorológicas severas

- Superó una carga estática de 300 psf (supera la mayoría de los códigos de construcción)

- Aprobación FM Global 1-90

Resistencia a la carga dinámica: Viento e impacto

Datos de simulación de huracanes:

Resultados de las pruebas de impacto:

| Energía de impacto | Resultado | Equivalente en el mundo real |

|---|---|---|

| 110 ft-lbs | Sin ruptura | 2×4 madera @ 100mph |

| 170 ft-lbs | Pequeña abolladura | Piedra de granizo de 4″ de diámetro |

| 240 ft-lbs | Fallo controlado | Rama de árbol @ 50lbs |

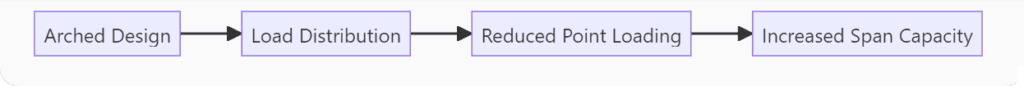

Ingeniería geométrica: El principio del arco

Mecánica de diseño de perfiles:

Comparación del rendimiento de Span:

| Espaciado | Teja Tradicional Span Max | SKW Max Span |

|---|---|---|

| 16″ o.c. | 8′-0″ | 14′-6″ |

| 24″ c.a. | No recomendado | 10′-9″ |

| 32″ o.c. | Prohibido | 8′-4″ |

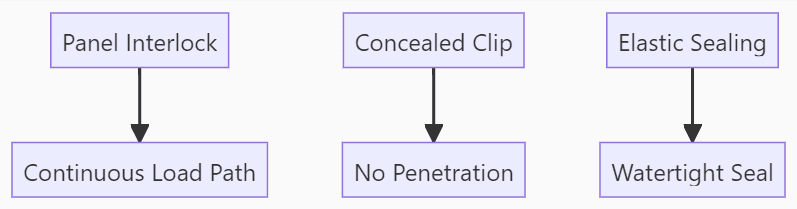

Tecnología de fijación: Sistema de abrazadera oculta

Ventajas del enclavamiento mecánico:

Resistencia al levantamiento por viento:

| Tipo de instalación | Presión de fallo | Mejora |

|---|---|---|

| Sujetador expuesto | 90 psf | Línea de base |

| Sistema de clip oculto | 300 psf | 233% |

Estudio de caso: Carga de nieve extrema

Proyecto: Estación alpina, Alpes suizos

Desafío: 400 cm de nevada anual + vientos de 120 mph

Solución SKW:

Métricas de rendimiento:

- Carga de nieve soportada de 290psf (3× código local)

- Deformación cero tras 15 ciclos de congelación-descongelación

- Reducción de los costes de mantenimiento: 75% frente a cubiertas tradicionales

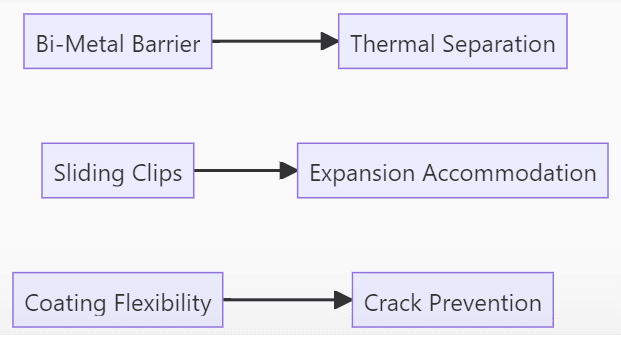

Gestión de la carga térmica

Tecnología de control de la expansión:

Medidas de movimiento:

| Temp Delta | Movimiento cada 10 pies | Tejado convencional | Sistema SKW |

|---|---|---|---|

| 100°F | 0.45″ | Daños por pandeo | Cero estrés |

| 150°F | 0.68″ | Fallo de la junta | Movimiento controlado |

Comportamiento sísmico

Datos de simulación de terremotos:

| Magnitud | Desplazamiento | Resultado |

|---|---|---|

| 6,0 Richter | 3,5″ lateral | Sin daños |

| 7,2 Richter | 8,7″ lateral | Deformación menor del clip |

| 8,0 Richter | 12,0″ lateral | Daños reparables |

Característica única:

- Sistema de clip autorregulable

- Deformación del acero dúctil antes del fallo

- Revestimiento de piedra no quebradizo

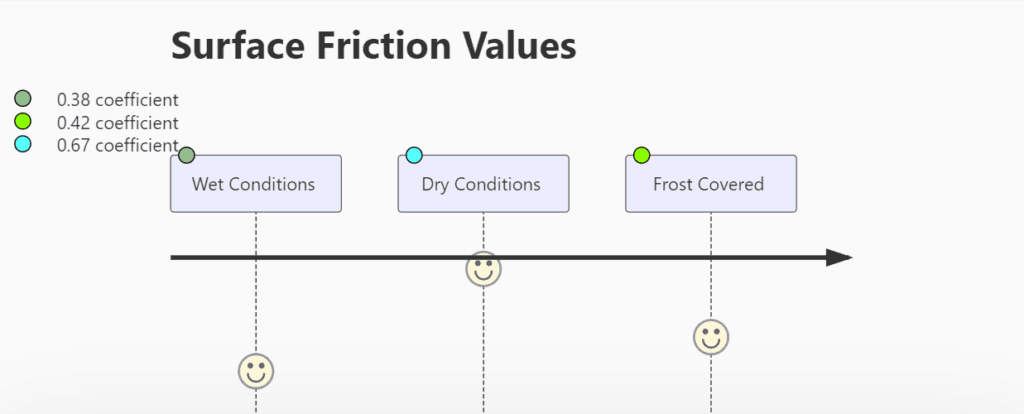

Consideraciones sobre la carga de instalación

Sistema de seguridad al caminar:

Tecnología de distribución de cargas:

- Caminos de costillas reforzadas

- Tecnología de gránulos antideslizantes

- Placas separadoras de carga puntual

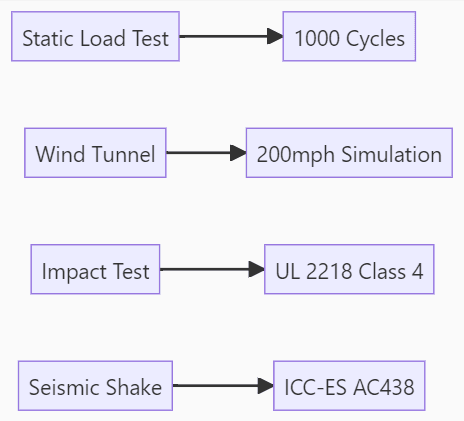

Metodología de las pruebas de carga

Proceso de certificación:

Equipos de ensayo:

- Bastidor de carga hidráulico de 400.000 lb

- Tobera de túnel de viento de 8×8 pies

- Cámara de intemperismo acelerado

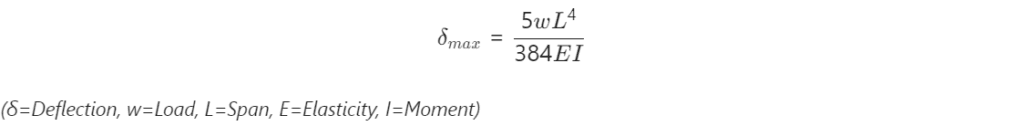

Directrices para el cálculo estructural

Fórmulas de ingeniería:

Coeficientes de rendimiento SKW:

| Parámetro | Valor | Ventaja |

|---|---|---|

| E (Módulo elástico) | 203 GPa | 3× hormigón |

| I (Momento de inercia) | 0,89 pulg⁴/pie | Aumento 40% |

| Tensión admisible | 345 MPa | 28% superior |

Factores de degradación:

- La resistencia a la corrosión mantiene la integridad del acero

- Los revestimientos estables a los rayos UV evitan la fragilización

- Los materiales no absorbentes evitan daños por congelación

Documentación técnica

Vídeos de ensayos estructurales

Certificaciones: UL 580 - FM 4471 - ASTM E1592 - ICC-ES AC438 - CE EN 15601

Las cubiertas SKW están diseñadas para resistir las fuerzas más extremas de la naturaleza, desde las cargas de nieve de Alaska hasta los huracanes del Caribe. Nuestro sistema estructural compuesto ofrece una capacidad de carga entre 2 y 3 veces superior a la de las cubiertas tradicionales, verificada por laboratorios independientes y en condiciones reales en los entornos más exigentes del mundo.