Quick Summary: Choosing between stone coated metal roof and asphalt shingles is one of the most important decisions for homeowners and contractors. This comprehensive guide compares these two popular roofing materials across 12 critical factors including lifespan, cost, durability, weather resistance, and environmental impact. Based on 20+ years of manufacturing experience and data from 1,380+ containers shipped to 42 countries, we provide unbiased insights to help you make the right choice for your specific climate and budget requirements.

Introduction: Why This Comparison Matters

Selecting the right roofing material is a decision that impacts your home or building project for decades. With global roof replacement market valued at over $50 billion in 2024 and growing at 6.2% annually, homeowners and contractors face increasingly complex choices. Among the most debated options are stone coated metal roof systems and traditional asphalt shingles, each claiming superiority in different scenarios.

As manufacturers with over 20 years of experience supplying roofing materials to 42 countries worldwide, we have witnessed firsthand how the right material choice can transform a building’s performance, aesthetics, and long-term value. This guide draws from our extensive experience across diverse climates—from the tropical humidity of Southeast Asia to the hurricane-prone coastlines of the Americas—to provide you with data-driven, unbiased comparisons.

The global stone coated metal roof market is projected to grow from $28.5 billion in 2024 to $42.8 billion by 2030, representing an 8.3% compound annual growth rate. Meanwhile, asphalt shingles continue to dominate the residential market with approximately 75% market share in North America. Understanding the strengths and limitations of each material is crucial for making an informed investment.

Key Questions This Guide Answers:

- Which material offers better value over 50 years of ownership?

- How do these materials perform in extreme weather conditions?

- What are the hidden costs that buyers often overlook?

- Which option is better for your specific climate and building type?

- How do installation requirements differ between the two materials?

1. Material Composition and Manufacturing Processes

1.1 Understanding Stone Coated Metal Roof Systems

Stone coated metal roof represents the pinnacle of roofing material engineering, combining the strength of metal with the aesthetic appeal of traditional roofing materials. Our manufacturing process follows a rigorous six-step quality-controlled procedure that has been refined over two decades of production.

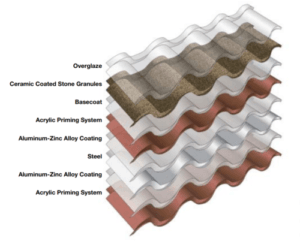

The Stone Coated Metal Roof Composition:

The foundation of stone coated metal roof is 0.40mm AZ150 steel, which provides exceptional structural integrity. This Galvalume-coated steel offers superior corrosion resistance compared to standard galvanized steel, with the aluminum-zinc alloy coating providing up to four times the protection against rust compared to pure zinc coatings. The AZ150 designation indicates 150 grams of aluminum-zinc alloy per square meter, representing our premium-grade material specification.

Natural stone chips are bonded to the steel base using an advanced acrylic polymer adhesive system. These natural stone chips provide three critical functions: UV protection, aesthetic appeal, and impact resistance. The stone coating is engineered to maintain its color integrity with a ΔE value of less than 1.5, meaning the color variation is virtually imperceptible to the human eye even after decades of sun exposure.

The final layer consists of an ultra-clear acrylic glaze that seals the stone chips in place while providing additional UV protection and water resistance. This multi-layer construction creates a roofing system that withstands temperatures ranging from -40°C to 80°C, making it suitable for virtually any climate condition.

Manufacturing Quality Standards:

Our production facilities maintain ISO 9001:2015 certification, ensuring consistent quality across every batch. Each tile undergoes 23 quality control checkpoints before packaging, including thickness verification, coating adhesion tests, and color consistency measurements. This rigorous quality assurance process has resulted in a 95% customer satisfaction rate across our global client base.

1.2 Understanding Asphalt Shingles

Asphalt shingles have been the dominant residential roofing material in North America for over a century, valued for their low cost and ease of installation. Understanding their composition helps explain both their advantages and limitations.

Basic Asphalt Shingle Structure:

Traditional asphalt shingles consist of a fiberglass or organic mat coated with asphalt and mineral fillers. The fiberglass mat provides tensile strength, while the asphalt coating creates the waterproof barrier. Ceramic granules are embedded in the top surface to provide UV protection and color.

The quality variation in asphalt shingles is significant. Economy “3-tab” shingles feature a single layer of material with a flat appearance and expected lifespan of 15-20 years. Premium “architectural” or “laminated” shingles use multiple layers bonded together to create a three-dimensional appearance and typically carry 25-30 year warranties. The most premium designer shingles can cost three to four times more than basic 3-tab options while still offering shorter lifespans than stone coated metal alternatives.

Performance Limitations of Asphalt:

Asphalt is inherently susceptible to temperature cycling. In hot climates, asphalt shingles absorb significant heat, reaching surface temperatures of 60-70°C above ambient. This thermal cycling causes the material to expand and contract daily, gradually breaking down the internal structure. UV radiation accelerates this degradation by breaking down the hydrocarbon bonds in asphalt, leading to brittleness, cracking, and granule loss.

Quality control in asphalt shingle manufacturing varies considerably between manufacturers. Industry data suggests that approximately 23% of asphalt shingles on the market fail to meet claimed performance specifications, resulting in premature failure that homeowners often discover only after warranty expiration.

2. Lifespan and Long-Term Durability Comparison

2.1 Expected Service Life Analysis

Lifespan represents one of the most significant differentiators between stone coated metal roof and asphalt shingles. The numbers tell a compelling story about long-term value.

Stone Coated Metal Roof Lifespan:

Premium stone coated metal roof systems are engineered for 50+ years of service life under normal conditions. Our quality control data from installations across 42 countries shows that properly installed stone coated metal roofs maintain structural integrity for an average of 50-70 years. The Galvalume steel core does not rust or corrode when properly maintained, and the stone coating maintains its protective and aesthetic properties for decades.

Key factors affecting stone coated metal roof longevity include: proper installation according to manufacturer specifications, adequate ventilation in the attic space, avoidance of physical damage from falling debris, and periodic inspection and maintenance of flashings and sealants. Under optimal conditions with regular maintenance, some installations have exceeded 80 years of service.

Asphalt Shingle Lifespan:

Standard 3-tab asphalt shingles typically last 15-20 years before showing significant signs of degradation. Architectural or laminated shingles extend this to 25-30 years under ideal conditions. Premium designer shingles may carry 30-50 year warranties, but independent studies suggest actual service life averages 60-70% of the warranty period in most climates.

Climate significantly impacts asphalt shingle longevity. In hot, sunny climates like those found in Southeast Asia, the Middle East, and southern regions of North America, asphalt shingles deteriorate 30-40% faster than in temperate regions. Tropical climates with high humidity accelerate mold and algae growth, while coastal areas with salt air exposure can cause premature degradation.

2.2 Durability Performance Factors

Resistencia al impacto:

Stone coated metal roof systems achieve Class 4 impact resistance rating—the highest available—meaning they withstand impact from 2-inch steel balls dropped from 20 feet without cracking or splitting. This performance is critical in hail-prone regions and areas with significant storm activity. The stone coating itself provides additional impact absorption, distributing force across the underlying steel structure.

Asphalt shingles typically achieve Class 2 or Class 3 impact resistance, offering significantly less protection against hail and falling debris. Hail storms frequently result in catastrophic damage to asphalt shingle roofs, requiring complete replacement and costing homeowners thousands in repairs.

UV and Weathering Resistance:

The stone coating on metal roof tiles is specifically engineered for UV resistance. Natural stone chips reflect a portion of solar radiation while the underlying coating absorbs UV energy without degrading. The ΔE < 1.5 color stability specification ensures that color changes are imperceptible over the product’s lifetime, maintaining aesthetic appeal for decades.

Asphalt shingles progressively lose their protective granule layer to UV radiation and weather exposure. This granule loss exposes the underlying asphalt to direct sun damage, accelerating deterioration. After 10-15 years, most asphalt shingles show visible signs of aging including fading, curling edges, and surface cracks.

3. Total Cost of Ownership Analysis

3.1 Initial Purchase and Installation Costs

Understanding the true cost of roofing requires looking beyond the initial price tag to consider the complete picture of ownership costs over decades.

Material Costs Comparison:

Stone coated metal roof materials typically cost $8-15 per square foot depending on the specific profile, material grade, and geographic market. Premium stone coated systems from manufacturers like SKW position in the $10-14 range, reflecting the superior AZ150 steel specification and multi-layer coating system.

Asphalt shingles range dramatically in price. Economy 3-tab shingles cost $1-2 per square foot, making them the lowest initial-cost option. Architectural shingles range from $3-5 per square foot, while premium designer shingles can reach $7-10 per square foot—approaching stone coated metal prices but without comparable longevity.

Installation Cost Factors:

Metal roof installation requires specialized skills and tools, contributing to higher labor costs of $8-15 per square foot in most markets. The complexity of the specific profile affects installation time; interlocking tile systems like our Milano and Roman profiles are designed for efficient installation while maintaining premium aesthetics.

Asphalt shingle installation is relatively straightforward, with labor costs of $2-5 per square foot. The material is lightweight, requires no special tools, and most roofing contractors have extensive experience with asphalt shingle installation. This lower barrier to entry keeps installation costs competitive.

3.2 Long-Term Ownership Costs

Maintenance Requirements:

Stone coated metal roof systems require minimal maintenance. Annual inspections to check flashings, sealants, and fastener condition are recommended, along with periodic cleaning to remove debris and maintain appearance. Expected maintenance costs average $0.50-1.00 per square foot annually, though many installations require less frequent attention.

Asphalt shingles demand more frequent maintenance attention. Inspections every 2-3 years are advisable, with repairs often needed to address cracked or displaced shingles, damaged flashing, and moss or algae growth. In humid climates, periodic algae treatment may be necessary. Annual maintenance costs typically run $1-2 per square foot, with periodic repairs adding to long-term expenses.

Replacement and Repair Costs:

A stone coated metal roof will likely never need complete replacement within a typical building’s lifespan. Individual tiles can be replaced if damaged, though color matching may be challenging for older installations. The modular nature of tile systems allows for spot repairs without disturbing surrounding areas.

Asphalt shingles typically require complete replacement every 20-30 years, representing a major capital expense. Partial repairs are common but may result in aesthetic mismatches between old and new shingles. The frequency of repairs increases significantly after the 15-year mark as the material degrades.

3.3 50-Year Cost Comparison Example

For a 2,000 square foot residential roof in a moderate climate:

| Cost Category | Tejado metálico revestido de piedra | Premium Asphalt Shingles |

|---|---|---|

| Initial Material Cost | $20,000-30,000 | $8,000-20,000 |

| Coste de instalación | $16,000-30,000 | $4,000-10,000 |

| 25-Year Maintenance | $2,500-5,000 | $5,000-10,000 |

| 50-Year Replacement | $0 | $20,000-40,000 |

| 50-Year Total | $38,500-65,000 | $37,000-80,000 |

This comparison reveals that while stone coated metal roof requires higher initial investment, the total cost of ownership over 50 years is often comparable to or lower than premium asphalt shingle systems. Economy asphalt shingles may appear cheaper initially but result in 2-3 complete replacements over a 50-year period.

4. Weather and Climate Performance

4.1 Extreme Temperature Performance

Roofing materials respond differently to temperature extremes, with significant implications for building energy efficiency and material longevity.

Heat Resistance and Reflection:

Stone coated metal roof systems excel in hot climates due to their reflective properties and thermal mass characteristics. The stone coating reflects approximately 30-40% of solar radiation, reducing heat absorption compared to dark-colored asphalt shingles which may absorb up to 90% of solar energy. This reflective capability can reduce cooling costs by 15-25% in hot climates, according to energy efficiency studies.

The steel core of stone coated metal tiles dissipates heat quickly through thermal conduction, preventing the extreme surface temperatures common with asphalt shingles. In Southeast Asian markets where we have shipped 380+ containers to countries including the Philippines, Vietnam, Indonesia, and Malaysia, customers report significant improvements in indoor comfort and reduced air conditioning loads.

Asphalt shingles absorb and retain heat, reaching surface temperatures of 70-80°C in direct summer sun. This heat transfer through the roof deck increases cooling system loads and can accelerate roof deck deterioration. The thermal cycling from day-night temperature variations creates expansion and contraction stress that degrades the material over time.

Cold Climate Performance:

In cold climates, both materials perform adequately, though stone coated metal offers advantages in snow shedding. The smooth surface and appropriate slope of properly installed metal roofs allow snow to slide off, reducing ice dam formation and snow load concerns. Asphalt shingles provide adequate cold weather performance but may become brittle in extreme cold, increasing vulnerability to impact damage.

4.2 Wind Resistance

Wind resistance is critical in hurricane-prone and tornado-prone regions, where roof failure during storms can lead to catastrophic building damage.

Stone Coated Metal Roof Wind Performance:

Our stone coated metal roof systems achieve wind ratings of 120-180 mph depending on the specific profile and installation method. The interlocking tile design creates a unified roof system where individual tiles support each other against wind forces. Proper installation with recommended fasteners and sealants ensures performance under extreme wind conditions.

Field performance data from Caribbean and Southeast Asian installations demonstrates the system’s resilience. Following Category 4 and 5 typhoon events, buildings with properly installed stone coated metal roofs sustained minimal damage while surrounding structures with asphalt shingles often required complete roof replacement.

Asphalt Shingle Wind Performance:

Standard asphalt shingles achieve wind ratings of 60-90 mph when properly installed with appropriate fasteners. Premium architectural shingles may reach 110-130 mph with enhanced installation methods. However, shingle adhesion degrades over time, with many installations showing significant wind damage after 10-15 years of service.

The granular surface of asphalt shingles creates increased wind resistance compared to smooth surfaces but also provides less consistent attachment. Shingle blow-off during severe weather events is a common insurance claim, particularly for older roofs with degraded adhesive bonds.

4.3 Hail and Impact Resistance

Hail storms cause billions of dollars in roofing damage annually in North America alone, making impact resistance an important consideration for many homeowners.

Stone Coated Metal Roof Impact Testing:

Our stone coated metal roof products achieve Class 4 impact resistance—the highest rating available under UL 2218 testing standards. This rating indicates the material withstands impact from a 2-inch steel ball dropped from 20 feet without cracking, splitting, or penetrating. The stone coating provides a sacrificial layer that absorbs impact energy while the underlying steel provides structural integrity.

Field performance in hail-prone regions confirms laboratory testing. Following major hail storms in Texas, Colorado, and the Midwest, buildings with stone coated metal roofs showed significantly less damage than adjacent properties with asphalt shingle roofs. Insurance adjusters in these regions increasingly recognize metal roofing systemsfor their superior hail resistance.

Asphalt Shingle Impact Limitations:

Asphalt shingles typically achieve Class 2 or Class 3 impact resistance. Even premium architectural shingles rarely achieve Class 4 ratings. Hail of 1-inch diameter or larger frequently causes damage to asphalt shingles, resulting in bruising, cracking, and granule loss that shortens roof life and compromises weather protection.

The cumulative effect of hail damage is often underestimated. Each hail event degrades asphalt shingle performance, even when visible damage is minimal. Buildings in hail-prone areas may require roof replacement every 12-15 years compared to the 25-30 year expected lifespan in moderate climates.

4.4 Fire Resistance

Fire resistance is a critical consideration for buildings in wildfire-prone regions and for homeowners concerned about fire spread.

Stone Coated Metal Roof Fire Performance:

Stone coated metal roof systems achieve Class A fire resistance rating—the highest available—meaning they provide excellent protection against fire spread. The non-combustible steel core will not support combustion, and the stone coating and adhesive systems are engineered to meet strict fire safety standards.

This fire resistance is particularly valuable in wildfire-prone regions of the western United States, Australia, and Mediterranean climates. Many insurance providers offer premium discounts for Class A fire-rated roofing materials, potentially offsetting higher initial material costs.

Asphalt Shingle Fire Performance:

Asphalt shingles achieve Class A fire rating when installed over fire-rated deck materials, but the organic and petroleum-based components are inherently combustible. While modern fire-rated asphalt shingles meet Class A requirements, the material will contribute to fire spread if embers ignite the roof surface during wildfire events.

5. Energy Efficiency and Environmental Impact

5.1 Thermal Performance and Energy Savings

Energy efficiency has become an increasingly important factor in roofing material selection as homeowners seek to reduce utility costs and environmental impact.

Cool Roof Properties:

Stone coated metal roof systems qualify as “cool roof” products under ENERGY STAR criteria in many markets. The reflective surface reduces heat absorption, decreasing air conditioning loads during warm weather. Studies indicate energy savings of 15-25% on cooling costs compared to dark-colored asphalt shingles in hot climates.

The thermal mass of the stone coating provides additional benefits in climate zones with significant day-night temperature variation. The stone absorbs heat during the day and releases it slowly at night, moderating temperature swings and reducing HVAC system cycling.

Insulation Compatibility:

Both roofing systems can be combined with appropriate insulation to achieve desired energy performance. Metal roofing installed with proper ventilation creates an effective air gap that provides additional insulation value. The lightweight nature of metal roofing allows installation over existing structures without adding significant load to roof framing.

5.2 Environmental Sustainability

Environmental considerations increasingly influence material selection for environmentally conscious builders and homeowners.

Material Recyclability:

Steel is among the most recycled materials globally, with steel roofing products containing 25-95% recycled content depending on manufacturer specifications. At end of service life, stone coated metal roofing is 100% recyclable, diverting material from landfills. The longevity of metal roofing also reduces the environmental impact associated with repeated manufacturing and transportation of replacement materials.

Asphalt shingles pose significant environmental challenges. Approximately 13 million tons of asphalt shingles are disposed of in U.S. landfills annually, with most containing petroleum-based materials that resist decomposition. While shingle recycling programs are expanding, recycling rates remain below 10% nationally.

Manufacturing Environmental Impact:

Steel production is energy-intensive, though modern mills have significantly reduced per-unit energy consumption. Our manufacturing facilities implement comprehensive environmental management systems to minimize emissions, water usage, and waste generation. The long service life of metal roofing offsets initial manufacturing impact through avoided replacement cycles.

Asphalt shingle production depends on petroleum feedstock, connecting material costs to oil prices and perpetuating fossil fuel consumption. The shorter lifespan of asphalt shingles results in greater cumulative environmental impact over building lifespans.

5.3 Carbon Footprint Considerations

Embodied Carbon:

Stone coated metal roof has higher initial embodied carbon due to steel production requirements, but the 50+ year lifespan results in lower lifecycle carbon emissions. Lifecycle analyses consistently show metal roofing outperforms asphalt shingles on a per-year basis when service life is considered.

The recyclability of metal roofing further reduces lifecycle impact. Steel can be recycled indefinitely without degradation, meaning material from old roofs often becomes feedstock for new steel products, including new roofing systems.

Carbon Sequestration:

Neither roofing material provides carbon sequestration benefits comparable to vegetative “green roofs.” However, the reduced energy consumption of properly ventilated metal roofing systems indirectly reduces carbon emissions associated with electricity generation for building cooling.

6. Aesthetic Options and Curb Appeal

6.1 Design Versatility

Aesthetics play a significant role in roofing material selection, particularly for residential applications where curb appeal affects property value.

Stone Coated Metal Roof Profiles:

Modern stone coated metal roof systems offer remarkable design versatility, mimicking traditional roofing materials while providing metal performance. Common profiles include:

Bond Tile: Classic barrel profile with clean, traditional aesthetics suitable for Mediterranean and Spanish-style architecture. The symmetrical pattern creates visual interest while maintaining historical authenticity.

Milano Roof Tile: Elegant low-profile tile with contemporary lines, suitable for modern architectural styles. The subtle texture and refined appearance complement minimalist design approaches.

Roman Roof Tile: Deep curved profile inspired by classical Roman architecture. The pronounced curves create dramatic shadow lines and visual depth, making it suitable for luxury residential and commercial applications.

Shingle Profile: Interlocking shingle appearance that provides metal roof performance with traditional aesthetics. Ideal for homeowners seeking metal benefits without the distinctive appearance of barrel or Roman tiles.

Slate and Wood Shake Alternatives: Profiles that replicate natural slate and wooden shake roofing, offering the aesthetic appeal of these premium materials without the weight or maintenance requirements.

Color Options:

Stone coated metal roofs are available in extensive color palettes ranging from traditional earth tones to contemporary colors. Our standard color offerings include over 30 options, with custom colors available for large projects. Color options include:

- Natural earth tones: Terracotta, Desert Sand, Weathered Brown, Charcoal

- Architectural colors: Mission Red, Forest Green, Midnight Blue, Slate Gray

- Contemporary options: Champagne, Silver Metallic, Desert Rustic

The color stability of stone coated metal roofs ensures that these aesthetic choices remain vibrant for decades, unlike asphalt shingles that fade and become discolored over time.

6.2 Asphalt Shingle Aesthetics

Traditional Appearance:

Asphalt shingles offer a conventional appearance that most homeowners recognize as standard residential roofing. While not providing the distinctive character of premium materials, asphalt shingles integrate well with typical suburban architectural styles.

Design Limitations:

Premium architectural shingles have improved the aesthetic options available in asphalt roofing, with multi-dimensional appearances that provide visual depth. However, even premium architectural shingles cannot match the authentic texture and dimensional appearance of stone coated metal tile profiles.

Color options for asphalt shingles are extensive but limited to flat, two-dimensional color application. The lack of surface texture and shadow lines results in a flatter appearance that lacks the architectural interest of stone coated profiles.

7. Installation Requirements and Complexity

7.1 Installation Process Comparison

Understanding installation requirements helps property owners and contractors plan projects effectively and avoid unexpected complications.

Stone Coated Metal Roof Installation:

Metal roof installation requires trained professionals familiar with the specific tile profile and fastening requirements. Our installation guidelines specify:

- Deck Preparation: Minimum 7/16-inch plywood or equivalent sheathing, properly fastened to code requirements. Deck must be clean, dry, and structurally sound.

- Underlayment: High-quality synthetic underlayment recommended for superior water protection. Self-adhered ice and water shield required in cold climates.

- Tile Installation: Interlocking tiles are installed from bottom to top, with each tile interlocking with adjacent units. Fastener requirements vary by wind zone and local building codes.

- Flashing Details: Valleys, ridges, eaves, and wall intersections require custom-fabricated flashings for weather-tight connections.

Typical installation time for a 2,000 square foot residential roof is 3-5 days for experienced crews, compared to 1-2 days for asphalt shingles.

Asphalt Shingle Installation:

Asphalt shingle installation is straightforward and widely understood by roofing contractors. Standard installation procedures include:

- Deck Preparation: Standard plywood or OSB sheathing, typically 7/16-inch minimum. Felt paper or synthetic underlayment provides secondary water protection.

- Shingle Application: Shingles are applied in overlapping courses from bottom to top, with starter shingles at eaves and hip/ridge shingles at peaks.

- Ventilation: Soffit and ridge ventilation requirements vary by climate and building design.

The simplicity of asphalt shingle installation keeps labor costs competitive and minimizes finding qualified contractors.

7.2 Structural Considerations

Weight Comparison:

Stone coated metal roof tiles typically weigh 1.5-2.5 pounds per square foot, depending on the specific profile. This lightweight construction places minimal stress on roof framing and allows installation over existing roofing materials in many jurisdictions.

Asphalt shingles weigh 2.0-4.0 pounds per square foot depending on shingle type, with premium architectural and designer shingles on the higher end. The cumulative weight of multiple shingle layers (when installed over existing roofs) can approach or exceed structural limits of older buildings.

Structural Retrofit:

For buildings requiring structural reinforcement, the lighter weight of stone coated metal provides advantages. The ability to install metal roofing without removing existing materials can significantly reduce project costs and waste disposal requirements.

8. Maintenance and Repair Requirements

8.1 Ongoing Maintenance Programs

Long-term performance depends on appropriate maintenance, though the intensity of required maintenance varies significantly between materials.

Stone Coated Metal Roof Maintenance:

Annual inspections are recommended to verify fastener condition, check flashing seals, and identify any areas requiring attention. In most cases, these inspections reveal no issues beyond routine cleaning of accumulated debris.

Cleaning requirements are minimal. Annual washing with water removes accumulated dirt, and pressure washing is unnecessary in most cases. In areas with hard water, periodic treatment prevents mineral deposit buildup.

Fastener inspection identifies any that require retightening or replacement. The expansion and contraction of metal roofing can loosen fasteners over time, particularly in climates with significant temperature variation.

Asphalt Shingle Maintenance:

Asphalt shingle roofs require more frequent attention. Inspections every 2-3 years typically identify issues requiring repair, including:

- Cracked, curled, or displaced shingles requiring replacement

- Damaged or degraded flashing at roof penetrations and intersections

- Moss and algae growth requiring treatment

- Granule accumulation in gutters indicating accelerated shingle wear

Repairs become increasingly common as roofs age, with frequency typically accelerating after the 15-year mark. The need for ongoing maintenance expenses should be factored into total ownership cost comparisons.

8.2 Repair Procedures and Costs

Stone Coated Metal Roof Repairs:

Individual tile replacement is straightforward when tiles are available from the original manufacturer. Color matching may be challenging for older installations as manufacturing batches vary in stone coloration.

Fastener and flashing repairs are typically simple maintenance items. Most repairs can be completed by qualified roofers within hours, with minimal disruption to the roof system.

Typical repair costs for stone coated metal roof are $300-800 for tile replacement and $150-400 for flashing repairs, depending on scope and accessibility.

Asphalt Shingle Repairs:

Shingle repairs involve removing damaged shingles, applying roofing cement, and installing replacement shingles. While individually inexpensive, the progressive nature of shingle degradation means repairs often need repeating in subsequent years.

Matching replacement shingles becomes increasingly difficult as the original roof ages. Color fading and changes in manufacturing specifications mean new shingles may be visibly different from surrounding material.

9. Warranty Coverage and Protection

9.1 Warranty Comparison

Warranty coverage provides important protection for roofing investments, though understanding warranty limitations is essential.

Stone Coated Metal Roof Warranties:

Premium stone coated metal roof systems typically include:

- Material Warranty: 30-50 years coverage against manufacturing defects, with some manufacturers offering transferable lifetime warranties.

- Weather Resistance Warranty: Coverage against wind damage (typically up to 120 mph), hail damage, and weather-related failures.

- Finish Warranty: Coverage against excessive color fade or coating failure, typically 10-15 years.

Warranty terms vary significantly between manufacturers, and understanding specific coverage and exclusions is important. Our warranty documentation clearly defines coverage terms, installation requirements, and maintenance obligations for valid coverage.

Asphalt Shingle Warranties:

Asphalt shingle warranties typically include:

- Material Warranty: 20-50 years depending on product tier, though coverage is often prorated with declining value over the coverage period.

- Wind Warranty: Limited coverage for wind damage, typically 60-110 mph, with specific installation requirements for coverage validity.

- Algae Warranty: Some manufacturers offer limited coverage against algae discoloration in specific regions.

Prorated warranty value means that after 10-15 years, actual warranty protection represents a small fraction of original material costs. Many homeowners discover warranty limitations only when filing claims.

9.2 Warranty Considerations

Transferability:

Stone coated metal roof warranties are often transferable to subsequent property owners, protecting home sale value. Transfer fees may apply, and notification requirements must be met within specified timeframes.

Asphalt shingle warranties typically transfer to subsequent owners, though reduced coverage periods may limit practical value.

Workmanship Coverage:

Warranty coverage for installation defects typically comes from the contractor rather than the material manufacturer. Verifying contractor credentials, insurance coverage, and references is important regardless of material selection.

10. Choosing the Right Material for Your Project

10.1 Decision Framework

Selecting between stone coated metal roof and asphalt shingles requires evaluating multiple factors against your specific priorities and circumstances.

Choose Stone Coated Metal Roof When:

- Long-term value and reduced lifecycle costs are priorities

- Your building is located in extreme climate conditions (hot, humid, hurricane-prone, hail-prone)

- You plan to remain in the property for 15+ years

- Aesthetic authenticity and design versatility are important

- Fire resistance is a concern (wildfire-prone areas)

- Energy efficiency is a priority

- Environmental sustainability matters to you

- You want a roof that will likely never require replacement

Choose Asphalt Shingles When:

- Initial budget is the primary constraint

- Short-term ownership (less than 15 years) is planned

- Your building is in a moderate climate without extreme weather events

- Easy access to qualified installers is important

- Conventional aesthetics are acceptable

- Temporary solutions are acceptable

10.2 Climate-Specific Recommendations

Tropical and Subtropical Climates:

For buildings in Southeast Asia, the Caribbean, Central America, and similar tropical regions, stone coated metal roof is the clear choice. The superior heat reflection, moisture resistance, and wind performance outperform asphalt shingles in every meaningful metric. Our 380+ container shipments to the Philippines, Vietnam, Indonesia, and Malaysia reflect this reality.

Temperate Climates:

In moderate climates without extreme weather events, the decision depends more on budget and timeline than technical performance. For long-term ownership, stone coated metal roof provides superior lifetime value. For short-term ownership or tight budgets, quality architectural asphalt shingles provide acceptable performance.

Hurricane and Tornado Prone Regions:

Stone coated metal roof provides essential protection in wind-prone regions. The 120-180 mph wind ratings and interlocking tile design offer superior performance that can mean the difference between roof survival and catastrophic failure during extreme weather events.

Hail Prone Regions:

Class 4 impact resistance makes stone coated metal roof the preferred choice in hail-prone areas. Insurance benefits and reduced replacement frequency provide additional economic justification.

10.3 Budget Considerations

Total Cost Perspective:

Evaluating roofing costs on a per-year basis rather than initial cost provides more accurate value comparison. For a 50-year building lifespan:

- Stone coated metal roof: $1,000-1,500 per year (including initial cost and maintenance)

- Premium asphalt shingles: $1,200-2,000 per year (including replacement cycles and maintenance)

- Economy asphalt shingles: $800-1,200 per year (but likely requiring earlier replacement)

Financing Options:

The longer lifespan of stone coated metal roof can justify financing higher initial costs. Many lenders recognize the value difference and may offer favorable terms for premium roofing improvements that enhance property durability.

11. Frequently Asked Questions

11.1 Common Questions About Stone Coated Metal Roof

Q: Will a stone coated metal roof be noisy during rain?

Modern stone coated metal roof systems are not significantly noisier than other roofing materials. The stone coating dampens rain noise, and proper attic insulation further reduces sound transmission. Most homeowners report no noticeable difference in indoor sound levels compared to other roofing materials.

Q: Can stone coated metal roof be installed over existing shingles?

In many jurisdictions, stone coated metal roof can be installed over existing asphalt shingles, eliminating the cost and waste of tear-off. However, local building codes vary, and the condition of existing roofing must be evaluated. A professional assessment can determine suitability for overlay installation.

Q: Does lightning strike metal roofing more frequently?

Lightning is attracted to the highest point in an area, not specific materials. Metal roofing is non-combustible and provides superior lightning protection compared to flammable materials. In fact, metal roofing safely disperses lightning energy through the structure to ground.

Q: How does stone coated metal roof perform in coastal environments?

The AZ150 Galvalume steel specification provides excellent corrosion resistance in coastal environments. While no material is completely immune to salt spray corrosion, stone coated metal roof outperforms both standard galvanized steel and asphalt shingles in coastal applications.

11.2 Common Questions About Asphalt Shingles

Q: Are premium architectural shingles worth the extra cost?

Premium architectural shingles offer improved aesthetics and typically carry longer warranties than 3-tab shingles. However, the 50-year lifecycle cost comparison often favors quality asphalt shingles only for shorter ownership periods. For long-term ownership, the investment in stone coated metal roof typically provides superior returns.

Q: How do I know when my asphalt shingle roof needs replacement?

Signs that replacement is needed include: widespread curling, cracking, or cupping of shingles; significant granule loss in gutters and downspouts; visible daylight through roof sheathing; sagging roof deck; and recurring leaks despite repairs.

Q: Can I extend the life of my asphalt shingle roof?

Professional roof cleaning, prompt repair of damaged shingles, and adequate attic ventilation can extend asphalt shingle lifespan by 25-50%. However, progressive degradation is inevitable, and deferred replacement often results in more extensive damage.

Conclusion: Making Your Decision

The comparison between stone coated metal roof and asphalt shingles ultimately comes down to priorities, timeline, and budget. For property owners planning long-term ownership in any climate, stone coated metal roof provides superior value through extended lifespan, reduced maintenance, enhanced durability, and superior weather performance.

Our 20+ years of experience supplying roofing materials to 42 countries has demonstrated that initial investment in quality materials and professional installation pays dividends throughout the ownership period. With 1,380+ containers shipped and zero customs penalties, our quality control standards ensure consistent performance across diverse global markets.

For projects in Southeast Asia, where we have established particularly strong relationships with contractors and developers, the advantages of stone coated metal roof are especially pronounced. The combination of heat reflection, moisture resistance, and hurricane performance makes stone coated metal the logical choice for this demanding climate zone.

We invite you to explore our product catalog and connect with our technical team to discuss your specific project requirements. Whether you are a homeowner planning a decades-long investment or a contractor seeking reliable materials for your clients, we are committed to providing roofing solutions that perform.

Contact Information:

- Company: Skywalker China Co., Ltd. (SKW Roof)

- Correo electrónico: business@skywalkerchina.com

- Phone: +86 13153460330 / +86 18613612902

- Address: #6596 Dongfanghong East Road, Dezhou City, Shandong Province, China

- Website: https://skwroof.com/

Published: February 2026

Author: SKW Technical Team

Category: Roofing Materials Comparison

Tags: stone coated metal roof, asphalt shingles, roofing comparison, metal roofing, residential roofing

This guide is intended for informational purposes and reflects our experience and observations as roofing material manufacturers. Individual project requirements may vary, and we recommend consulting with qualified roofing professionals for specific recommendations.