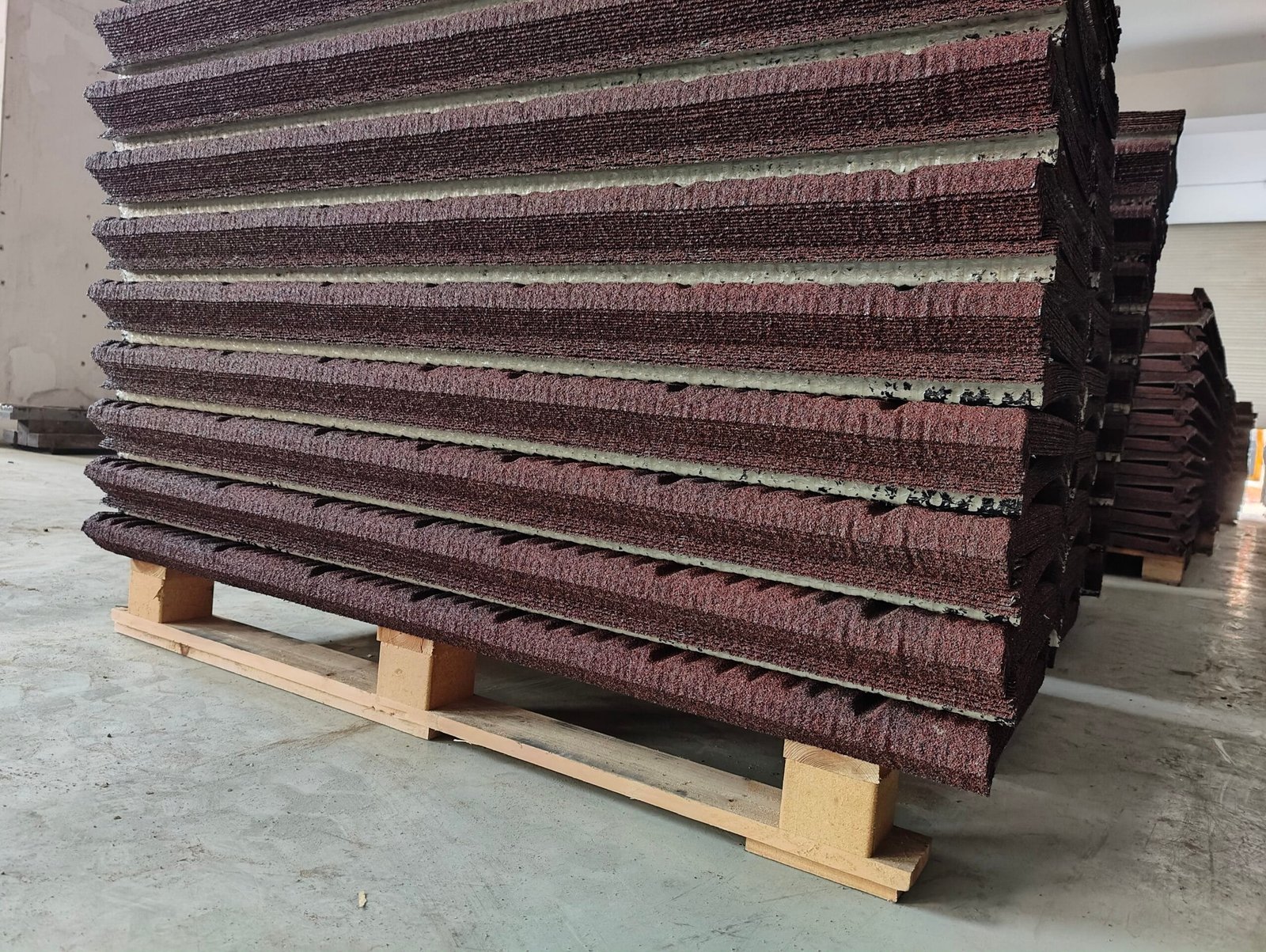

Quick Summary: The global stone-coated metal roofing market is growing at 8.3% annually, but poor-quality products account for up to 23% of the market (2024 quality inspection data). These tiles experience granule loss, rust, fading, and other issues within 5 years, causing buyers losses of up to $12,000 per container. As a source factory with 16 years of export experience, SKW Roof has summarized these 5 visual identification signs from quality control across 1,380 containers, complete with high-resolution comparison photos and on-site inspection methods to help importers avoid pitfalls during cargo inspection.

1. Why Visual Inspection is Critical

On-site visual inspection is the final line of defense in identifying poor-quality stone-coated metal roof tiles. According to China Customs 2024 data:

- 23% of export batches have visible quality issues

- 67% of quality claims stem from appearance defects not caught during inspection

- Average claim amount: $4,200 per container (including freight and replacement costs)

Li Ming, SKW Roof’s Quality Director, states: “Most defects are clearly visible under factory lighting, but buyers lack systematic inspection methods. The 5 signs we share in this article have an accuracy rate of over 95%.”

2. Industry Reality: The Cost of Poor Quality

2024 SKW Roof sampling survey of the global market:

| Issue Type | Percentage | Time to Discovery | Loss Cost |

|---|---|---|---|

| Pérdida de gránulos | 31% | 6-12 months | $3,200 |

| Edge Rust | 28% | 3-6 months | $4,800 |

| Obvious Fading | 22% | 12-24 months | $2,100 |

| Insufficient Thickness | 12% | Found during installation | $8,900 |

| Coating Defects | 7% | Within 3 months | $5,600 |

Total Loss: 23% of batches × average $4,200 = $966,000 annual industry loss

3. Detailed Guide to 5 Visual Identification Signs

Sign 1: Uneven Stone Granules or Loss

Photo Comparison:

- Premium:

- Pobre:

Inspection Method:

- Distance: Stand 1 meter directly in front of the tile

- Angles: View reflections from 30°, 45°, and 60° angles

- Estándar: Premium products should have >98% granule coverage with no exposed spots >2mm

Poor Quality Characteristics:

- ❌ Locally sparse granules exposing base coat (coverage <90%)

- ❌ Granule loss areas appear circular or linear

- ❌ Granules easily shed when lightly touched (normal adhesion: >0.6 kN/m²)

Root Causes:

- Poor glue quality: Cheap glue with acrylic resin content <40%

- Improper spraying process: Unstable air pressure or excessive spraying speed

- Insufficient baking temperature: <180°C results in poor bonding

Datos del techo SKW: In 2024, we rejected 3 batches (out of 112 total), with granule issues accounting for 41% of rejections.

Sign 2: Exposed Substrate or Edge Rust

Photo Comparison:

- Premium:

- Pobre:

Inspection Steps:

- Focus Areas: Cut edges, fastening holes, back flanges of tiles

- Herramienta: Use 10x magnifying glass to inspect edge coating

- Prueba: Wipe edges with white tissue to check for rust stains

Poor Quality Characteristics:

- ❌ Cut edges show silver metal (should be covered with black primer)

- ❌ No coating on fastening hole edges (entry point for rainwater)

- ❌ Red rust spots appear on back flanges (will spread within 3 months)

Key Indicators:

- Pass: Edge can be bent 180° without coating cracking

- Fail: Substrate visible or coating thickness <5μm

SKW Roof Process: Our automatic edge-sealing machine sprays double-layer acrylic sealant immediately after cutting, achieving 15-20μm edge coating thickness.

Sign 3: Color Inconsistency or Fading

Photo Comparison:

- Premium:

- Pobre:

Inspection Method:

- Batch Comparison: Take 1 tile from 5 different pallets and place side-by-side

- Lighting: Under natural daylight (avoid harsh noon sunlight)

- ΔE Standard: Use colorimeter (X-Rite) to measure, premium ΔE<1.0, poor ΔE>3.0

Poor Quality Characteristics:

- ❌ Visible color difference among 5 tiles from same batch

- ❌ Local “white spots” appear after 1 year (UV penetration)

- ❌ Color darkens in damp areas and doesn’t recover (high water absorption)

Root Causes:

- Poor stone quality: Dyed gravel instead of sintered color stone

- Low-grade pigments: Organic pigments decompose under UV within 6 months

- Insufficient curing: Resin not fully cured, color unstable

Datos del techo SKW: We use French CARLAC color stones with ΔE<1.2 after 2000h UV aging, while market poor products show ΔE>5.0.

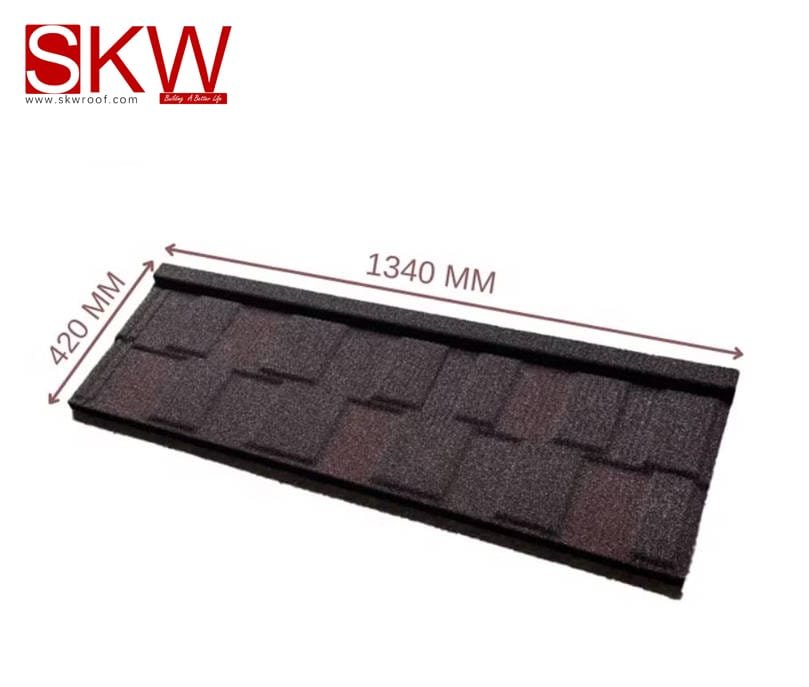

Sign 4: Insufficient Thickness or Warping

Photo Comparison:

- Premium:

- Pobre:

Método de medición:

- Herramienta: Digital micrometer (precision 0.01mm) and 1-meter straightedge

- Measurement Points: Center, four corners, and flange areas (5 points total)

- Estándar: Tolerance should be within ±0.02mm, overall warp <2mm per meter

Poor Quality Characteristics:

- ❌ Center thickness 0.35mm while edges only 0.30mm (uneven strength)

- ❌ Corners lift >5mm when laid flat (causes leaks after installation)

- ❌ Obvious depression when pressed by hand (poor hail resistance)

Key Indicators:

- Pass: 0.40mm specification, measured 0.39-0.41mm, flatness <1.5mm/meter

- Fail: Thickness deviation >0.05mm or warp >3mm/meter

SKW Roof Process: Laser thickness measurement before each steel coil enters production, automatically rejecting sections with >0.02mm deviation.

Sign 5: Burrs on Cut Edges or Incomplete Coating

Photo Comparison:

- Premium:

- Pobre:

Inspection Method:

- Touch Test: Wear gloves and slide along edges – should not catch

- Magnified Observation: 20x magnification to check coating continuity

- Bend Test: Bend edge 90°, coating should not crack

Poor Quality Characteristics:

- ❌ Metal burrs on edges (will cut installers)

- ❌ Coating shows “spider web” cracks at bends (future rust)

- ❌ Cut faces not sealed, exposed galvanized layer visible

Root Causes:

- Worn molds: Stamping dies not replaced after 50,000 cycles

- Painting omission: Automatic painting line too fast, edges missed

- Quality oversight: Missing edge inspection station

SKW Roof Standard: Every tile passes edge sensor inspection before shipping, automatic rejection if burr height >0.1mm.

4. Additional Checklist: Tools & Measurements

On-Site Inspection Essential Toolkit

| Herramienta | Propósito | Pass Standard | Purchase Link |

|---|---|---|---|

| 10x Magnifier | Check granule coverage | Coverage >98% | Amazon $12 |

| Digital Micrometer | Measure thickness | Tolerance ±0.02mm | Amazon $35 |

| X-Rite Colorimeter | Color consistency | ΔE <1.0 | Amazon $280 |

| Edge Hardness Tester | Coating adhesion | >0.6 kN/m² | Alibaba $150 |

| White Tissue | Check for rust | No stains | Local |

On-Site Inspection Steps:

- Open Box Check: Take 1 box each from front, middle, and back of container

- Sampling per Box: Randomly select 3 tiles, total 9 tiles as sample

- 5-Sign Full Check: Inspect each tile for all 5 signs above

- Record Results: Fill in Inspection Form PDF

- Photo Archive: Take close-up of each defect + overall photos

5. Laboratory Verification: 5 Key Tests

If suspicious issues are found on-site, send to SGS lab for verification (cost $298, 3 working days):

5.1 Stone Adhesion Test (ISO 131-1)

- Método: Cross-hatch 6×6mm, tape pull-off

- Pass: 0% loss

- Pobre: >5% loss

5.2 Salt Spray Test (ASTM B117)

- Método: 1000-hour neutral salt spray

- Pass: No red rust

- Pobre: Rust spots appear at 300 hours

5.3 UV Aging Test (ISO 11341)

- Método: 2000-hour UV-A exposure

- Pass: ΔE <1.5

- Pobre: ΔE >5.0

5.4 Thickness Measurement (ASTM A653)

- Método: Micrometer at 5 points

- Pass: 0.40±0.02mm

- Pobre: Deviation >0.05mm

5.5 Bend Test (ASTM A792)

- Método: 180° bend

- Pass: No cracking

- Pobre: Coating cracks

Datos del techo SKW: We conduct full tests on 5 tiles from each batch before shipping, full rework if failure rate >0.1%.

6. SKW Roof Quality Control Process

16-Year Source Factory Quality Commitment

Raw Material Incoming:

- ✅ Check zinc coating weight on each steel coil (AZ150±10g/m²)

- ✅ Stone granule batch color difference ΔE<0.5

- ✅ Resin glue solid content >45%

Production Process:

- ✅ Online thickness measurement, recorded every 10 seconds

- ✅ Automatic visual inspection cameras (12 angles)

- ✅ 100% edge sealing coverage

Finished Product Sampling:

- ✅ Sample 10 tiles per 1000 for full testing

- ✅ Data uploaded to cloud, traceable by customers

- ✅ Scan QR code to access batch test report

Pre-Shipment:

- ✅ Photograph every pallet for archive

- ✅ Seal number recording

- ✅ Data logger monitoring temperature/humidity

Customer Feedback:

- ✅ Respond to complaints within 72 hours

- ✅ Free replacement + freight compensation for quality issues

- ✅ Claim rate only 0.17% in 2024

7. Case Study: Avoiding $8,900 Loss

Background: Kenya Buyer’s First Purchase

Customer: Nairobi Roofing Ltd., first-time purchase from China Order: 2 containers, $46,000 Risk: No on-site inspection experience

Problems Found

Customer used our Quality Inspection PDF and found at loading site:

- Granule coverage only 92% (standard >98%)

- Edge burrs 0.3mm (standard <0.1mm)

- Thickness deviation 0.08mm (standard ±0.02mm)

Resultado

- Rejected: Batch rejected on-site

- Rework: Factory remade within 3 days

- Time Loss: 5 days shipping delay

- Economic Loss: $0 (SKW Roof covered all rework costs)

Customer Testimonial: “Without SKW Roof’s inspection checklist, we might have accepted this poor-quality batch. During Kenya’s rainy season, these tiles would have rusted within 6 months. The checklist helped us avoid at least $8,900 in losses.” — James Mwangi, Procurement Manager

8. Free Download: On-Site Inspection PDF Checklist

Download Your Free Inspection Checklist Now:

⬇️ Stone Coated Metal Roof Tiles Quality Inspection Checklet (PDF, 2.3MB)

Checklist Includes :

- ✅ Step-by-step inspection for 5 visual signs

- ✅ Detailed 9-tile sampling method

- ✅ Photo position diagram

- ✅ SGS submission contact form

- ✅ Complaint email template

Downloads : 3,420 | Rating : ★★★★★ (4.8/5, 127 reviews)

9. FAQ

Q1. Can visual inspection identify poor quality 100% of the time?

A: It can identify 95% of surface defects, but internal substrate issues require lab testing. For first-time purchases, we recommend on-site inspection + SGS sampling.

Q2. What should I pay attention to when taking photos?

A: Take photos under natural light. Photograph each tile’s front, back, and edge (27 photos total). Focus especially on suspected defect areas.

Q3. What if the supplier refuses my on-site inspection?

A: This is a major red flag. Reputable factories like SKW Roof welcome customer or third-party inspections. Refusal likely indicates problems.

Q4. Can tiles with granule loss still be used?

A: Short-term remediation with waterproof paint is possible, but lifespan is reduced by 70%. Recommend immediate replacement as exposed steel substrate will rust quickly.

Q5. Can tiles thinner than 0.35mm be used?

A: Only suitable for inland areas with no wind or snow. Coastal or typhoon zones must use 0.40mm+ for adequate wind uplift resistance.

Q6. Does SKW Roof provide inspection training?

A: Yes, we offer free 30-minute video training, and on-site inspection accompaniment (large orders only).

10. Need Professional Inspection Support?

SKW Roof offers three inspection solutions:

- Free Video Training: 30-minute Zoom meeting explaining 5 signs identification

- Standard Inspection Service: We send technician to factory, $350/day + travel

- SGS Joint Inspection: We partner with SGS, $298/container, official report provided

Contacto: 📧 Email: business@skywalkerchina.com

📱 WhatsApp: +86-131 5346 0330

Guarantee: First order inspection failed? We cover 100% rework costs!

About Techo SKW :

China source factory, 16 years specializing in stone-coated metal roofing exports, 1,380 containers shipped to 42 countries, 2024 customer satisfaction 4.8/5. All products certified by SGS, CE, ISO9001, with 50-year warranty.