Los ingenieros de SKW explican por qué la durabilidad del revestimiento dorsal es más importante de lo que cree

Introducción: El revestimiento posterior: el héroe olvidado de las cubiertas metálicas

Los tejados metálicos revestidos de piedra suelen llamar la atención por sus gránulos de piedra frontales, pero la revestimiento posterior de aluzinc es el protector silencioso de la longevidad del tejado. He aquí su importancia:

- Resistencia a la corrosión: Evita la oxidación en ambientes húmedos y ácidos.

- Integridad estética: Evita que la parte trasera se decolore, lo que podría mostrar a través de techos.

- Protección estructural: Refuerza el núcleo metálico para evitar deformaciones.

Capítulo 1: 3 tecnologías de revestimiento dorsal de Aluzinc al descubierto

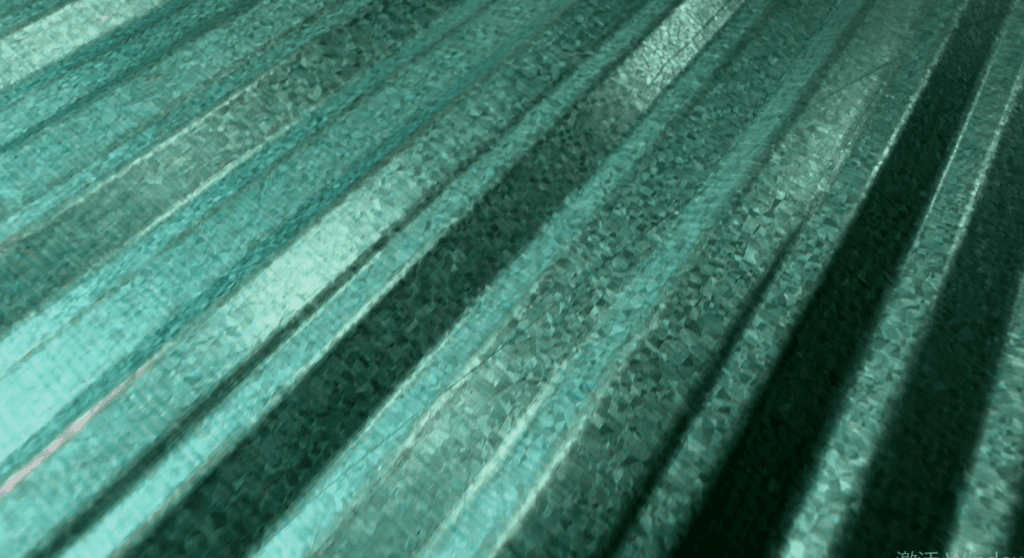

1. Revestimiento resistente a las huellas dactilares

- Mecanismo: Se aplica una fina película similar a un esmalte (transparente o verde) mediante el método de recubrimiento por rodillo.

- Pros:

- Es rentable para proyectos con un presupuesto ajustado.

- El proceso de producción es rápido, lo que permite una rápida entrega.

- Proporciona una resistencia básica a los arañazos para daños menores durante la manipulación.

- Contras:

- Limitación de la durabilidad: Falla al cabo de 3-5 años. La prueba de niebla salina ASTM B117 muestra la formación de óxido después de 500 horas.

- Vulnerabilidad medioambiental: Se desprende en entornos con un pH de 2-12, lo que es habitual en zonas industriales.

- Casos de uso ideales: Proyectos residenciales a corto plazo (menos de 5 años) o estructuras temporales.

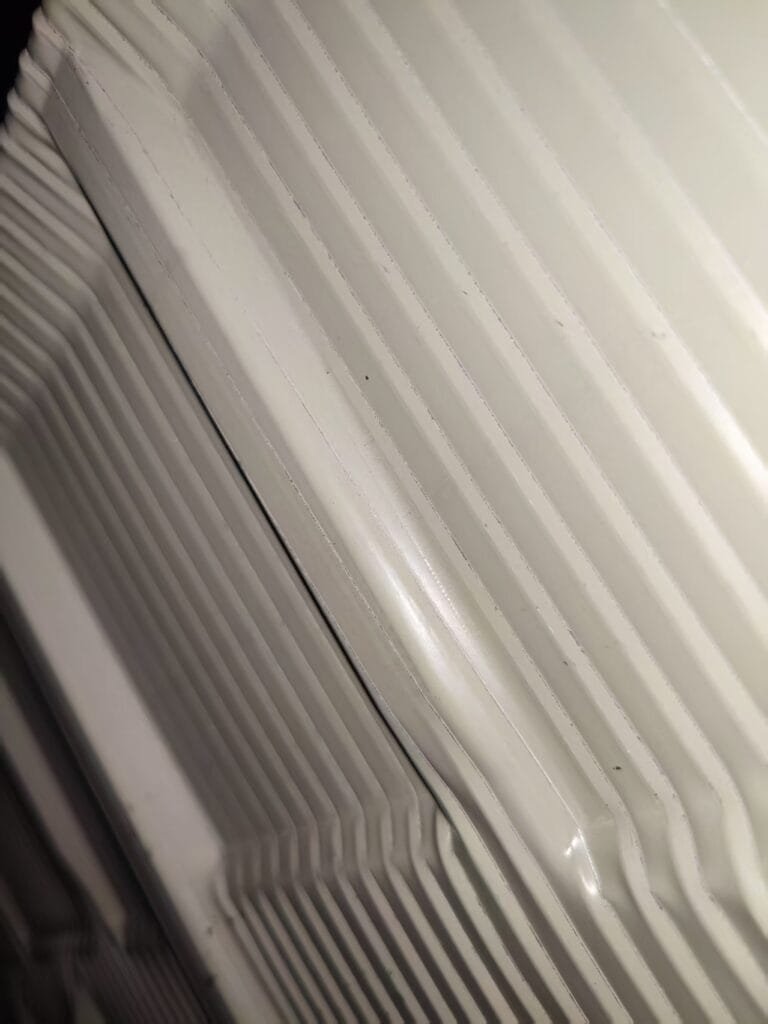

2. Reverso - Revestimiento pintado

- Innovación SKW: Sistema multicapa compuesto por una imprimación, una capa de acabado y un agente de curado, con aditivos patentados.

- Pros:

- Longevidad: Tiene una garantía de más de 15-20 años, y las fórmulas premium pueden durar incluso más de 20 años.

- Flexibilidad estética: Puede combinarse con diversos estilos arquitectónicos, como el rojo terracota para edificios históricos.

- Barrera antihumedad: Sella el metal de la humedad, lo que es crucial en climas costeros y tropicales.

- Datos de laboratorio:

- En la prueba de envejecimiento QUV (5.000 horas), el cambio de color ΔE es inferior a 3 (según la norma ISO 4892, esto significa una pérdida de color insignificante).

- En la prueba de niebla salina (ASTM B117), no hay formación de óxido después de 1.500 horas.

- El legado de la industria: Con más de 50 años de tecnología de metal prepintado, su estabilidad está demostrada.

- Casos de uso ideales: Proyectos residenciales y comerciales a largo plazo, edificios en climas húmedos y proyectos en los que la estética es un factor clave.

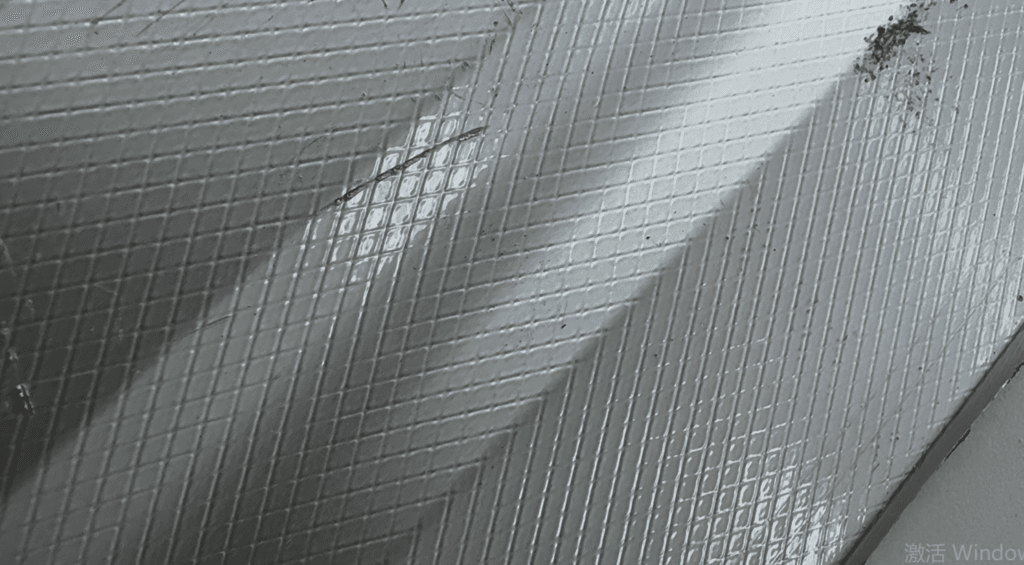

3. Nanofilm de polímero

- Mecanismo: Se lamina una película de fluorocarbono sobre el acero, y esta tecnología se utilizó originalmente para instalaciones ganaderas.

- Pros:

- Resistencia química extrema: Puede soportar un rango de pH de 2-12 para un uso a corto plazo.

- Protección temporal: Es adecuado para zonas industriales con riesgos inmediatos de corrosión.

- Contras:

- Defecto de durabilidad: Se despega al cabo de 5-8 años, con el mismo problema de adherencia que los revestimientos resistentes a las huellas dactilares.

- Ineficiencia de costes: Es 30% más caro que los revestimientos pintados por detrás, pero no ofrece ningún valor a largo plazo.

- Estudio de caso: En una explotación ganadera de Shandong, la película 60% se peló al cabo de 6 años, lo que provocó la formación de óxido.

- Casos de uso ideales: Proyectos industriales de corta duración (menos de 8 años) en zonas con exposición química extrema.

Capítulo 2: Matriz de comparación técnica

| Característica | Resistente a las huellas dactilares | Espalda - Pintada (SKW) | Nanofilm de polímero |

|---|---|---|---|

| Vida útil | 3-5 años | 15-20+ años | 5-8 años |

| Coste | Bajo ($/m²) | Moderado | Alta |

| Resistencia a la corrosión | Pobre (500 horas de niebla salina) | Excelente (1.500 horas de niebla salina) | Bueno (1.000 horas de niebla salina) |

| Personalización estética | Limitado (2-3 colores) | Alta (10+ colores) | Bajo (1-2 colores) |

| Resistencia a la humedad | Pobre (85% fallo RH) | Excelente (85% RH estable) | Moderado |

Capítulo 3: La ventaja competitiva del revestimiento dorsal de SKW

SKW no se limita a "ofrecer revestimientos", sino que diseña soluciones para los retos del mundo real:

- Formulaciones a medida:

- Se añaden aditivos resistentes a la humedad para climas tropicales y húmedos.

- Se incluyen agentes inhibidores del moho para evitar las manchas negras durante las estaciones lluviosas.

- Excelencia en los procesos:

- Grosor de la pintura: Oscila entre 8-12μm (la media del sector es de 5-7μm, y nuestro revestimiento más grueso proporciona una mayor resistencia a la corrosión).

- Precisión de curado: Utiliza un curado en horno de 220℃, que evita que la pintura se vuelva quebradiza debido a las oscilaciones de temperatura.

- Liderazgo en garantías: Ofrecemos una garantía de 20 años para los revestimientos pintados por detrás. Si el revestimiento falla, lo sustituiremos de forma gratuita.

Capítulo 4: Guía del comprador: evite las estafas del revestimiento dorsal

- Informes de pruebas de demanda:

- Para los revestimientos pintados por la parte posterior, la prueba de niebla salina debe durar al menos 1.000 horas (ASTM B117).

- Para el nanofilm, el contenido de fluorocarbono debe ser al menos 70% (comprobado por espectroscopia FTIR).

- Inspeccionar Espesor: Utilice un micrómetro. Los revestimientos pintados por detrás deben tener un grosor mínimo de 8μm.

- La letra pequeña de la garantía: Asegúrese de que la garantía cubre fallo del revestimiento posterior (no sólo la capa de piedra frontal).

- Ensayo de flexión in situ: Doble una muestra 180°. Los revestimientos pintados por la parte posterior no deben presentar grietas.

Capítulo 5: Futuro de los revestimientos dorsales de aluzinc

Las tendencias del sector indican lo siguiente:

- Recubrimientos de base biológica: Reducen los COV manteniendo la durabilidad.

- Tecnologías de autocuración: Microcápsulas que pueden reparar arañazos.

- Control de calidad basado en IA: Inspección del revestimiento 100% mediante visión artificial.

Conclusión: Invierta en el revestimiento dorsal adecuado

El revestimiento posterior es el "escudo invisible" que determina la vida útil de su tejado. Para una durabilidad a largo plazo y un control estético, Parte trasera de SKW - revestimiento pintado es el patrón oro.

👉 Actúa:

- Descargue nuestro Guía técnica del revestimiento dorsal: [https://skwroof.com/download/]

- Solicite una muestra gratuita de revestimiento: [https://skwroof.com/contact-us/)