革命性的生产技术

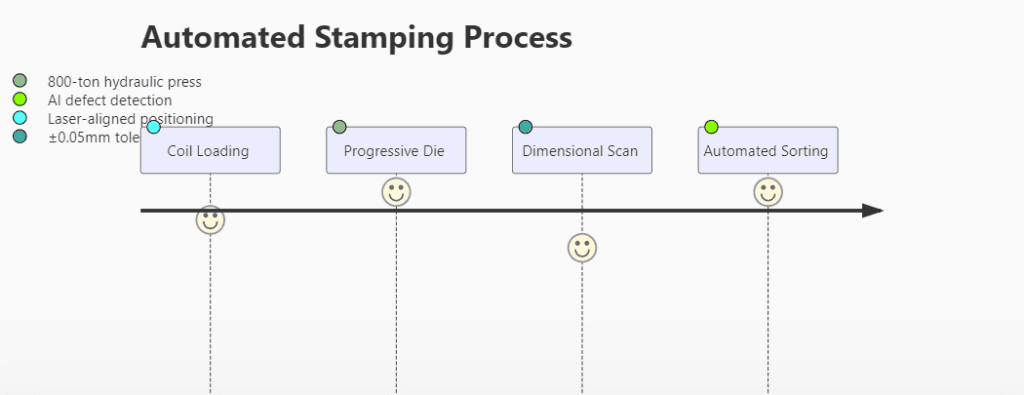

1.全自动冲压:超越人类能力的精度

机器人冲压系统规格

质量影响:

| 参数 | 手工生产 | SKW 自动化 | 改进 |

|---|---|---|---|

| 尺寸公差 | ±1.5 毫米 | ±0.1毫米 | 15x |

| 生产一致性 | 87% | 99.97% | 13% |

| 剔除率 | 5.2% | 0.03% | 173x |

"我们的机器人压力机达到了与航空航天部件同等的精度" - ISO 9001 审核报告 #SKW-2025

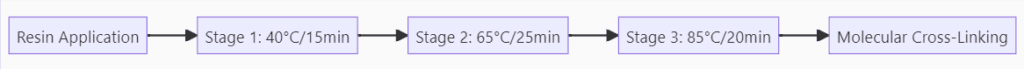

2.超长干燥技术:粘合革命

60 分钟固化科学

性能验证:

| 测试方法 | 标准干燥(20 分钟) | SKW 流程(60 分钟) | 改进 |

|---|---|---|---|

| 粘合强度 | 28 兆帕 | 45 兆帕 | 61% |

| 抗紫外线 | 2,000 小时 | 10,000+ 小时 | 5x |

| 颗粒保留 | 82% 25 年后 | 98% 25 年后 | 20% |

红外热成像技术确认:

- 树脂完全聚合

- 涂层无冷点

- 均匀的交联密度

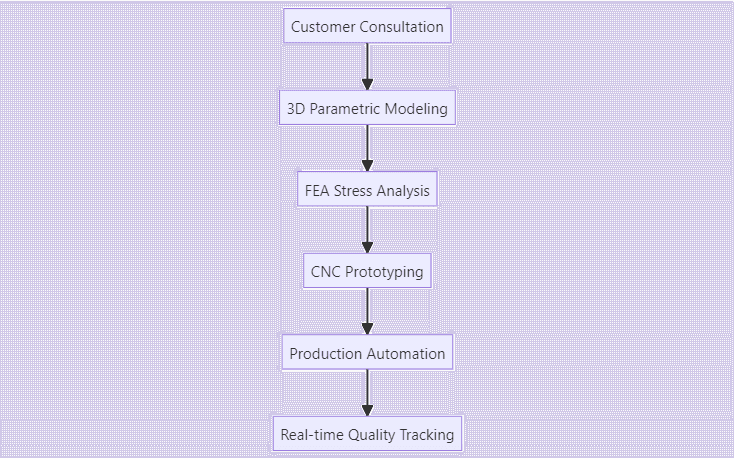

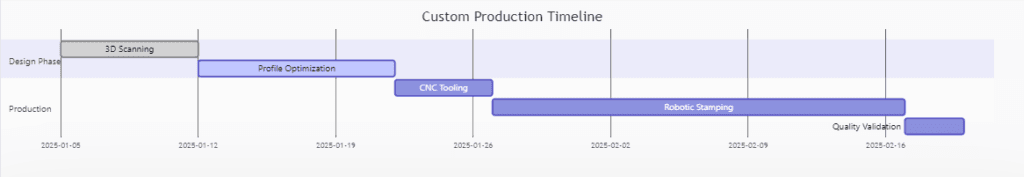

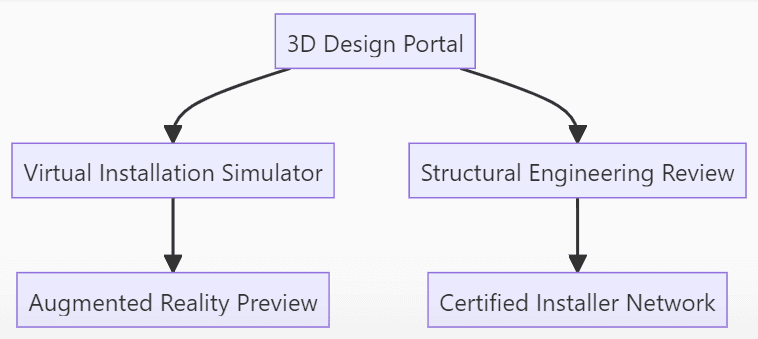

3.定制引擎:从概念到生产

设计与制造生态系统

能力矩阵:

| 参数 | 行业标准 | SKW 优势 |

|---|---|---|

| 简介选项 | 5-8 个设计 | 87+ 个简介 |

| 色彩搭配 | 10 种 RAL 颜色 | 无限潘通 |

| 订购数量 | 5000 m² | 100 m² |

| 准备时间 | 60-90 天 | 15-21 天 |

生产车间智能系统

物联网集成:

- 每条生产线 217 个传感器

- 机器学习预测性维护

- 每 0.8 秒自动调整一次

案例研究:豪华酒店定制

案例:澳门威尼斯人度假村 挑战:用现代技术复制 17 世纪的兵马俑 解决方案:

成果:

- 色彩精度:ΔE 0.8(人眼不可见)

- 生产速度:比传统方法快 3 倍

- 减少浪费:92% 与人工流程的对比

质量认证优势

| 标准 | 要求 | SKW 性能 |

|---|---|---|

| ISO 9001:2015 | 加工能力 >1.33 | Cpk=2.15 |

| 迈阿密-戴德 TAS-100 | 风升力 >90 psf | 300 psf |

| ASTM D3468 | 颗粒损失 <3g | 0.5g |

| EN 13501-5 | A 级防火 | 超过 A1 级 |

生产比较分析

定制技术细分

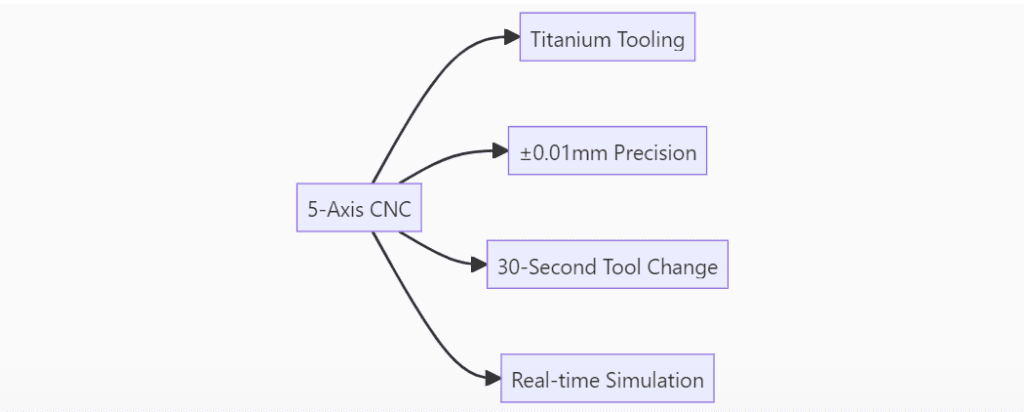

数控加工中心能力

材料创新:

- 针对独特环境的定制合金开发

- 混合材料集成(铜质材料 + 钢材)

- 针对不同地区的配方(沿海地区与工业地区)

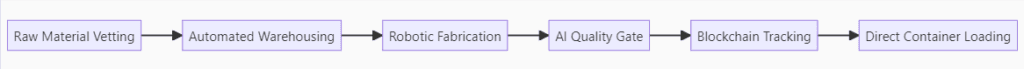

供应链整合

准时制生产流程

提高效率:

- 99.3% 准时交货

- 15 天全球送货保证

- 零定制附加费

全球技术支持

从设计到安装的生态系统

包括的服务:

- 针对气候的性能建模

- 安装机器人兼容性

- BIM 对象库

- 持续的产品监测

下载卓越制造产品组合

认证:ISO 9001:2015 - ISO 14001 - UL 认证 - FM 全球认可 - CE 标志

专利:CN201830573459.X(自动冲压) - US202410213164(纳米固化工艺) - EP4158657B1(定制 CNC 系统)