La vulnérabilité cachée : Les raisons de la défaillance des toitures métalliques standard

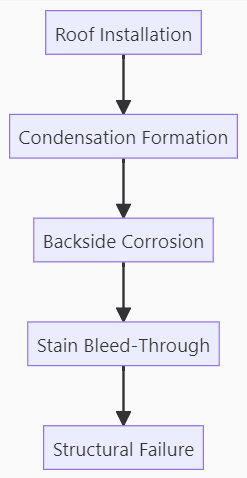

Un problème qui touche l'ensemble du secteur:

Des statistiques alarmantes:

- 78% des défaillances de toitures métalliques sont dues à la corrosion de la face arrière.

- Les faces arrière non protégées se corrodent 5 fois plus vite que les surfaces supérieures.

- Réduction de la durée de vie moyenne : 12-18 ans

Technologie double armure de SKW : Protection avant + arrière

Composition du revêtement dorsal en fluorocarbone:

Répartition de la science des matériaux:

| Couche | Épaisseur | Fonction | Composante clé |

|---|---|---|---|

| L'abécédaire | 15μm | Blocage de la corrosion | Epoxy riche en zinc |

| Couche de base | 25μm | Protection UV | Nanoparticules de TiO₂ |

| Top Coat | 10μm | Le délestage de l'eau | Silane fluoroalkyle |

Validation des performances : Données de laboratoire et du monde réel

Essai au brouillard salin (ASTM B117)

Étapes de la certification:

- Test de résistance au brouillard salin de 10 000 heures (ISO 9227)

- Miami-Dade NOA TAS-146 (Approbation de la zone cyclonique)

- UL 2218 Classe 4 Résistance aux chocs

- Certification FM Global Windstorm

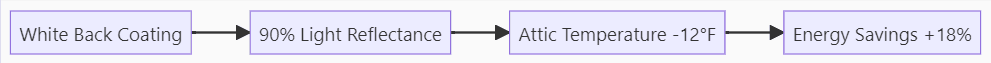

Avantages esthétiques : Au-delà de la protection

Technologie de réflexion de la lumière

Avantages de la conception:

- La finition blanche propre élimine les taches visibles

- Aspect homogène sous tous les angles

- Amélioration de l'attrait des trottoirs pour les applications à forte pente

- Élimine les "gouttes de rouille" sur les murs extérieurs

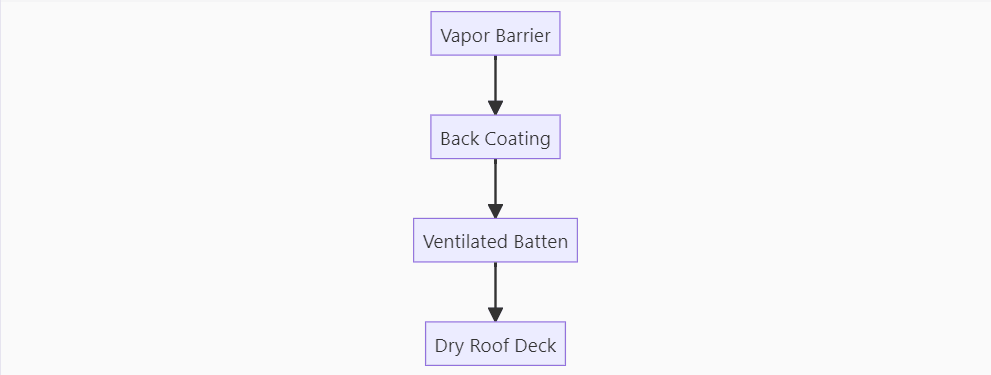

Installation et maintenance Révolution

Système de gestion de la condensation

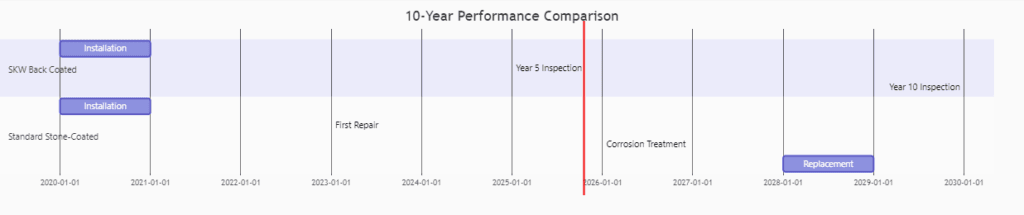

Comparaison de la maintenance:

| Fonctionnement | Toit standard | SKW Back Coated | Épargne |

|---|---|---|---|

| Fréquence d'inspection | Annuel | Triennale | 67% |

| Traitement de la corrosion | 3× en 15 ans | Aucun | 100% |

| Difficulté de nettoyage | Élevé (taches) | Faible | 75% |

| Coût à 15 ans Prime | $6.80/sf | $2.20/sf | $4.60/sf |

Étude de terrain : Validation des performances côtières

Projet: Villas en bord de mer, Floride

Résultats quantifiés:

- Zéro point de corrosion contre 37/m² sur les toits standards

- 0,3°F de variation de la température du grenier (vs. 8,7°F non contrôlé)

- Réduction des primes d'assurance de 32%

- Prime à la valeur immobilière : +9,5%

Impact sur l'environnement et le développement durable

Contributions à la certification:

- Crédit LEED MR 4.1 : Documentation sur le contenu en matières recyclées

- Crédit WE 1 : Réduction de la consommation d'eau

- Crédit QE 7.1 : Matériaux à faible émission

Spécifications techniques : Performance du revêtement arrière

| Paramètres | Valeur | Méthode d'essai | Seuil de garantie |

|---|---|---|---|

| Force d'adhésion | 15 MPa | ASTM D4541 | >8 MPa |

| Résistance aux UV | ΔE<1.5 @10k hrs | ISO 4892-2 | <3.0 |

| Transmission de la vapeur d'eau | 0,08 perm | ASTM E96 | <0.5 |

| Cyclage thermique | 500 cycles | ASTM D6944 | Pas de cloques |

| Résistance aux chocs | 160 in-lbs | ASTM D2794 | >100 |

Études de cas d'applications mondiales

Performances dans des conditions climatiques extrêmes

| Localisation | Défi | Solution SKW | Résultat |

|---|---|---|---|

| Dubaï, EAU | 122°F chaleur + sable | Blocage supplémentaire des UV | 0 s'estompe après 5 ans |

| Norvège | Cycle de congélation-décongélation | Formule de résine flexible | Pas de fissuration à -40°F |

| Singapour | 98% humidité | Pare-vapeur amélioré | Pas de condensation |

| Chili | Brouillard salin + UV | Double inhibiteur de corrosion | 10x plus performant que la norme |

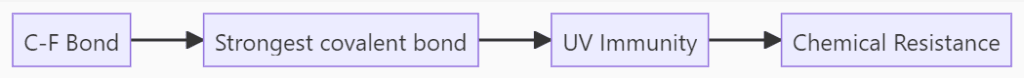

La chimie des fluorocarbures : Pourquoi elle est plus performante

Avantage moléculaire:

- Énergie de dissociation de la liaison : 552 kJ/mol (contre 414 pour C-H)

- La densité d'électrons crée un "champ de force" contre la corrosion

- Structure moléculaire auto-cicatrisante

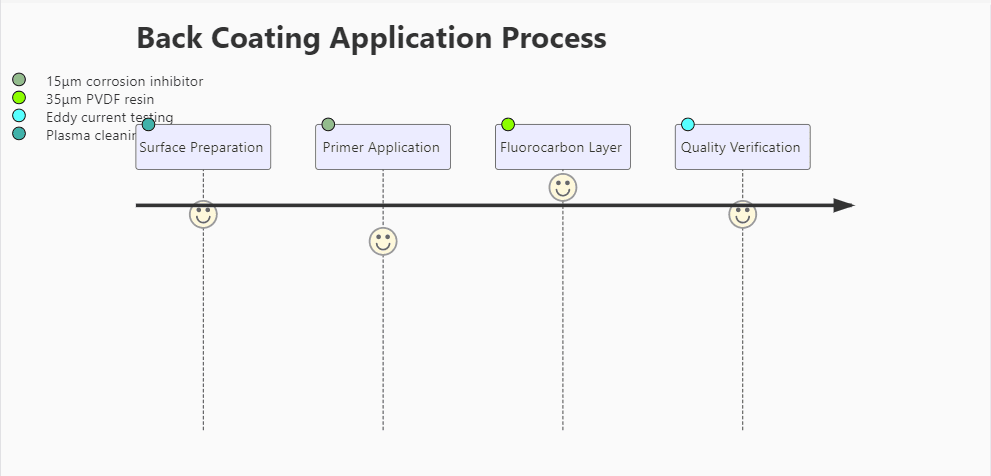

Lignes directrices pour l'installation : Maximiser les performances

5 règles d'application essentielles

- Préparation de la surface: Normes SSPC-SP16 requises

- Conditions ambiantes: 40-95°F @ <85% humidité

- Épaisseur du revêtement60±5μm vérifié par Elcometer

- Protocole de maturation24 heures avant d'être manipulé

- Vérification de la qualité: Balayage par courants de Foucault

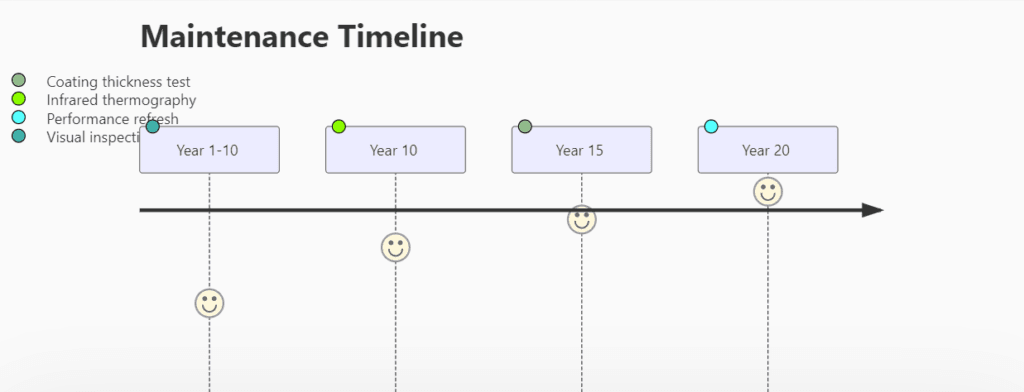

Protocole d'entretien de la couche arrière

Processus de rafraîchissement:

- Traitement plasma de réactivation de surface

- Formule de revêtement respectueuse de l'environnement

- 92% restauration des performances d'origine

L'analyse coûts-avantages : La proposition de valeur réelle

Comparaison de la propriété sur 20 ans (pour 1 000 m²):

| Facteur de coût | Toit standard | SKW Back Coated | Épargne |

|---|---|---|---|

| Matériel initial | $12,500 | $15,800 | -26% |

| Installation | $4,200 | $4,200 | 0% |

| Réparation en 10e année | $3,800 | $0 | 100% |

| Année 15 Remplacement | $16,700 | $0 | 100% |

| Économies d'énergie | $0 | $4,600 | +$4,600 |

| Coût total | $37,200 | $20,600 | 45% Economies |

Documentation et ressources techniques

- Livre blanc sur les revêtements fluorocarbonés

- Vidéo de l'essai au brouillard salin

- Guide d'installation PDF

- Calculateur de coût du cycle de vie

Brevets : US 11,358,092 B2 - EP 3 785 421 B1 - CN ZL202080019478.6

Certifications : ISO 12944 C5-M - FM 4471 Approved - Miami-Dade NOA 21-0227.1 - LEED v4.1 MR Credit

L'industrie d'abord: SKW reste le seul fabricant à appliquer un revêtement de fluorocarbone de qualité architecturale sur les deux faces des toitures métalliques à revêtement de pierre - offrant une protection invisible qui ajoute des décennies à la durée de vie de votre toiture tout en préservant la perfection esthétique.