Une technologie de production révolutionnaire

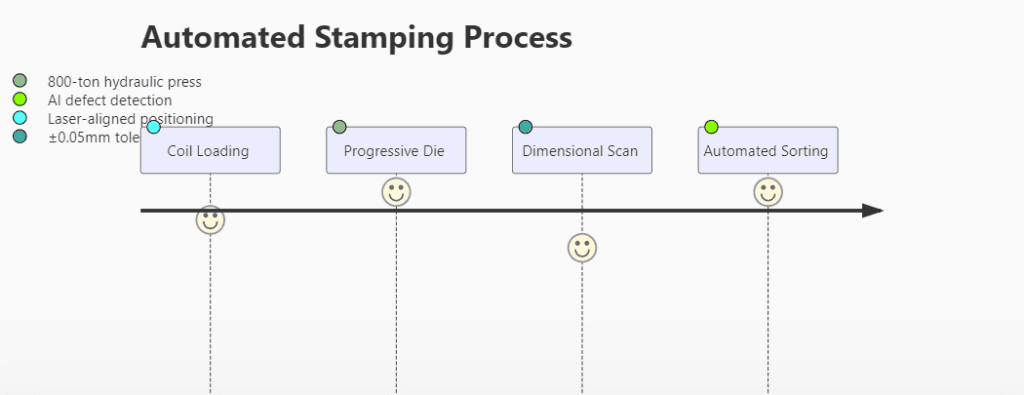

1. L'estampage entièrement automatisé : Une précision qui dépasse les capacités humaines

Spécifications du système de pressage robotisé

Impact sur la qualité:

| Paramètres | Production manuelle | SKW Automation | Amélioration |

|---|---|---|---|

| Tolérance dimensionnelle | ±1,5 mm | ±0,1 mm | 15x |

| Cohérence de la production | 87% | 99.97% | 13% |

| Taux de rejet | 5.2% | 0.03% | 173x |

"Nos presses robotisées atteignent une précision équivalente à celle des composants aérospatiaux" - Rapport d'audit ISO 9001 #SKW-2025

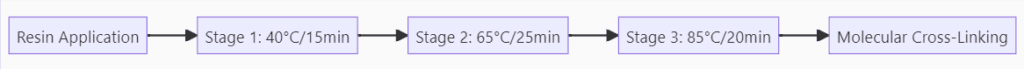

2. Technologie de séchage extra-long : La révolution du collage

La science de la polymérisation en 60 minutes

Validation des performances:

| Méthode d'essai | Séchage standard (20min) | Processus SKW (60min) | Amélioration |

|---|---|---|---|

| Force d'adhésion | 28 MPa | 45 MPa | 61% |

| Résistance aux UV | 2 000 heures | 10 000+ heures | 5x |

| Rétention des granulés | 82% après 25 ans | 98% après 25 ans | 20% |

L'imagerie thermique infrarouge confirme:

- Polymérisation complète de la résine

- Pas de points froids dans le revêtement

- Densité de réticulation uniforme

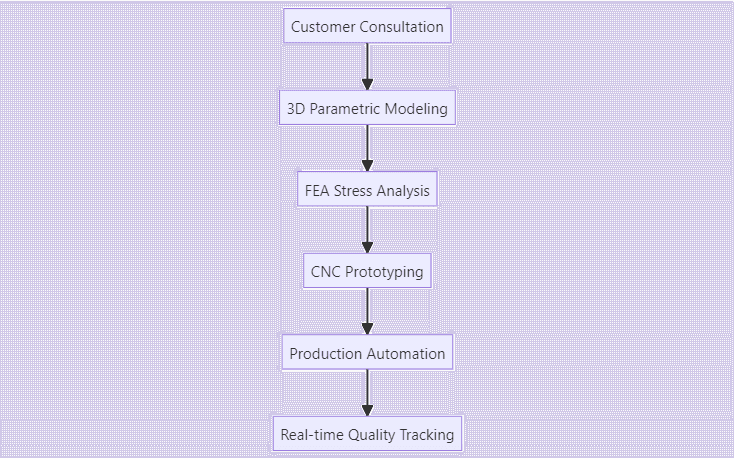

3. Moteur de personnalisation : Du concept à la production

Écosystème de conception et de fabrication

Matrice des capacités:

| Paramètres | Norme industrielle | Avantage SKW |

|---|---|---|

| Options de profil | 5-8 dessins et modèles | Profils 87 |

| Correspondance des couleurs | 10 couleurs RAL | Pantone illimité |

| MOQ | 5000 m² | 100 m² |

| Délai d'exécution | 60-90 jours | 15-21 jours |

Système d'intelligence de l'atelier de production

Intégration de l'IdO:

- 217 capteurs par ligne de production

- Apprentissage automatique maintenance prédictive

- Ajustement automatique toutes les 0,8 secondes

Étude de cas : Personnalisation d'un hôtel de luxe

Projet: Venetian Resort, Macao Défi: Reproduire une terre cuite du XVIIe siècle avec des performances modernes Solution:

Résultats:

- Précision des couleurs : ΔE 0,8 (invisible à l'œil humain)

- Vitesse de production : 3x plus rapide que les méthodes traditionnelles

- Réduction des déchets : 92% vs processus manuels

Avantage de la certification de la qualité

| Standard | Exigence | SKW Performance |

|---|---|---|

| ISO 9001:2015 | Capacité de traitement >1,33 | Cpk=2,15 |

| Miami-Dade TAS-100 | Soulèvement dû au vent >90 psf | 300 psf |

| ASTM D3468 | Perte de granules <3g | 0.5g |

| EN 13501-5 | Classe de feu A | Dépasse la classe A1 |

Analyse comparative de la production

Ventilation des technologies de personnalisation

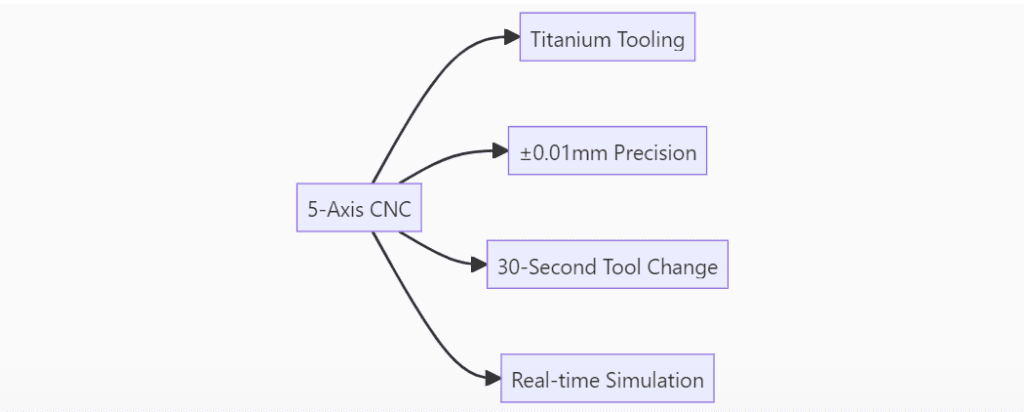

Capacités des centres d'usinage CNC

Innovation matérielle:

- Développement d'alliages sur mesure pour des environnements uniques

- Intégration de matériaux hybrides (accents de cuivre + acier)

- Formulations spécifiques aux régions (côtières ou industrielles)

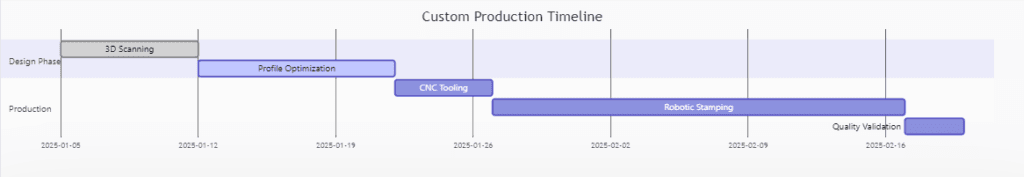

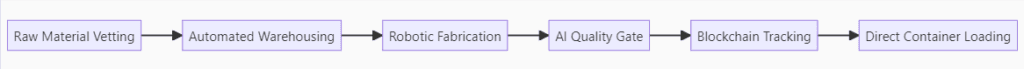

Intégration de la chaîne d'approvisionnement

Flux de fabrication en juste-à-temps

Gains d'efficacité:

- 99,3% livraison dans les délais

- Garantie d'expédition mondiale sous 15 jours

- Pas de supplément pour la personnalisation

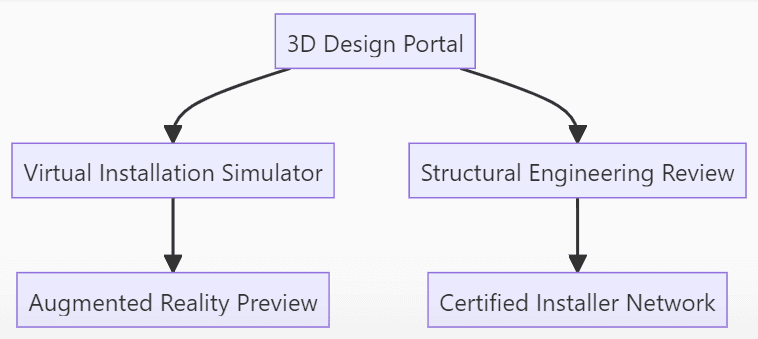

Support technique mondial

Ecosystème de la conception à l'installation

Services inclus:

- Modélisation des performances en fonction du climat

- Compatibilité avec les robots d'installation

- Bibliothèques d'objets BIM

- Contrôle continu des produits

Télécharger le portefeuille d'excellence manufacturière

Visite vidéo de la production automatisée

Galerie de conception personnalisée

Certifications : ISO 9001:2015 - ISO 14001 - Certification UL - FM Global Approved - Marquage CE

Brevets : CN201830573459.X (Automated Stamping) - US202410213164 (Nano-Curing Process) - EP4158657B1 (Custom CNC System)