Toitures métalliques sont un choix populaire pour les propriétaires et les entreprises, car ils sont durables, économes en énergie et résistants. Mais une question hante de nombreux acheteurs : Le revêtement de zinc prévient-il la rouille ?

La réponse est courte : Oui, quand c'est bien fait. Le revêtement de zinc est l'un des moyens les plus efficaces de protéger le métal contre la corrosion, mais tous les revêtements de zinc ne se valent pas. En tant que fabricant chinois de premier plan de toits métalliques revêtus de pierre (https://skwroof.com/), nous avons perfectionné l'art de combiner le revêtement de zinc avec des granules de pierre naturelle pour créer des toits qui résistent à la rouille pendant des décennies, même dans des environnements difficiles tels que les zones côtières ou industrielles.

Dans ce guide complet, nous expliquons comment fonctionne le revêtement de zinc, pourquoi notre alliage aluminium-zinc (AZ150) Nous verrons également comment notre revêtement en pierre surpasse le zinc traditionnel et comment notre technologie de revêtement en pierre fait passer la protection contre la rouille à un niveau supérieur. Nous partagerons également des données réelles, des résultats de tests et des études de cas qui prouvent que nos toits sont conçus pour durer.

Chapitre 1 : Comment le revêtement de zinc prévient la rouille - la science

Pour comprendre pourquoi le revêtement de zinc est efficace, commençons par les principes de base de la corrosion. La rouille (oxyde de fer) se forme lorsque le fer ou l'acier réagit avec l'oxygène et l'humidité. Le zinc, un métal plus "actif" que le fer, agit comme un anode sacrificielleIl se corrode en premier, protégeant ainsi l'acier sous-jacent de la rouille.

1.1 Les deux principaux mécanismes de l'enduction de zinc

Le revêtement de zinc prévient la rouille grâce à deux processus complémentaires :

Protection des barrières: Le zinc forme une couche d'oxyde mince et dense (ZnO) à sa surface lorsqu'il est exposé à l'air. Cette couche agit comme une barrière physique, empêchant l'oxygène et l'humidité d'atteindre l'acier.

Protection par anode sacrificielle: Le zinc est plus électrochimiquement réactif que l'acier. Lorsqu'il est exposé à l'humidité, le zinc libère des électrons qui "alimentent" le processus de corrosion, laissant l'acier intact. C'est pourquoi l'acier zingué (acier galvanisé) est souvent qualifié d'"autosacrificiel".

1.2 L'importance de l'épaisseur et de la qualité

Toutes les couches de zinc ne se valent pas. L'efficacité du revêtement de zinc dépend de deux facteurs :

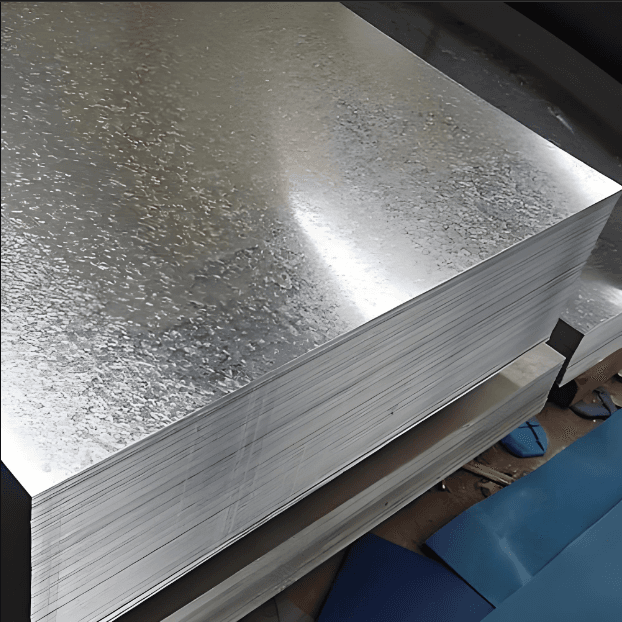

Uniformité: Une couche de zinc inégale laisse des "points faibles" où la rouille peut se développer. Nous utilisons galvanisation à chaud-L'acier est plongé dans du zinc en fusion afin d'obtenir un revêtement uniforme et adhérent.

Épaisseur: Plus la couche de zinc est épaisse, plus elle protège l'acier longtemps. Les normes industrielles pour l'acier galvanisé vont de 80g/㎡ à 150g/㎡. Nos toits utilisent 150g/㎡ Alliage d'aluminium et de zinc AZ150-30% plus épais que l'acier galvanisé moyen.

1.3 Essais en conditions réelles : Résistance au brouillard salin

Pour prouver l'efficacité de notre revêtement de zinc, nous avons soumis nos panneaux d'acier à un test de résistance à la corrosion. Essai au brouillard salin de 3000 heures (ASTM B117) - une simulation d'environnements côtiers ou industriels. Voici leurs performances :

- Notre alliage aluminium-zinc AZ150: Aucune rouille visible après 3000 heures. La couche d'oxyde est restée intacte et l'acier sous-jacent a été complètement protégé.

- Acier galvanisé standard (80g/㎡): La rouille est apparue après 1200 heures. La couche de zinc s'est corrodée de manière inégale, mettant l'acier à nu.

- Acier non revêtu: La rouille se forme dans les 24 heures.

Conclusion: Notre revêtement de zinc est 2,5 fois plus résistant au brouillard salin que l'acier galvanisé standard.

Chapitre 2 : Pourquoi notre alliage aluminium-zinc (AZ150) est-il meilleur que le zinc pur ?

Le zinc pur est efficace pour prévenir la rouille, mais il a ses limites, en particulier dans les environnements difficiles. C'est pourquoi nous utilisons Alliage aluminium-zinc AZ150-Un mélange d'aluminium 55%, de zinc 43,5% et de silicium 1,5% pour nos toitures métalliques. Voici pourquoi il est supérieur :

2.1 Résistance accrue à la corrosion

L'aluminium forme un couche d'oxyde plus dure et plus durable (Al₂O₃) que le zinc. Combinée au zinc, cette couche :

Prolonge la durée de vie du revêtement de zinc de 50% par rapport au zinc pur.

Résiste aux rayures et à l'abrasion (essentiel pour les toits recouverts de pierres, sur lesquels on marche pendant l'installation).

Assure une meilleure protection contre les pluies acides et les polluants industriels.

2.2 Une meilleure formabilité

Le zinc pur est cassant et peut se fissurer lorsqu'il est plié. Notre alliage AZ150 est plus souple, ce qui le rend idéal pour former les panneaux incurvés ou emboîtés utilisés dans les toits revêtus de pierre. Cela signifie que nos toitures peuvent être installées sur des formes de toit complexes (comme les pignons ou les croupes) sans compromettre le revêtement de zinc.

2.3 Rentabilité à long terme

Si l'alliage AZ150 est plus cher que le zinc pur au départ, il permet d'économiser de l'argent à long terme. Nos toits ont une Durée de vie de 50 ans (contre 20 à 30 ans pour l'acier galvanisé standard), de sorte que vous n'aurez pas à remplacer votre toit aussi souvent.

Chapitre 3 : Comment le revêtement en pierre fait passer la protection contre la rouille au niveau supérieur

La couche de zinc est excellente, mais elle ne suffit pas à elle seule, en particulier pour les toits qui sont exposés aux éléments 24 heures sur 24, 7 jours sur 7. C'est pourquoi nous ajoutons un revêtement en granulés de pierre naturelle à nos panneaux métalliques. Voici comment cela fonctionne :

3.1 Barrière physique contre les dommages

Les granulés de pierre naturelle (basalte ou basalte) sont :

- Dur: Dureté Mohs de 7 (identique à celle du quartz), ce qui leur permet de résister aux rayures et aux chocs (comme la grêle ou les branches d'arbre).

- Résistant à l'abrasion: Ne s'use pas, même après des décennies de passage ou d'intempéries.

- Stable aux UV: Ne se décolore pas et ne se dégrade pas à la lumière du soleil (contrairement aux revêtements en plastique).

Cette couche protège le revêtement de zinc contre les rayures et l'usure, prolongeant ainsi sa durée de vie. 20-30 ans.

3.2 Protection chimique contre la corrosion

Notre revêtement de pierre est collé sur le panneau métallique à l'aide d'une couche d'apprêt. Résine acrylique stable aux UV. Cette résine :

Améliore l'adhérence: Les granulés de pierre restent en place pendant des décennies.

Scelle le revêtement de zinc: Empêche l'humidité et l'oxygène d'atteindre le zinc.

Résiste aux produits chimiques: Protège contre les pluies acides, les fientes d'oiseaux et les polluants industriels.

Chapitre 4 : Comparaison des options de revêtement de zinc - Quelle est la meilleure solution pour vous ?

Pour vous aider à choisir la meilleure protection antirouille pour votre toiture métallique, nous avons comparé trois options courantes :

| Type de revêtement | Résistance à la corrosion | Durée de vie | Coût | Meilleur pour |

|---|---|---|---|---|

| Zinc pur (80g/㎡) | Modéré (1200 heures de brouillard salin) | 20-30 ans | Faible | Climats doux (pas de sel ni de pollution industrielle) |

| AZ150 Aluminium-Zinc (150g/㎡) | Élevée (3000 heures de brouillard salin) | 40-50 ans | Moyen | Zones côtières/industrielles |

| AZ150 + revêtement en pierre | Extrême (5000+ heures de brouillard salin) | 50 ans et plus | Haut | Maisons exposées aux ouragans, maisons côtières ou maisons de luxe |

Notre recommandation: Si vous voulez un toit qui durera des décennies sans rouiller, choisissez Alliage aluminium-zinc AZ150 + revêtement en pierre. C'est l'option la plus durable et cela vaut la peine d'investir pour réaliser des économies à long terme.

Chapitre 5 : Mythes courants sur l'enduction de zinc - réfutés

5.1 "Le revêtement de zinc s'effritera avec le temps".

Faux. Notre revêtement de zinc est appliqué à l'aide de galvanisation à chaudLe zinc est ensuite appliqué sur l'acier à l'aide d'un procédé qui le lie à l'acier au niveau moléculaire. Cela signifie que le revêtement de zinc ne s'écaille pas et ne se détache pas, même si la toiture est exposée à des températures extrêmes ou à des chocs.

5.2 "Le revêtement en zinc est réservé aux toits industriels".

Faux. Nos toitures métalliques revêtues de pierre sont conçues pour un usage résidentiel et commercial. Elles sont disponibles dans une variété de styles (tuile espagnole, ardoise, bardeau) et de couleurs (rouge, gris, brun) pour s'adapter à l'esthétique de chaque maison.

5.3 "L'enduction de zinc est coûteuse".

C'est vrai. Mais au fil du temps, cela revient moins cher que de remplacer un toit rouillé. Nos toits ont une Durée de vie de 50 ans (contre 20 ans pour l'asphalte), ce qui vous permet d'économiser de l'argent à long terme. De plus, nos toits sont économes en énergie : ils réfléchissent 85% de rayonnement solaire, ce qui permet de réduire les coûts de climatisation de 20 à 30%.

Chapitre 6 : Comment choisir une toiture en métal zingué - notre guide d'achat

Si vous êtes prêt à investir dans un toit métallique résistant à la rouille, voici ce qu'il faut rechercher :

6.1 Vérifier le type et l'épaisseur du revêtement de zinc

- Type: Choisissez l'alliage aluminium-zinc (AZ150) plutôt que le zinc pur.

- Épaisseur: Rechercher au moins 150g/㎡ (notre norme).

6.2 Vérifier la qualité du revêtement de la pierre

- Matériau: Granulés de basalte naturel (pas de plastique).

- Collage: Résine acrylique (pas d'asphalte bon marché).

- Garantie: Au moins 25 ans pour le revêtement en pierre.

6.3 Recherche de certifications

- ISO 9001: Assurer la qualité de la fabrication.

- ASTM A792: Norme pour l'acier revêtu d'aluminium et de zinc.

- Miami-Dade NOA: Résistance au vent et à la corrosion (important pour les régions sujettes aux ouragans).

6.4 Demander les résultats des tests

Résistance aux UV: Au moins 25 ans (notre revêtement de pierre répond à cette exigence).

Essai au brouillard salin: Au moins 3000 heures (notre norme).

Test d'impact: Classe 4 (résiste à une grêle de 2 pouces).

Chapitre 7 : Pourquoi choisir SKW Roofing ?

Nous ne sommes pas seulement un fabricant, nous sommes un spécialiste des toits antirouille. Voici pourquoi des milliers de propriétaires et d'entreprises nous choisissent :

7.1 Durabilité imbattable

- Revêtement de zinc: 150g/㎡ Alliage aluminium-zinc AZ150 (30% plus épais que la norme industrielle).

- Revêtement de pierre: Granulés de basalte naturel liés à une résine stable aux UV (garantie de 25 ans).

- Durée de vie: 50+ ans (deux fois plus longtemps qu'une toiture traditionnelle en asphalte).

7.2 Performances supérieures

- Résistance au vent: 150mph (peut résister aux ouragans de catégorie 4).

- Résistance aux chocs: Classe 4 (résiste à une grêle de 2 pouces).

- Efficacité énergétique: Réfléchit 85% de rayonnement solaire (réduit les coûts de refroidissement de 20 à 30%).

7.3 Options de personnalisation

- Styles: Tuiles espagnoles, ardoise, bardeaux, panneaux plats modernes.

- Couleurs: 30+ options (y compris des couleurs personnalisées).

- Profils: Courbe, emboîtement ou plat - parfait pour toute forme de toit.

7.4 Transparence des prix et des services

- Prix directs d'usine: Pas d'intermédiaires - économie de 15-20% par rapport à la vente au détail.

- Échantillons gratuits: Nous vous enverrons un échantillon de notre toiture afin que vous puissiez vous rendre compte de sa qualité.

- Installation professionnelle: Nos installateurs certifiés s'assurent que votre toit est installé correctement (garantie d'installation de 10 ans).

Chapitre 8 : Conclusion - L'enduit de zinc fonctionne, mais nos toits fonctionnent mieux

Pour répondre à la question : Oui, le revêtement en zinc empêche la rouille-mais seulement si c'est bien fait. Notre combinaison d'alliage aluminium-zinc AZ150 et de revêtement en pierre est le moyen le plus efficace de protéger votre toiture métallique de la rouille, de la corrosion et des dommages causés par les intempéries.

Si vous en avez assez des toits rouillés, des coûts d'entretien élevés et des durées de vie courtes, il est temps de passer à SKW Roofing. Nous sommes le seul fabricant qui combine :

- Revêtement en zinc haut de gamme (150g/㎡ AZ150).

- Revêtement en pierre naturelle (garantie de 25 ans).

- Plus de 50 ans de performance sans rouille.

Appel à l'action

Prêt à obtenir un toit résistant à la rouille qui durera des décennies ? Visitez notre site web (https://skwroof.com/) à :

- Parcourir nos produits: Voir notre gamme complète de toits métalliques revêtus de pierre.

- Demander un échantillon: Touchez et sentez la qualité de nos matériaux.

- Obtenir un devis gratuit: Nous vous donnerons un prix direct pour votre toiture.

N'attendez pas que votre toit commence à rouiller - investissez dans SKW Roofing aujourd'hui et profitez d'une tranquillité d'esprit pendant plus de 50 ans.